At its core, a box furnace is a high-temperature oven designed for precise thermal processing. Also known as a muffle furnace, this rectangular or square-shaped equipment is a staple in laboratories and industrial settings where materials require heating to very high temperatures in a controlled, stable environment. Its common applications range from heat-treating metals and sintering ceramics to conducting material analysis like burn-off tests.

The true value of a box furnace is not just its ability to generate extreme heat, but its capacity to provide a stable, precisely controlled thermal environment for stationary items. This makes it the definitive tool for batch-based thermal processing.

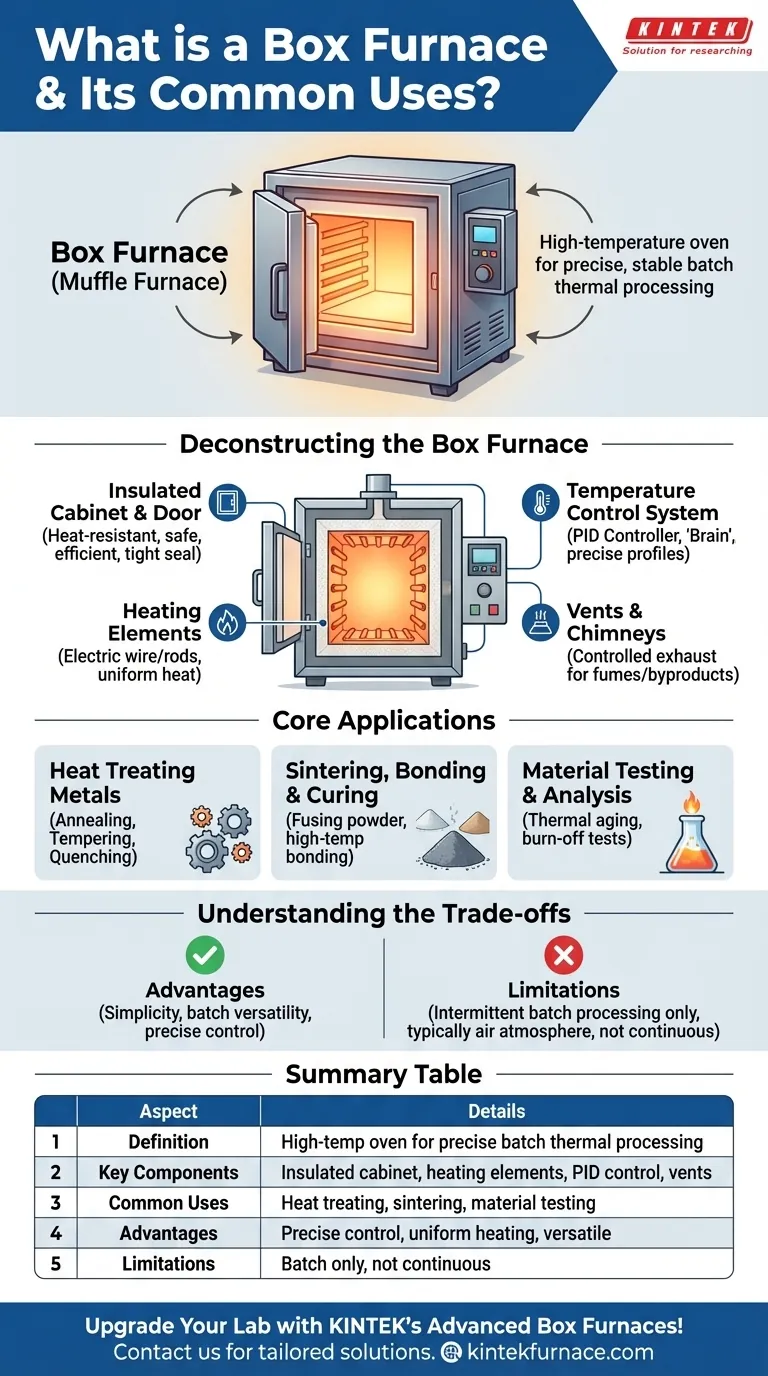

Deconstructing the Box Furnace: Key Components

A box furnace's effectiveness comes from the synergy of a few critical components. Understanding them reveals how it achieves such precise results.

