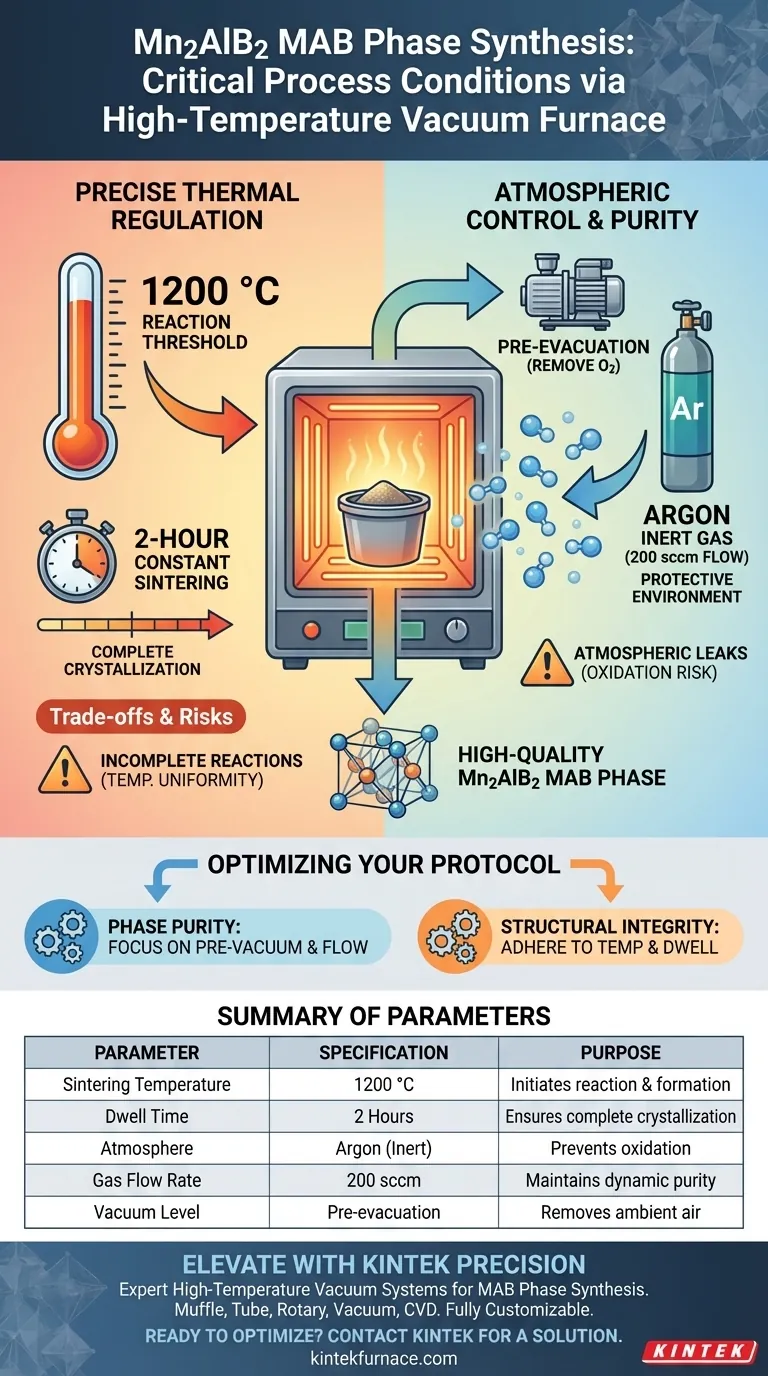

A high-temperature vacuum furnace is the critical enabler for synthesizing the Mn2AlB2 MAB phase because it simultaneously manages extreme heat and atmospheric purity. Specifically, it maintains a precise sintering temperature of 1200 °C while establishing a protected environment using a 200 sccm argon flow to prevent material degradation.

Synthesizing high-quality Mn2AlB2 requires a delicate balance of thermal energy and chemical isolation. The furnace's ability to sustain 1200 °C under a controlled inert gas flow ensures that precursors react completely to form the correct crystal structure without succumbing to oxidation.

Precise Thermal Regulation

Reaching the Reaction Threshold

To synthesize Mn2AlB2, the furnace must provide rigorous temperature control centered at 1200 °C. This specific thermal energy level is required to initiate the solid-state reactions between the precursor materials.

