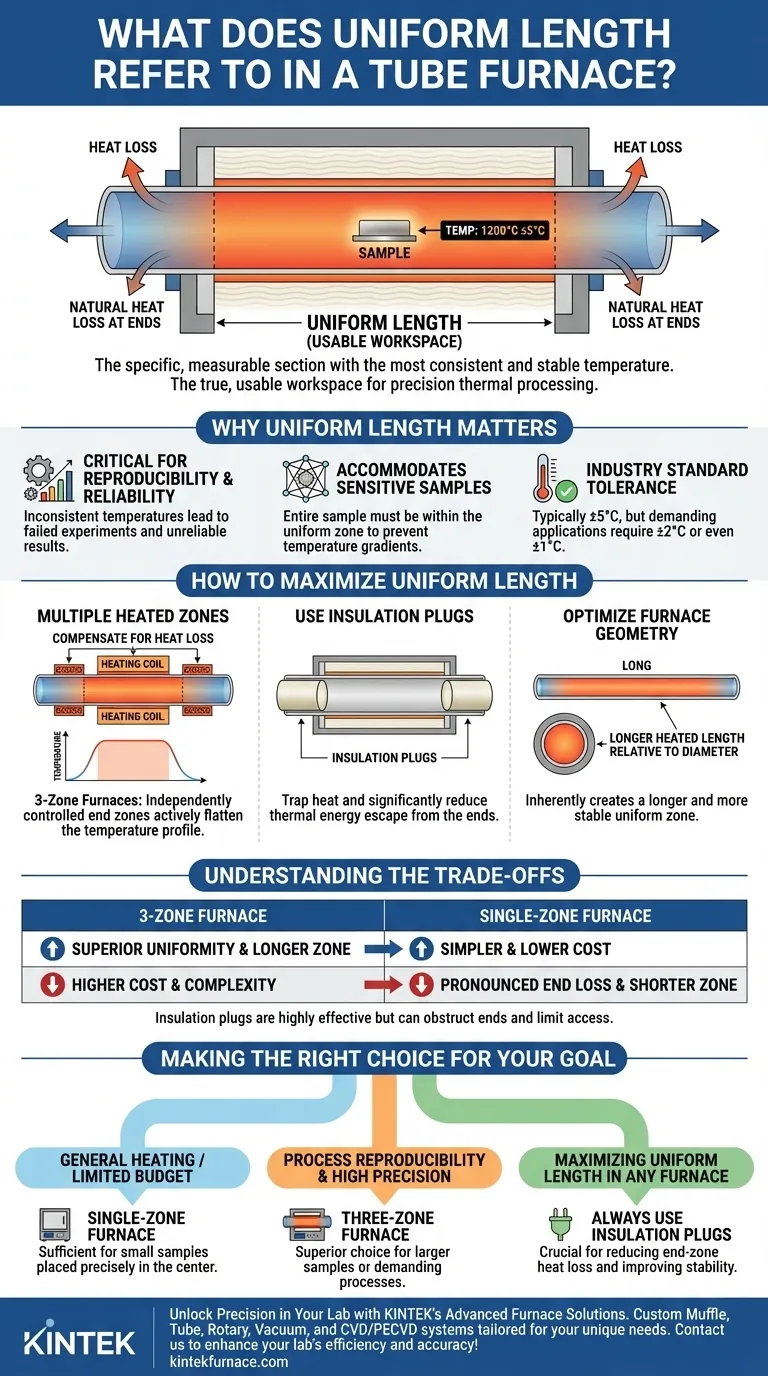

In a tube furnace, "uniform length" refers to the specific, measurable section within the heated chamber where the temperature is most consistent and stable. This zone, often specified with a tolerance such as ±5°C, represents the true, usable workspace for any process that requires precise thermal control.

The uniform length is the effective working area of your furnace. A longer, more stable uniform zone is not just a feature—it is the primary factor that determines the reliability and reproducibility of your thermal processing results.

