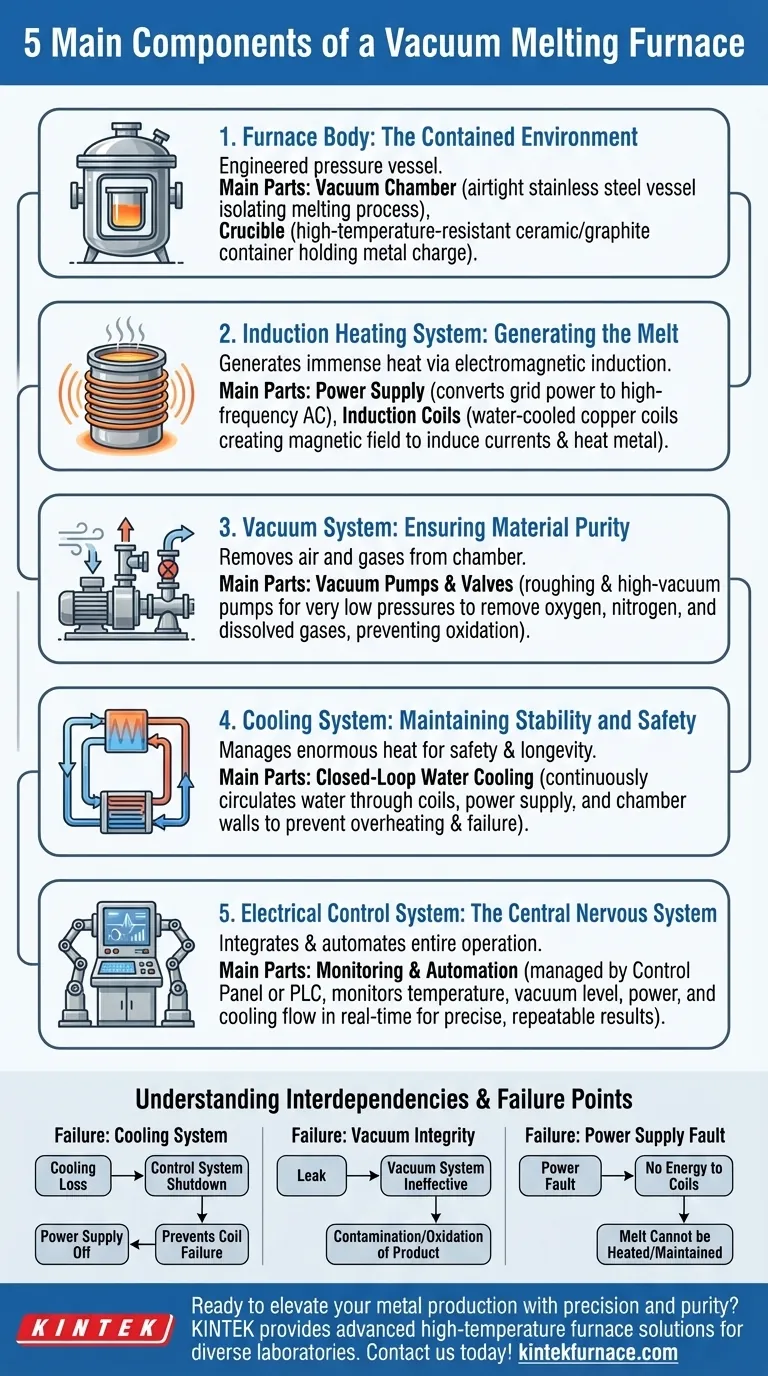

At its core, a vacuum melting furnace is an integrated system with five primary components working in unison. These are the furnace body, the induction heating system, the vacuum system, the cooling system, and the electrical control system. Together, these components create a highly controlled environment to melt metals and produce high-purity alloys by preventing oxidation and removing gaseous impurities.

Understanding these components is not about memorizing a list of parts. It's about recognizing how a furnace creates a contained environment (vacuum chamber), applies precise energy (heating), removes contaminants (vacuum pumps), and manages extreme temperatures (cooling) under the direction of a central brain (control system).

The Furnace Body: The Contained Environment

The furnace body is the primary physical structure that contains the entire melting process. It's more than just a box; it's a precisely engineered pressure vessel.

The Vacuum Chamber

The main component of the body is the vacuum chamber, an airtight vessel typically made of stainless steel. Its fundamental job is to isolate the melting process from the outside atmosphere, allowing a deep vacuum to be created and maintained.

The Crucible

Inside the chamber sits the crucible, a high-temperature-resistant container that holds the metal charge. The material of the crucible, often ceramic or graphite, is chosen carefully to avoid reacting with the molten metal it contains.

The Induction Heating System: Generating the Melt

This system is responsible for generating the immense heat required for melting, using the principles of electromagnetic induction. It consists of two key parts.

The Power Supply

The medium-frequency power supply is the heart of the heating system. It takes standard electrical grid power and converts it into high-frequency alternating current. The frequency is critical for determining the efficiency and stirring effect of the melt.

The Induction Coils

This high-frequency current is fed into water-cooled copper induction coils that wrap around the crucible (but do not touch it). The current creates a powerful, rapidly changing magnetic field, which in turn induces massive electrical currents within the metal charge, heating it rapidly until it melts.

The Vacuum System: Ensuring Material Purity

The vacuum system is what separates this process from standard atmospheric melting. Its purpose is to remove air and other gases from the chamber before and during the melt.

Pumps and Valves

This system consists of a series of vacuum pumps and valves. A typical setup uses a roughing pump to remove the bulk of the air, followed by a high-vacuum pump (like a diffusion or turbomolecular pump) to achieve the very low pressures needed for high-purity melts. This process removes oxygen and nitrogen, preventing oxidation, and also pulls dissolved gases out of the molten metal itself.

The Cooling System: Maintaining Stability and Safety

A vacuum furnace generates enormous amounts of heat, and managing this thermal energy is critical for both safety and equipment longevity.

Closed-Loop Water Cooling

A closed-loop water cooling system continuously circulates water through critical components. This includes the induction coils, the power supply, and even the walls of the vacuum chamber itself. Without constant cooling, the copper coils would quickly overheat and fail, and the chamber seals could be compromised.

The Electrical Control System: The Central Nervous System

The control system is the brain of the entire operation, integrating and automating the other four systems for precise, repeatable results.

Monitoring and Automation

This system, often managed from a central control panel or PLC (Programmable Logic Controller), monitors all critical parameters in real-time. This includes temperature, vacuum level, power output, and cooling water flow. It allows operators to execute precise melting recipes and provides alarms and safety shutdowns if any parameter goes outside of its safe operating range.

Understanding System Interdependencies

No single component works in isolation. A failure in one system can have a cascading effect on the entire process, highlighting the importance of understanding how they are interconnected.

Failure Point: Cooling System

A loss of cooling water flow is one of the most critical failure modes. It will almost instantly cause the control system to shut down the power supply to prevent the catastrophic failure of the induction coils.

Failure Point: Vacuum Integrity

A leak in the furnace body or its seals prevents the vacuum system from reaching the required pressure. This compromises the entire purpose of the furnace, leading to contamination and oxidation of the final product.

Failure Point: Power Supply Fault

A fault in the power supply means no energy can be delivered to the induction coils. The melt cannot be heated or maintained, rendering the furnace inoperable until the power electronics are repaired.

Making the Right Choice for Your Goal

When evaluating or operating a vacuum furnace, your specific goal dictates which system's performance is most critical.

- If your primary focus is alloy purity: Your most critical component is the high-performance vacuum system, capable of achieving and holding deep vacuums to remove all gaseous impurities.

- If your primary focus is throughput and speed: Your most critical components are the induction heating system for rapid melting and the cooling system to enable fast cycle times between batches.

- If your primary focus is process consistency: Your most critical component is a sophisticated electrical control system that provides precise automation and data logging for perfect repeatability.

Ultimately, a vacuum furnace is a balanced machine where each part must function perfectly for the entire system to achieve its purpose.

Summary Table:

| Component | Key Function | Key Parts |

|---|---|---|

| Furnace Body | Contains the melting process and maintains vacuum | Vacuum chamber, crucible |

| Induction Heating System | Generates heat for melting via electromagnetic induction | Power supply, induction coils |

| Vacuum System | Removes air and gases to prevent oxidation and impurities | Vacuum pumps, valves |

| Cooling System | Manages heat to ensure safety and equipment longevity | Closed-loop water cooling |

| Electrical Control System | Monitors and automates operations for precision | Control panel, PLC |

Ready to elevate your metal production with precision and purity? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our vacuum melting furnaces can deliver high-purity alloys and consistent results for your specific goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification