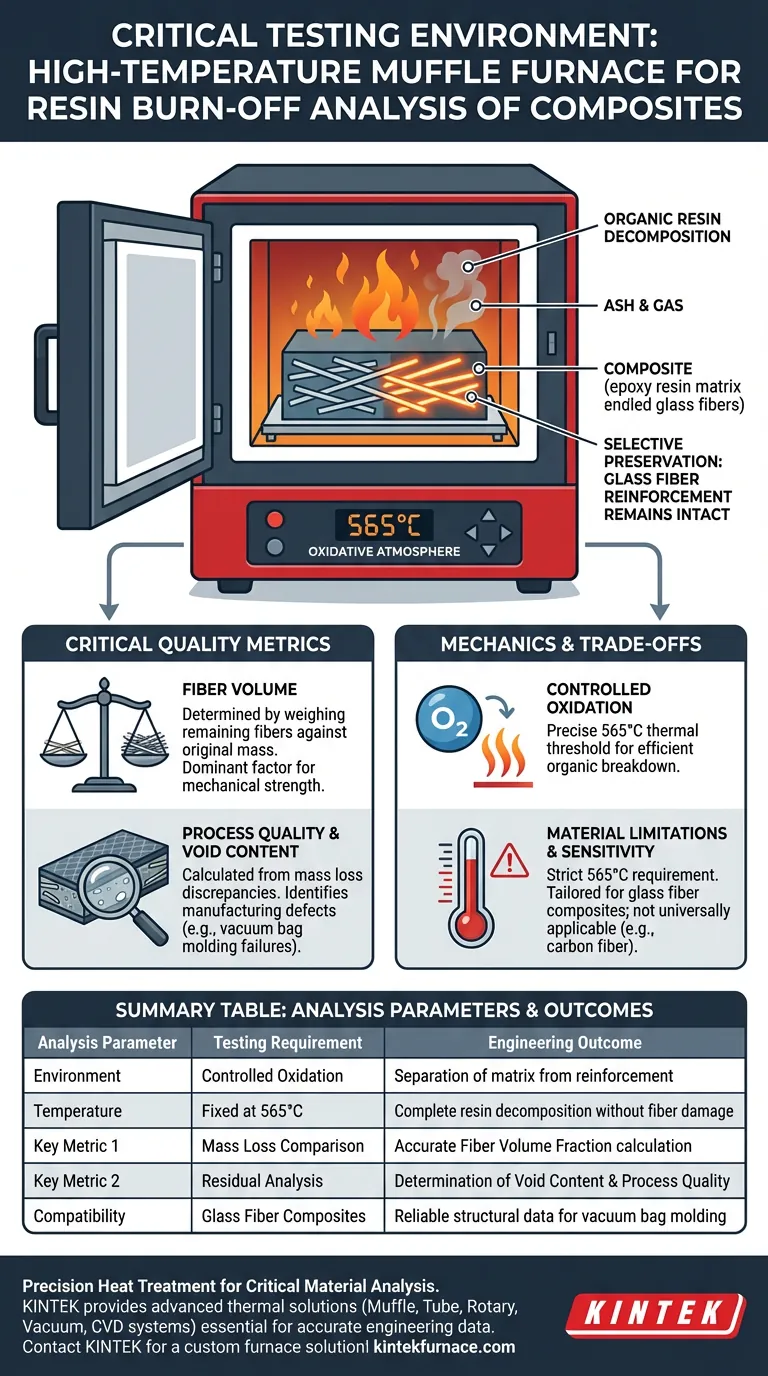

A high-temperature muffle furnace provides a strictly controlled oxidative environment specifically calibrated to separate the components of composite materials. By maintaining a precise, constant temperature of approximately 565°C, the furnace facilitates the total decomposition and removal of the epoxy resin matrix while preserving the structural integrity of the glass fiber reinforcement.

The core value of this environment is its ability to isolate the reinforcement from the matrix. By comparing the sample mass before and after the burn-off, technicians can accurately calculate void content and fiber volume fraction—the definitive metrics for evaluating the quality of the vacuum bag molding process.

The Mechanics of Resin Decomposition

Controlled Oxidation

The muffle furnace does not simply heat the material; it creates an oxidative atmosphere at a specific thermal threshold.

At approximately 565°C, the organic compounds within the epoxy resin break down efficiently.

This temperature is critical because it ensures the complete removal of organic substances, similar to how environmental samples are treated to remove pollutants, but applied here for structural analysis.

Selective Preservation

The testing environment is designed for selectivity.

While the heat is sufficient to turn the resin matrix into ash and gas, it is carefully capped to prevent damage to the glass fiber reinforcement.

The fibers remain intact, allowing them to be weighed and analyzed in isolation after the process is complete.

Critical Quality Metrics

Determining Fiber Volume Fraction

The primary output of this analysis is the fiber volume fraction.

By measuring the mass of the remaining glass fibers against the original sample mass, engineers determine how much of the composite is actual reinforcement versus binder.

This ratio is the dominant factor in the mechanical strength and stiffness of the final part.

Evaluating Process Quality

The data derived from the muffle furnace highlights the effectiveness of the manufacturing technique, specifically vacuum bag molding.

Discrepancies in mass loss allow technicians to calculate void content—tiny air pockets trapped in the material.

High void content usually indicates a failure in the molding process, such as insufficient pressure or poor resin flow.

Understanding the Trade-offs

Temperature Sensitivity

The strict control of the temperature is not merely a suggestion; it is a rigid requirement.

If the temperature drops significantly below 565°C, the resin may not burn off completely, leading to artificially high mass readings and incorrect fiber volume calculations.

Conversely, excessive temperatures could potentially degrade the glass fibers or alter their mass, rendering the data invalid.

Material Limitations

This specific oxidative environment is tailored for glass fiber composites.

It relies on the fact that glass withstands temperatures that destroy epoxy.

This method cannot be blindly applied to all composites (such as carbon fiber) without adjusting the atmosphere or temperature, as the reinforcement itself might oxidize and burn away.

Making the Right Choice for Your Goal

To utilize the muffle furnace effectively for your specific analysis, consider these strategic priorities:

- If your primary focus is Structural Analysis: Prioritize the accuracy of the fiber volume fraction, as this directly correlates to the theoretical strength of the component.

- If your primary focus is Manufacturing Quality Control: Concentrate on the void content calculation to identify process defects in the vacuum bag molding stage.

The muffle furnace transforms a complex composite into measurable constituents, turning raw material into actionable engineering data.

Summary Table:

| Analysis Parameter | Testing Requirement | Engineering Outcome |

|---|---|---|

| Environment | Controlled Oxidation | Separation of matrix from reinforcement |

| Temperature | Fixed at 565°C | Complete resin decomposition without fiber damage |

| Key Metric 1 | Mass Loss Comparison | Accurate Fiber Volume Fraction calculation |

| Key Metric 2 | Residual Analysis | Determination of Void Content & Process Quality |

| Compatibility | Glass Fiber Composites | Reliable structural data for vacuum bag molding |

Precision Heat Treatment for Critical Material Analysis

Unlock the full potential of your composite testing with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific laboratory requirements.

Whether you need to determine fiber volume fraction or minimize void content, our equipment provides the thermal stability and atmospheric control essential for accurate engineering data. Empower your quality control process today—Contact KINTEK for a custom furnace solution!

Visual Guide

References

- Nur Hafzareen Md Hanafiah, Mark Ovinis. Significant Effect of Vacuum Bagging Processing on Inter-Laminar Shear Strength and Voids of Composite in Oven Cure. DOI: 10.37934/araset.37.1.6981

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the heating process work in a muffle furnace? Discover Clean, Uniform Heating for Your Lab

- Why are muffle furnaces used to determine moisture, ash, and volatile content in pharmaceutical materials? Essential for Precise Quality Control

- Why is a laboratory box resistance furnace essential for simulating long-term high-temperature oxidation exposure?

- What role does a high-performance muffle furnace play in the synthesis of Co3O4 nanoparticles from precursor gels?

- What is a box furnace and what are its common uses? Discover Versatile High-Temperature Solutions

- What role does a laboratory muffle furnace play in the fluorination roasting stage of NdFeB waste recovery?

- Why was the muffle furnace initially developed? To Ensure Purity in High-Temperature Processing

- How does a muffle furnace facilitate the slow pyrolysis process? Optimize Biochar Production from Organic Waste