Why Uniform Length Is a Critical Specification

The Problem of Natural Heat Loss

A tube furnace is fundamentally a hollow cylinder, and heat naturally escapes from its open ends. This unavoidable heat loss creates a temperature gradient along the length of the tube.

The center of the furnace will be at the setpoint temperature, but the temperature will inevitably drop off as you move toward the ends.

Defining the "Usable" Zone

The uniform length is the region where this temperature drop-off is minimal and within an acceptable tolerance. For any sensitive process, your sample must be placed entirely within this zone.

Placing a sample outside this area means different parts of it will experience different temperatures, leading to inconsistent results, failed experiments, and unreliable material production.

The Industry Standard for Uniformity

A common specification for a standard tube furnace is a uniformity of ±5°C over a defined central length.

However, more demanding applications, such as crystal growth or semiconductor research, may require much tighter tolerances, like ±2°C or even ±1°C.

How to Maximize Uniform Length

Achieving a long and stable uniform zone requires specific design features that actively combat the natural heat loss at the furnace ends.

The Impact of Multiple Heated Zones

A single-zone furnace has one set of heating elements and a single controller. It will always have a pronounced temperature drop-off at the ends.

A three-zone furnace, by contrast, has a main center zone and two smaller, independently controlled end zones. By setting the end zones to a slightly higher temperature, you can directly compensate for heat loss. This actively flattens the temperature profile and significantly extends the uniform length.

The Role of Insulation Plugs

Insulation plugs are high-temperature-resistant ceramic fiber cylinders placed inside the process tube, just outside the heated zone.

They act as physical barriers that trap heat, dramatically reducing the amount of thermal energy that escapes from the ends. Using them is one of the most effective ways to improve temperature uniformity in any tube furnace.

Furnace Geometry

The physical design of the furnace also plays a role. As a general rule, a furnace with a longer heated length relative to its tube diameter will inherently have a longer and more stable uniform zone.

Understanding the Trade-offs

Optimizing for uniform length involves clear engineering and budget trade-offs that you must consider.

Cost vs. Performance

A three-zone furnace provides far superior temperature uniformity and a longer effective working zone. However, its multiple controllers and more complex wiring make it significantly more expensive than a comparable single-zone model.

Simplicity vs. Control

While powerful, a three-zone furnace requires more user input. You must properly program all three controllers to create the desired flat profile, which adds a layer of operational complexity. A single-zone furnace is simpler to operate but offers no ability to correct for end losses.

Insulation vs. Access

Insulation plugs are highly effective but can obstruct the ends of the process tube. This can make it more difficult to load and unload samples or to establish a controlled gas atmosphere throughout the entire tube.

Making the Right Choice for Your Goal

Your application's requirements should dictate your choice of furnace configuration.

- If your primary focus is general heating or you're on a limited budget: A single-zone furnace is often sufficient, provided your sample is small and can be placed precisely in the center of the heated zone.

- If your primary focus is process reproducibility and high precision: A three-zone furnace is the superior choice, as it gives you direct control to extend and flatten the temperature profile for larger samples or more demanding processes.

- If your primary focus is maximizing the uniform length in any furnace: Always use insulation plugs to significantly reduce end-zone heat loss and improve the stability of your working area.

Ultimately, understanding uniform length empowers you to select the right tool and configure it correctly to ensure your results are both accurate and repeatable.

Summary Table:

| Feature | Description |

|---|---|

| Uniform Length | Zone in the furnace with consistent temperature, e.g., ±5°C tolerance |

| Key Factors | Multiple heated zones, insulation plugs, furnace geometry |

| Applications | Crystal growth, semiconductor research, general heating |

| Trade-offs | Cost vs. performance, simplicity vs. control, insulation vs. access |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Struggling with inconsistent thermal processing? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs.

Whether you're in materials science, semiconductor research, or general heating applications, we help you achieve reliable, reproducible results with optimized uniform length and precise temperature control. Don't let heat loss compromise your experiments—contact us today to discuss how our furnaces can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety