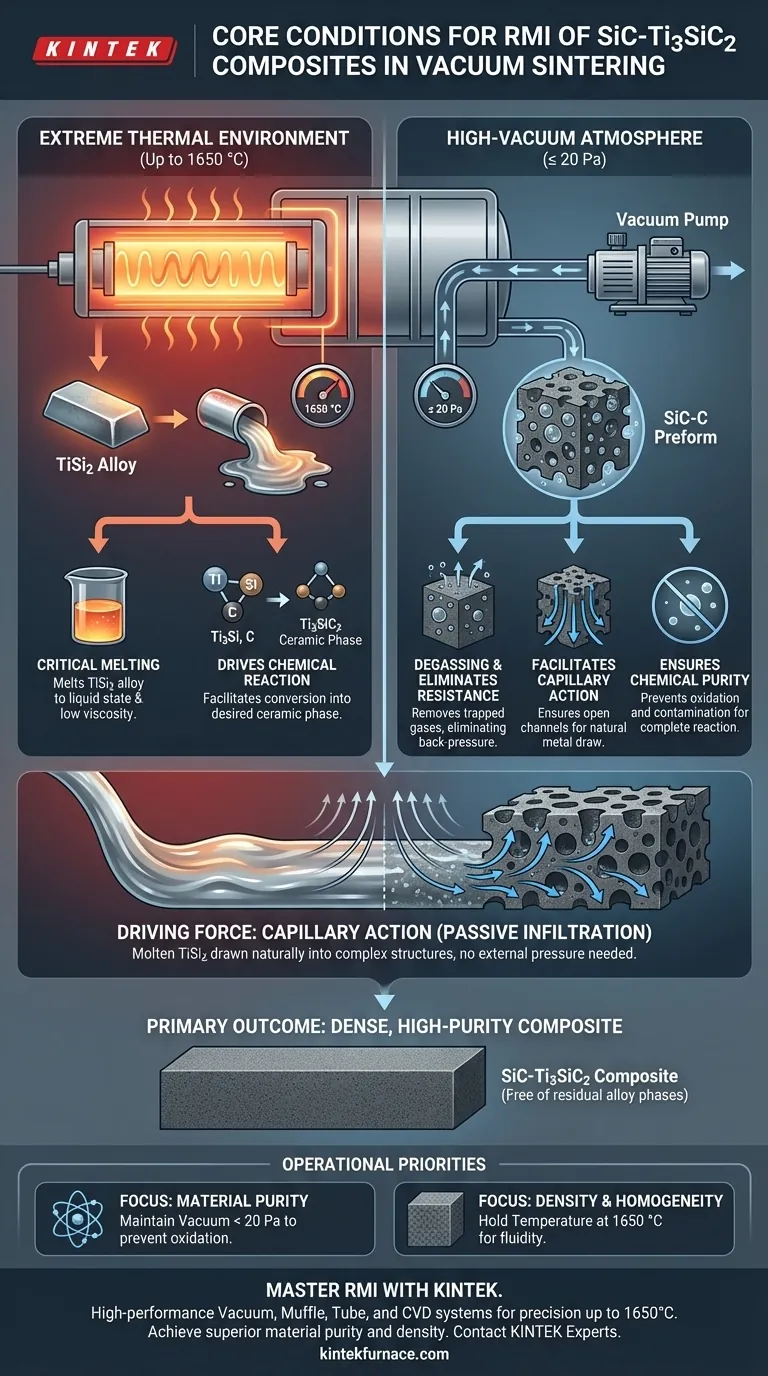

The core physical conditions provided by a vacuum sintering furnace for this specific process are an extreme thermal environment reaching 1650 °C and a high-vacuum atmosphere with pressures maintained at or below 20 Pa.

These specific parameters are engineered to induce the melting of the TiSi2 alloy, allowing it to penetrate the porous SiC-C preform solely through capillary forces rather than external mechanical pressure.

Core Takeaway Success in Reactive Melt Infiltration (RMI) relies on a precise synergy: extreme heat melts the reactive alloy, while a high vacuum "clears the path" by evacuating gases from pores. This combination allows the molten metal to infiltrate deeply and react completely with the carbon structure, yielding a high-purity composite free of residual alloy phases.

The Role of Extreme Thermal Energy

Reaching the Critical Melting Point

To initiate the infiltration process, the furnace must reach temperatures up to 1650 °C.

This extreme heat is necessary to fully melt the TiSi2 alloy. Only when the alloy is in a completely liquid state can it achieve the viscosity required to flow into the complex, microscopic structures of the preform.

Driving the Chemical Reaction

Beyond simple melting, this thermal energy drives the chemical kinetics of the process.

The high temperature facilitates the reaction between the molten metal and the carbon within the preform. This ensures the conversion of raw materials into the desired Ti3SiC2 ceramic phase rather than leaving unreacted precursors.

The Function of the Vacuum Environment

Eliminating Resistance to Infiltration

The furnace maintains a vacuum level not exceeding 20 Pa.

This low-pressure environment is critical for degassing. By evacuating air and volatile gases trapped within the pores of the preform, the vacuum removes the back-pressure that would otherwise resist the entry of the molten metal.

Facilitating Capillary Action

Because RMI relies on capillary forces rather than mechanical rams to move material, the pathway must be unobstructed.

The vacuum ensures that the pores act as open channels. This allows the molten TiSi2 to be drawn naturally and deeply into the SiC-C preform, resulting in a fully dense composite.

Ensuring Chemical Purity

A high-vacuum environment prevents contaminants from interfering with the delicate chemistry of the composite.

By removing oxygen and other atmospheric gases, the furnace prevents the oxidation of the metal melt and the carbon preform. This promotes a complete reaction, producing a high-purity composite devoid of unwanted residual alloy phases.

Understanding the Trade-offs

While the vacuum sintering RMI process is efficient for complex shapes, it presents specific challenges compared to other methods like hot pressing.

Reliance on Wetting Behavior

Because this process relies on capillary forces (passive infiltration) rather than mechanical pressure (active forcing), the wetting angle between the liquid metal and the preform is non-negotiable. If the vacuum quality degrades (pressure rises above 20 Pa), surface oxidation can occur, inhibiting wetting and leading to incomplete infiltration.

Temperature Sensitivity

The process requires a delicate thermal balance. Temperatures must be high enough (1650 °C) to ensure low viscosity for infiltration, but excessive temperatures can lead to aggressive reactions that degrade the structural integrity of the preform before infiltration is complete.

Making the Right Choice for Your Goal

To optimize the RMI process for SiC-Ti3SiC2 composites, focus on these operational priorities:

- If your primary focus is Material Purity: Rigorously maintain vacuum levels below 20 Pa to prevent oxidation and ensure no residual alloy phases remain in the final matrix.

- If your primary focus is Density and Homogeneity: Ensure the temperature profile holds steadily at 1650 °C to guarantee sufficient fluidity of the TiSi2 alloy for complete capillary infiltration.

Mastering the RMI process requires viewing the vacuum not just as a lack of air, but as an active tool that pulls the reactive metal into the core of your material.

Summary Table:

| Parameter | Specification | Functional Role in RMI Process |

|---|---|---|

| Sintering Temperature | Up to 1650 °C | Melts TiSi2 alloy & drives chemical kinetics for ceramic phase conversion |

| Vacuum Pressure | ≤ 20 Pa | Degasses pores to remove back-pressure; prevents oxidation of melt |

| Driving Force | Capillary Action | Enables passive infiltration of molten metal into complex preform shapes |

| Primary Outcome | Dense Composite | Produces high-purity SiC-Ti3SiC2 free of residual alloy phases |

Elevate Your Advanced Ceramic Manufacturing with KINTEK

Precision in Reactive Melt Infiltration (RMI) requires uncompromising control over thermal and atmospheric variables. At KINTEK, we empower researchers and industrial manufacturers with high-performance Vacuum, Muffle, Tube, and CVD systems designed to maintain stable environments up to 1650°C and ultra-low pressures.

Whether you are developing SiC-Ti3SiC2 composites or custom high-temp materials, our expert R&D and manufacturing teams provide fully customizable furnace solutions tailored to your unique specifications.

Ready to achieve superior material purity and density?

Contact KINTEK Experts Today to find the perfect thermal processing solution for your laboratory.

Visual Guide

References

- Mingjun Zhang, Bo Wang. Electromagnetic Interference Shielding Effectiveness of Pure SiC–Ti3SiC2 Composites Fabricated by Reactive Melt Infiltration. DOI: 10.3390/ma18010157

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How is furnace brazing used in research and development? Unlock Precision Joining for Material Innovation

- Why is vacuum degassing equipment utilized in the preparation of low-alloy fire-resistant steel? | KINTEK Solutions

- How do thermal imagers and hybrid AI models facilitate leak detection? 92% Accuracy in Industrial Furnaces

- How does a Grain Boundary Diffusion (GBD) heat treatment furnace improve the performance of high-grade magnets?

- What industries benefit from using vacuum furnaces? Achieve Purity and Precision in High-Stakes Sectors

- What role do vacuum annealing furnaces play in optical material processing? Enhance Clarity and Performance for Your Optics

- What process environment does a pit-type resistance furnace provide? Expert Insights for Al-Cu-Mg-Ag Alloy Melting

- What are the disadvantages of graphite furnace? High Cost, Slow Speed, and Complexity