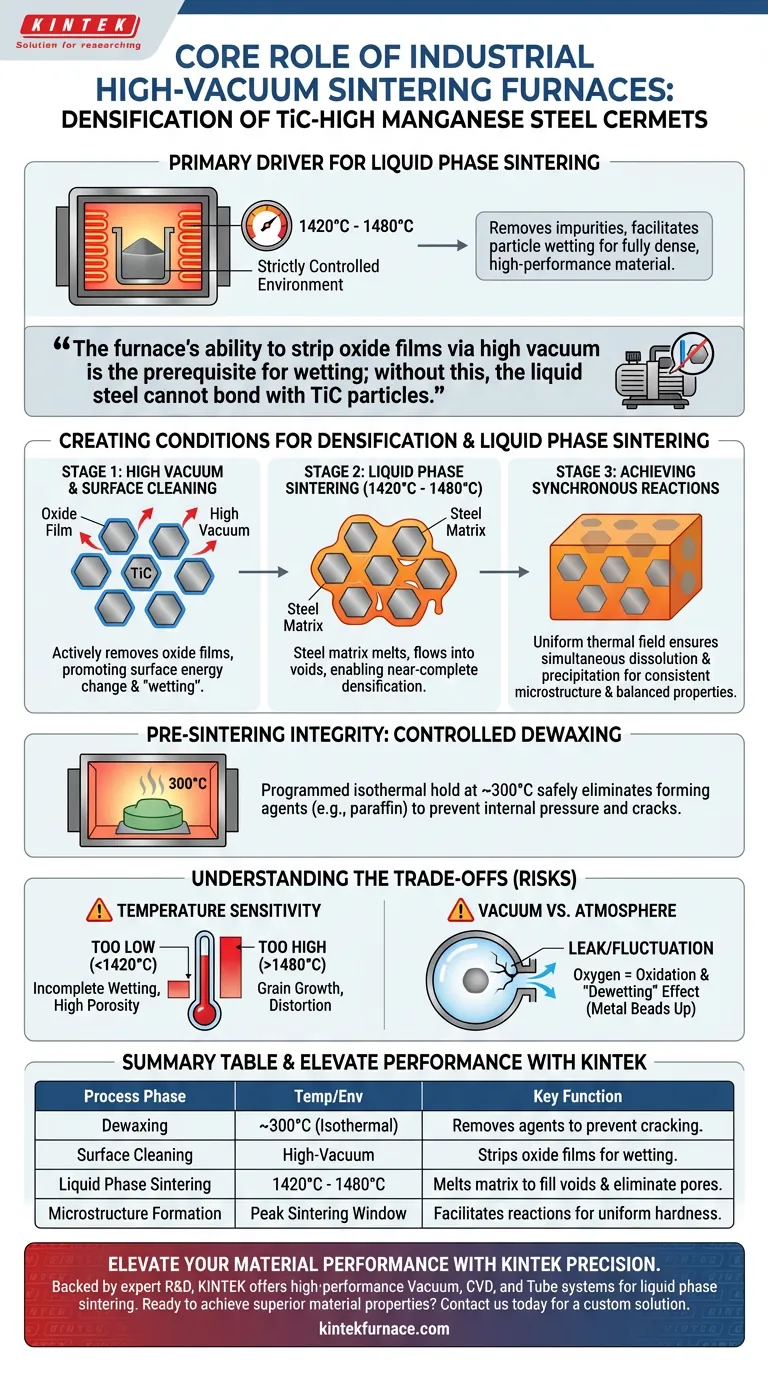

An industrial high-vacuum sintering furnace functions as the primary driver for liquid phase sintering in TiC-high manganese steel cermets. It establishes a strictly controlled environment, specifically between 1420°C and 1480°C, to ensure the steel matrix enters a liquid state while strictly managing atmospheric conditions. This process removes impurities and facilitates the particle wetting required to transform loose powder into a fully dense, high-performance material.

The furnace’s ability to strip oxide films via high vacuum is the prerequisite for wetting; without this, the liquid steel cannot bond with TiC particles, rendering densification impossible regardless of temperature.

Creating the Conditions for Densification

The Critical Role of High Vacuum

The most fundamental barrier to sintering cermets is the presence of oxide films on the powder surfaces. The high-vacuum environment actively removes these oxides, cleaning the surface of the TiC particles.

Once cleaned, the surface energy changes, promoting "wetting." This allows the liquid manganese steel matrix to spread evenly over and bond with the hard ceramic particles.

Facilitating Liquid Phase Sintering

The furnace must maintain a precise temperature range of 1420°C to 1480°C. Within this window, the steel matrix melts, triggering liquid phase sintering.

Because the vacuum has prepared the surfaces, the liquid metal flows into the voids between solid particles. This fills the pore spaces and results in near-complete densification of the material.

Achieving Synchronous Reactions

A uniform thermal field within the furnace ensures that dissolution and precipitation reactions occur simultaneously throughout the batch.

This uniformity is essential for developing a consistent microstructure. It leads to optimal mechanical properties, specifically balancing high hardness with impact toughness.

Pre-Sintering Integrity

Controlled Dewaxing

Before reaching peak sintering temperatures, the furnace plays a vital role in preserving the structural integrity of the "green body" (the pressed powder shape).

The process includes a programmed isothermal hold at 300°C. This step is designed to safely eliminate forming agents, such as paraffin, which were added during the pressing stage.

Preventing Structural Defects

Precise temperature control during this early phase is critical. It prevents the rapid volatilization of agents.

If these agents turn to gas too quickly, they generate internal pressure that causes cracks. Proper furnace control ensures these agents are removed without compromising the material structure.

Understanding the Trade-offs

Temperature Sensitivity

Operating outside the 1420°C to 1480°C window presents significant risks. Temperatures that are too low will result in incomplete wetting and high porosity.

Conversely, excessive temperatures can lead to grain growth or distortion of the cermet shape. The furnace's ability to hold this specific range is the difference between a usable part and scrap.

Vacuum vs. Atmosphere

While vacuum is essential for oxide removal, it must be maintained strictly. Any leak or fluctuation in vacuum pressure introduces oxygen, which instantly inhibits wetting.

A compromised vacuum environment leads to a "dewetting" effect, where the metal beads up rather than spreading, destroying the material's toughness.

Making the Right Choice for Your Goal

To maximize the utility of your sintering process, align your furnace parameters with your specific quality targets:

- If your primary focus is structural integrity: Prioritize the accuracy of the low-temperature stage, ensuring a stable 30-minute hold at 300°C to eliminate paraffin without inducing micro-cracks.

- If your primary focus is mechanical performance: Strict adherence to the 1420°C to 1480°C peak temperature range is required to ensure complete oxide removal and maximum density.

Ultimately, the furnace is not just a heat source, but a precision tool for surface chemistry modification and void elimination.

Summary Table:

| Process Phase | Temperature Range | Key Function |

|---|---|---|

| Dewaxing | ~300°C (Isothermal) | Removes paraffin/forming agents to prevent cracking. |

| Surface Cleaning | High-Vacuum Environment | Strips oxide films from TiC particles to enable wetting. |

| Liquid Phase Sintering | 1420°C - 1480°C | Melts the steel matrix to fill voids and eliminate pores. |

| Microstructure Formation | Peak Sintering Window | Facilitates dissolution/precipitation for uniform hardness. |

Elevate Your Material Performance with KINTEK Precision

Don't let oxide films or inconsistent thermal fields compromise your cermet production. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum, CVD, and Tube systems designed for the rigorous demands of liquid phase sintering.

Whether you need precise atmospheric control for TiC-steel composites or a customizable high-temperature solution for specialized lab needs, our furnaces ensure near-complete densification and optimal impact toughness.

Ready to achieve superior material properties? Contact us today for a custom solution.

Visual Guide

References

- Nyasha Matsanga, Willie Nheta. An Overview of Thermochemical Reduction Processes for Titanium Production. DOI: 10.3390/min15010017

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What temperature range can vacuum furnaces achieve? Unlock High-Temp Precision for Your Lab

- Why is a vacuum drying oven critical for moisture-sensitive batteries? Ensuring Stability in Potassium-Ion Systems

- How does a vacuum furnace ensure high-quality output? Achieve Superior Purity and Performance for Your Materials

- What temperature range can most vacuum furnace systems operate within? Discover the Capabilities for Your Process

- Why is a laboratory oven used for borated nanodiamond synthesis? Ensure Pure Chemical Surface Growth

- How does vacuum heat treatment enhance product quality? Achieve Superior Material Integrity and Performance

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What type of environment does a high vacuum furnace create? Achieve Purity and Precision in Heat Treatment