Ensuring Complete Crystallization

Reaching peak temperature is insufficient on its own; the duration of heat exposure is equally critical. The process requires a 2-hour constant temperature sintering period.

This dwell time allows the chemical reactions to reach completion. It ensures the material fully crystallizes into the characteristic layered structure that defines the MAB phase.

Atmospheric Control and Purity

Eliminating Oxygen

At 1200 °C, metal components are highly susceptible to rapid oxidation. The vacuum furnace mitigates this by pre-evacuating the chamber to remove ambient air before heating begins.

Maintaining an Inert Environment

Once evacuated, the system introduces an inert gas, specifically argon, to create a protective atmosphere. This prevents oxygen from interacting with the metal, effectively blocking the formation of unwanted oxides and impurities.

Managing Gas Flow

The process relies on a dynamic atmosphere rather than a static one. A continuous argon flow of 200 sccm (standard cubic centimeters per minute) is maintained throughout the process.

This flow helps stabilize the environment. It ensures that the atmosphere remains consistently inert surrounding the sample during the critical reaction window.

Understanding the Trade-offs

The Risk of Incomplete Reactions

While the 2-hour window is standard, deviation in temperature uniformity can lead to issues. If the furnace fails to hold 1200 °C consistently across the entire sample, you risk incomplete chemical reactions and poor structural formation.

Sensitivity to Atmospheric Leaks

The reliance on a vacuum-purge and argon-fill cycle creates a single point of failure. Even a minor breach in the chamber's integrity will allow oxygen ingress, instantly compromising the purity of the Mn2AlB2 phase despite correct temperature settings.

Optimizing Your Synthesis Protocol

To ensure successful synthesis of Mn2AlB2, align your process parameters with your specific quality goals:

- If your primary focus is phase purity: Prioritize the pre-evacuation step and verify the 200 sccm argon flow to guarantee a strictly oxygen-free environment.

- If your primary focus is structural integrity: strictly adhere to the 1200 °C setpoint and the full 2-hour dwell time to maximize crystallization.

Precision in these environmental variables is the defining factor between a failed experiment and a high-quality MAB phase material.

Summary Table:

| Parameter | Specification | Purpose in Mn2AlB2 Synthesis |

|---|---|---|

| Sintering Temperature | 1200 °C | Initiates solid-state reaction and crystal formation |

| Dwell Time | 2 Hours | Ensures complete chemical reaction and crystallization |

| Atmosphere | Argon (Inert) | Prevents oxidation of metallic precursors |

| Gas Flow Rate | 200 sccm | Maintains dynamic purity and stabilizes the environment |

| Vacuum Level | Pre-evacuation | Removes oxygen and ambient air before heating |

Elevate Your MAB Phase Synthesis with KINTEK Precision

Achieving the delicate balance of 1200°C thermal stability and atmospheric purity is critical for high-quality Mn2AlB2 production. KINTEK provides industry-leading high-temperature vacuum and atmosphere-controlled systems designed to eliminate oxidation and ensure structural integrity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique lab requirements. Don't compromise on phase purity—partner with the experts in thermal processing.

Ready to optimize your synthesis protocol? Contact KINTEK today for a customized solution.

Visual Guide

References

- Fatma Nur Tuzluca Yesilbag, Ahmad Hüseyin. The effect of Aluminum (Al) ratio on the synthesis of the laminated Mn2AlB2 MAB Phase. DOI: 10.18185/erzifbed.1514470

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the characteristics of vacuum heat treatment? Unlock Superior Material Performance and Control

- What is the purpose of transferring high-temperature glass to a preheated annealing furnace? Ensuring Sample Integrity

- What are common insulation materials used in vacuum furnaces? Optimize Heat Control for Your Lab

- How does a precise temperature control system prevent Rubidium Chloride loss? Optimize Vacuum Distillation Yield

- How does vacuum tempering contribute to energy efficiency? Superior furnace design slashes thermal waste and cuts costs.

- How does an ultra-high temperature graphitization furnace enhance thermal conductivity? | KINTEK Advanced Solutions

- How does a vacuum annealing furnace facilitate the purification of carbon nanofibers (CNF)? Achieve Ultra-High Purity

- What are the five main components of a vacuum melting furnace? Essential for High-Purity Metal Production