The Insulated Cabinet and Door

The main body, or "box," is constructed from high-temperature, heat-resistant materials. This heavy insulation ensures two things: the furnace reaches and maintains its target temperature efficiently, and the exterior remains at a safe temperature for operators.

Materials are loaded and unloaded through a single, heavily insulated door, which seals tightly to prevent heat loss during operation.

The Heating Elements

The heat itself is typically generated by electric heating elements, such as high-resistance wire or silicon carbide rods. These are strategically placed within the furnace chamber to provide stable and uniform heating, eliminating hot spots and ensuring the entire workpiece is processed evenly.

The Temperature Control System

This is the "brain" of the furnace. A modern box furnace includes an automated temperature control system, often a digital PID (Proportional-Integral-Derivative) controller. It allows the user to program specific heating rates, soaking times at target temperatures, and cooling profiles, ensuring processes are repeatable and precise.

Vents and Chimneys

Most box furnaces include a controllable vent or chimney, often at the back. This is crucial for applications like burn-off or debinding, where fumes and combustion byproducts must be safely exhausted from the chamber.

Core Applications: From Lab Analysis to Industrial Production

The box furnace is not a single-purpose tool. Its versatility makes it essential across a wide range of fields.

Heat Treating Metals

This is a primary application, used to alter the physical and mechanical properties of metals. Processes include annealing (softening), tempering (increasing toughness), and quenching (hardening) small steel parts or other metallic components.

Sintering, Bonding, and Curing

In materials science and manufacturing, a box furnace is used for sintering, a process that fuses powdered materials like ceramics or metals into a solid mass using heat. It's also used for high-temperature bonding of components and for curing materials like industrial enamels.

Material Testing and Analysis

Laboratories rely on box furnaces for a variety of analytical tests. These include thermal aging to see how materials perform over time at high temperatures and asphalt binder analysis, where all organic material is burned off to measure the remaining aggregate.

Understanding the Trade-offs

While incredibly useful, the box furnace is not the solution for every heating application. Objectivity requires understanding its specific strengths and limitations.

The Advantage: Simplicity and Batch Versatility

The box furnace is valued for its simple operation and convenient maintenance. Its design makes it an ideal general-purpose tool for labs or workshops that handle a variety of different processes and materials on a smaller, non-continuous scale.

The Limitation: Intermittent Batch Processing

A box furnace is an intermittent or batch furnace. Materials are loaded, heated while stationary, and then unloaded. This makes it unsuitable for high-volume, continuous production lines where a conveyor or tunnel furnace would be more efficient.

The Consideration: Atmosphere Control

Standard box furnaces operate with an air atmosphere. While vents allow for the removal of byproducts, they do not provide the tightly controlled inert or vacuum atmospheres required for processing highly reactive metals or sensitive electronic components. For those applications, a specialized vacuum or retort furnace is necessary.

Making the Right Choice for Your Goal

Selecting the correct thermal equipment depends entirely on your process requirements.

- If your primary focus is versatile lab research or small-batch production: A box furnace offers the ideal balance of precision, high temperature, and operational simplicity for various tasks.

- If your primary focus is analyzing material composition via burn-off: A box furnace with a reliable, controllable vent is the standard and necessary tool for the job.

- If your primary focus is high-volume, continuous manufacturing: You should investigate conveyor or continuous belt furnaces, as a box furnace's batch nature will create a production bottleneck.

Ultimately, the box furnace is a foundational piece of equipment valued for its reliable and precise execution of high-temperature batch processes.

Summary Table:

| Aspect | Details |

|---|---|

| Definition | High-temperature oven for precise thermal processing in batch mode |

| Key Components | Insulated cabinet, heating elements, temperature control system, vents/chimneys |

| Common Uses | Heat treating metals, sintering ceramics, material testing (e.g., burn-off) |

| Advantages | Precise temperature control, uniform heating, versatile for various materials |

| Limitations | Batch processing only, not for continuous production or inert atmospheres |

Upgrade Your Lab with KINTEK's Advanced Box Furnaces!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in research, material testing, or small-batch production, our box furnaces deliver reliable performance and precise control to enhance your processes.

Contact us today to discuss how our tailored solutions can drive your success!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation