Ultimately, the price of a porcelain furnace is determined by its technical capabilities and build quality. The most significant cost drivers are the sophistication of the heating technology, the size of the firing chamber, and the degree of software programmability, as these directly impact the range of materials you can process and the efficiency of your workflow.

The search for a porcelain furnace is not about finding the cheapest option. It's about identifying the specific combination of heating precision, capacity, and control that matches your lab's current and future material needs, ensuring a return on your investment through quality and efficiency.

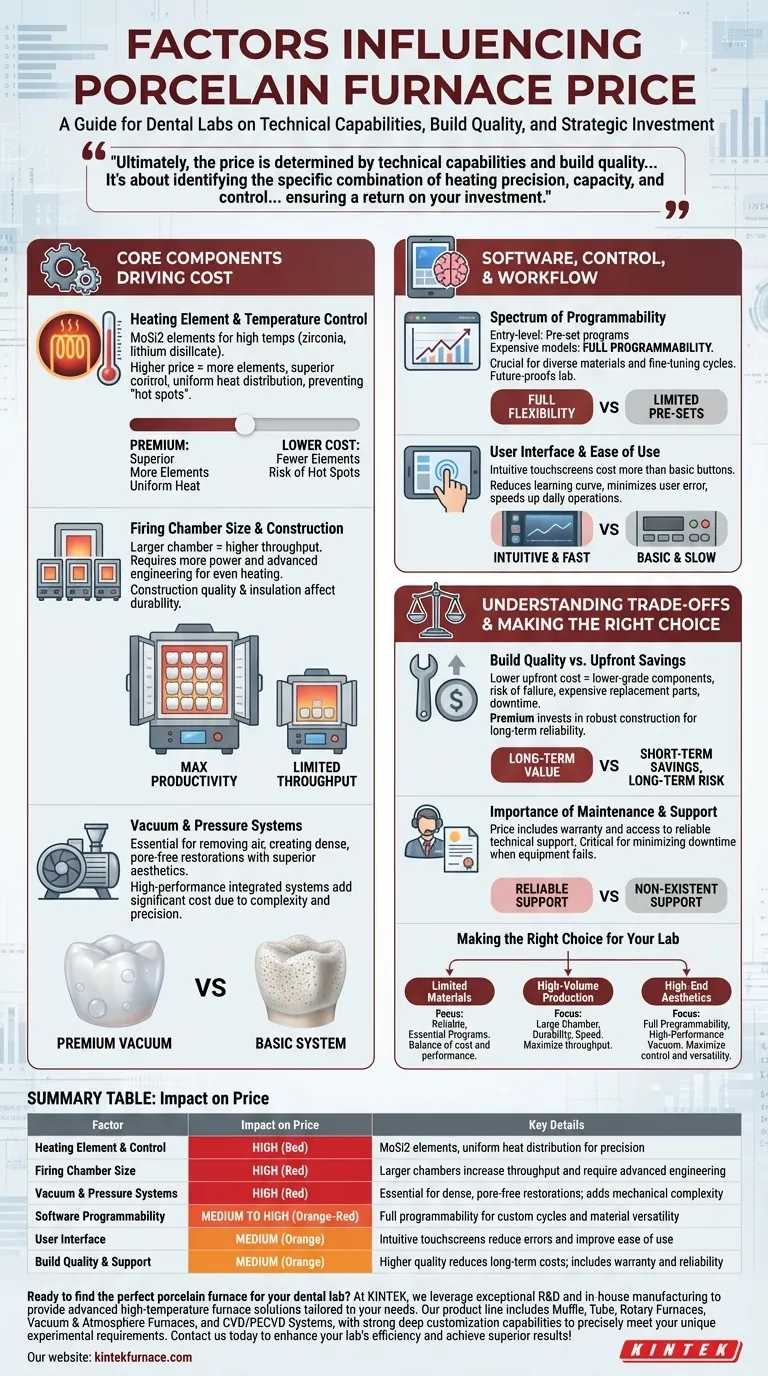

The Core Components Driving Cost

The fundamental hardware of the furnace is the primary determinant of its base price. More advanced and durable components command a higher investment because they deliver greater precision and reliability.

Heating Element and Temperature Control

The heating element is the heart of the furnace. Most modern units use molybdenum disilicide (MoSi2) elements, known for their ability to reach and maintain the high temperatures required for materials like zirconia and lithium disilicate.

The price increases with the quality and number of these elements. Premium furnaces feature superior elements and more sophisticated temperature controllers that ensure uniform heat distribution and prevent "hot spots," which is critical for consistent, high-quality restorations.

Firing Chamber Size and Construction

The internal volume of the firing chamber directly impacts your lab's throughput. A larger chamber can fire more units simultaneously, increasing productivity.

However, a larger chamber requires more power and more advanced engineering to heat evenly, which significantly raises the manufacturing cost. The construction quality, including the type of insulation used, also plays a key role, affecting both heat retention and the furnace's long-term durability.

Vacuum and Pressure Systems

The inclusion of a vacuum pump is a major price differentiator. A vacuum system is essential for firing many types of dental ceramics, as it removes air from the chamber to create dense, pore-free restorations with superior aesthetics.

Furnaces with integrated, high-performance vacuum systems are more expensive due to the added mechanical complexity and the precision controls required to manage the vacuum cycles.

Software, Control, and Workflow

Beyond the core hardware, the furnace's "brain" and user interface have a profound impact on its price, usability, and versatility.

The Spectrum of Programmability

Entry-level furnaces may come with a few pre-set programs for common materials. More expensive models offer full programmability, allowing technicians to create, store, and modify an unlimited number of custom firing cycles.

This flexibility is crucial for labs that work with a wide range of materials or want to fine-tune cycles for optimal results. Advanced software justifies a higher price by future-proofing the lab for new and emerging dental materials.

User Interface and Ease of Use

A furnace with a simple, intuitive touchscreen interface will cost more than one with basic buttons and a small digital display. While this may seem like a luxury, a good user interface reduces the learning curve, minimizes the risk of user error, and speeds up daily operations.

Understanding the Trade-offs and Hidden Costs

A lower upfront price can often lead to higher long-term expenses and operational headaches. Acknowledging these trade-offs is central to making a sound investment.

Build Quality vs. Upfront Savings

Less expensive furnaces often use lower-grade components, from the heating elements to the electronic controls and thermocouple. While this reduces the initial purchase price, it increases the risk of premature failure.

Downtime for repairs and the cost of replacement parts, especially heating elements, can quickly erase any initial savings. Premium brands invest in robust construction, justifying their price through superior reliability and a longer operational lifespan.

The Importance of Maintenance and Support

The price of a furnace often includes the manufacturer's warranty and access to technical support. A cheaper unit from a lesser-known brand may come with a limited warranty and non-existent support.

When a critical piece of equipment fails, having reliable, accessible support and readily available spare parts is invaluable. This long-term security is a hidden but critical part of the furnace's total cost.

Making the Right Choice for Your Lab

Your decision should be guided by your specific operational needs, not just the sticker price.

- If your primary focus is a limited range of common materials: A reliable furnace from a reputable brand with essential pre-set programs offers the best balance of cost and performance.

- If your primary focus is high-volume production: Prioritize a larger firing chamber and a furnace known for its durability and speed to maximize throughput.

- If your primary focus is high-end aesthetic restorations and diverse materials: Invest in a furnace with full programmability and a high-performance vacuum system to achieve maximum control and versatility.

Ultimately, the right furnace is a strategic asset that enhances your lab's capabilities and supports its growth.

Summary Table:

| Factor | Impact on Price | Key Details |

|---|---|---|

| Heating Element & Control | High | MoSi2 elements, uniform heat distribution for precision |

| Firing Chamber Size | High | Larger chambers increase throughput and require advanced engineering |

| Vacuum & Pressure Systems | High | Essential for dense, pore-free restorations; adds mechanical complexity |

| Software Programmability | Medium to High | Full programmability for custom cycles and material versatility |

| User Interface | Medium | Intuitive touchscreens reduce errors and improve ease of use |

| Build Quality & Support | Medium | Higher quality reduces long-term costs; includes warranty and reliability |

Ready to find the perfect porcelain furnace for your dental lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab