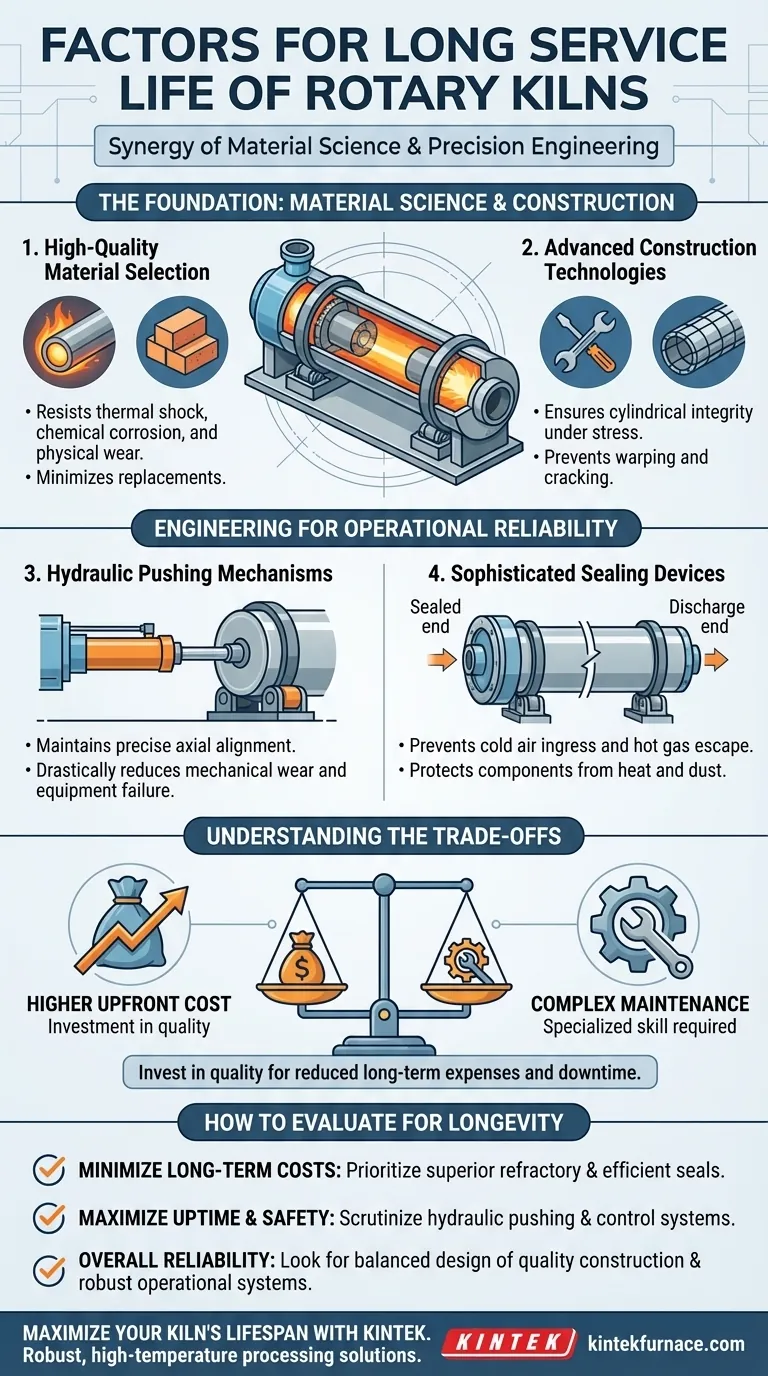

The long service life of a rotary kiln is a direct outcome of specific engineering choices focused on material durability and operational stability. It is achieved through the use of high-quality, resilient materials, advanced construction technologies, and the integration of sophisticated mechanical systems designed to manage operational stresses.

The durability of a rotary kiln stems from a holistic design philosophy that combines robust material science with precision engineering. It is the synergy between the quality of the core components and the sophistication of its operational systems that ensures long-term reliability and cost-efficiency.

The Foundation: Material Science and Construction

A kiln's ability to withstand extreme conditions for years, or even decades, begins with its fundamental structure. The selection of materials and the precision of its assembly are the primary determinants of its operational lifespan.

High-Quality Material Selection

The core of the kiln—the shell and refractory lining—is constantly exposed to intense heat and abrasive materials. Using high-grade steel and specialized refractory bricks is non-negotiable for longevity. These materials are chosen for their ability to resist thermal shock, chemical corrosion, and physical wear, which directly minimizes the need for frequent replacements.

Advanced Construction Technologies

Modern kilns are not simply welded tubes; they are products of advanced fabrication and engineering. Precision in manufacturing ensures the kiln shell maintains its cylindrical integrity under thermal expansion and rotational stress. This structural soundness prevents warping and cracking, which are common failure points in lesser-quality equipment.

Engineering for Operational Reliability

Beyond the static components, a kiln's dynamic systems are critical for protecting it from the stresses of continuous operation. These systems actively manage alignment and sealing to prevent premature wear.

The Role of Hydraulic Pushing Mechanisms

A rotary kiln must be precisely positioned to rotate smoothly on its support rollers. A hydraulic pushing mechanism, or thrust device, continuously monitors and adjusts the kiln's axial position. This prevents the riding rings and rollers from grinding against their stops, drastically reducing mechanical wear and averting potential equipment failure.

The Critical Function of Sealing Devices

The efficiency and longevity of a kiln depend heavily on maintaining a controlled internal environment. Advanced sealing devices at the feed and discharge ends are crucial. They prevent cold air from entering the kiln and hot gases from escaping, which not only improves thermal efficiency but also protects mechanical components from heat damage and dust exposure.

Understanding the Trade-offs

While engineered for longevity, the design choices that enable it come with specific considerations that every operator must understand.

The Upfront Cost of Quality

The use of superior materials and advanced systems like hydraulic pushers results in a higher initial capital investment. This cost, however, is typically offset over the kiln's lifecycle by reduced maintenance expenses and lower downtime frequency.

The Complexity of Maintenance

Sophisticated systems require specialized knowledge. While features like advanced seals and hydraulic mechanisms enhance reliability, they also demand a higher level of skill for maintenance and repair. Proper training for your technical staff is essential to realize the full benefits of these systems.

How to Evaluate a Rotary Kiln for Longevity

When selecting or assessing a rotary kiln, your evaluation should align with your primary operational goals.

- If your primary focus is minimizing long-term operational costs: Prioritize kilns built with superior-grade refractory materials and highly efficient sealing systems to reduce fuel consumption and repair frequency.

- If your primary focus is maximizing uptime and safety: Scrutinize the design of the hydraulic pushing mechanisms and other integrated control systems that actively prevent mechanical failure.

- If your primary focus is overall reliability: Look for a balanced design where high-quality construction is supported by proven, robust operational systems.

Ultimately, a rotary kiln's service life is a direct reflection of the quality engineered into its core components and its ability to manage operational stress.

Summary Table:

| Key Factor | Contribution to Long Service Life |

|---|---|

| High-Quality Materials | Resists thermal shock, corrosion, and wear, minimizing replacements. |

| Advanced Construction | Ensures structural integrity under thermal and rotational stress. |

| Hydraulic Pushing Mechanisms | Prevents mechanical wear by maintaining precise axial alignment. |

| Sophisticated Sealing Devices | Protects components from heat and dust, improving thermal efficiency. |

Maximize your rotary kiln's lifespan and operational efficiency with KINTEK.

Backed by expert R&D and manufacturing, KINTEK offers robust, high-temperature processing solutions, including custom rotary kilns designed for superior durability and reliability. Our systems integrate the high-quality materials and advanced engineering principles detailed above to ensure your operation runs smoothly for years, reducing downtime and total cost of ownership.

Ready to invest in a kiln built to last? Contact our experts today to discuss how we can tailor a solution to your unique processing needs.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing