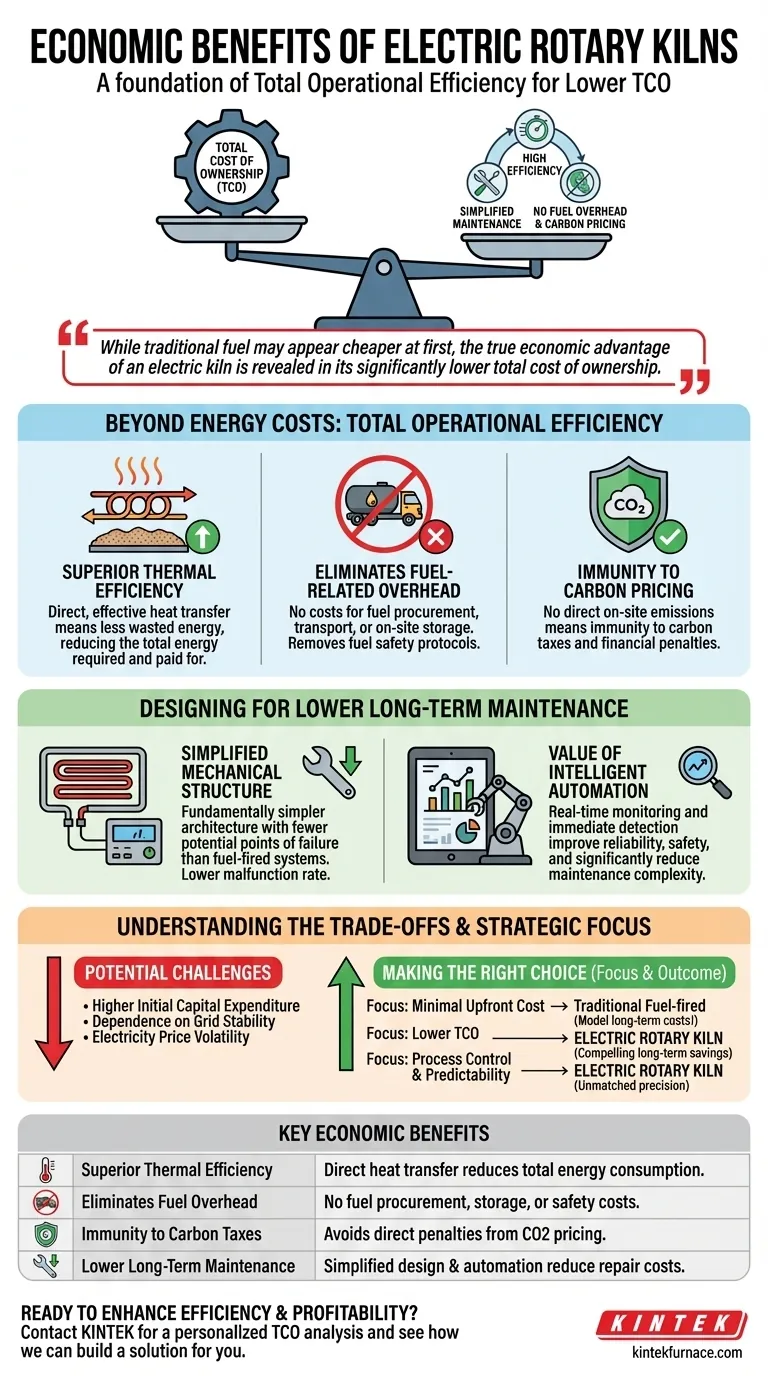

The economic case for electric rotary kilns is built on a foundation of total operational efficiency, not just the per-unit cost of energy. While electricity can seem expensive, these kilns deliver significant financial benefits through superior heat efficiency, the elimination of complex fuel logistics, and substantially lower long-term maintenance requirements, especially when factoring in the rising costs of carbon taxes.

While traditional fuel may appear cheaper at first glance, the total cost of ownership for an electric rotary kiln is often significantly lower. The true economic advantage is revealed when you account for its high efficiency, simplified maintenance, and the complete removal of fuel-related overhead and carbon pricing.

Beyond Energy Costs: A Look at Total Operational Efficiency

The financial viability of an electric kiln becomes clear when you analyze the entire operational picture, moving beyond a simple comparison of fuel versus electricity prices.

Superior Thermal Efficiency

Electric kilns, particularly those using electromagnetic induction, transfer heat far more directly and effectively to the material being processed. This high efficiency means less energy is wasted, reducing the total energy required—and paid for—to achieve the desired result.

Eliminating Fuel-Related Overhead

Traditional kilns require a complex and costly supply chain for fuel. Electric kilns completely eliminate expenses related to fuel procurement, transportation, and on-site storage. They also remove the significant costs associated with managing stringent fuel-related safety protocols.

The Growing Impact of Carbon Pricing

In many regions, CO2 taxes and emissions trading schemes add a direct and growing cost to using fossil fuels. Because electric kilns produce no direct on-site emissions, they are immune to these carbon-related financial penalties, providing a crucial and predictable long-term cost advantage.

Designing for Lower Long-Term Maintenance

The inherent design of modern electric kilns translates directly into reduced maintenance burdens and lower associated costs over the life of the equipment.

Simplified Mechanical Structure

Electric kilns have a fundamentally simpler architecture. A system composed primarily of an electromagnetic heater, a control system, and the kiln body has far fewer potential points of failure than a fuel-fired system with complex burners, fuel lines, and exhaust flues. This streamlined design leads to a lower rate of malfunctions.

The Value of Intelligent Automation

These systems are typically equipped with advanced sensors and control systems that enable highly automated operation and real-time monitoring. This intelligent oversight allows for the immediate detection of potential issues, improving reliability, enhancing safety, and dramatically lowering the overall complexity and cost of maintenance.

Understanding the Trade-offs

To make a fully informed decision, it's critical to weigh the benefits against the potential challenges. No technology is without its trade-offs.

Higher Initial Capital Expenditure

The initial purchase and installation cost of an advanced electric rotary kiln can be higher than that of a conventional fuel-fired alternative. This requires a financial analysis that prioritizes long-term operational savings over short-term capital outlay.

Dependence on Grid Stability

An electric kiln's operation is entirely dependent on the reliability of the electrical grid. In regions with unstable power, this can pose a significant operational risk, potentially requiring investment in backup power solutions.

Electricity Price Volatility

While electric kilns avoid the volatility of fossil fuel markets, they are subject to the pricing structure of their regional electricity provider. The cost per kilowatt-hour can fluctuate and may be high in certain areas, impacting overall operational expenditure.

Making the Right Choice for Your Operation

The decision to invest in an electric rotary kiln should be guided by your specific strategic and financial priorities.

- If your primary focus is minimizing upfront capital cost: A traditional fuel-fired kiln may still appear more attractive, but be sure to model the long-term impact of fuel, maintenance, and carbon costs.

- If your primary focus is lowering total cost of ownership (TCO): An electric rotary kiln is a compelling option, offering substantial savings through superior efficiency, reduced maintenance, and immunity to carbon taxes.

- If your primary focus is process control and predictability: The advanced automation of electric kilns delivers unmatched precision and reliability, though you must first confirm the stability of your local power grid.

Ultimately, evaluating an electric rotary kiln requires shifting your analysis from simply comparing fuel prices to assessing the entire lifecycle cost and efficiency of the system.

Summary Table:

| Key Economic Benefit | Why It Matters |

|---|---|

| Superior Thermal Efficiency | Direct heat transfer reduces total energy consumption and costs. |

| Eliminates Fuel Overhead | No costs for fuel procurement, storage, or safety protocols. |

| Immunity to Carbon Taxes | Avoids direct financial penalties from CO2 emissions pricing. |

| Lower Long-Term Maintenance | Simplified design and intelligent automation reduce repair costs. |

Ready to enhance your operation's efficiency and profitability?

Choosing the right thermal processing equipment is critical to your bottom line. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Our team can help you analyze if an electric rotary kiln is the right investment to lower your total cost of ownership. Contact us today for a personalized consultation and see how we can build a solution for you.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems