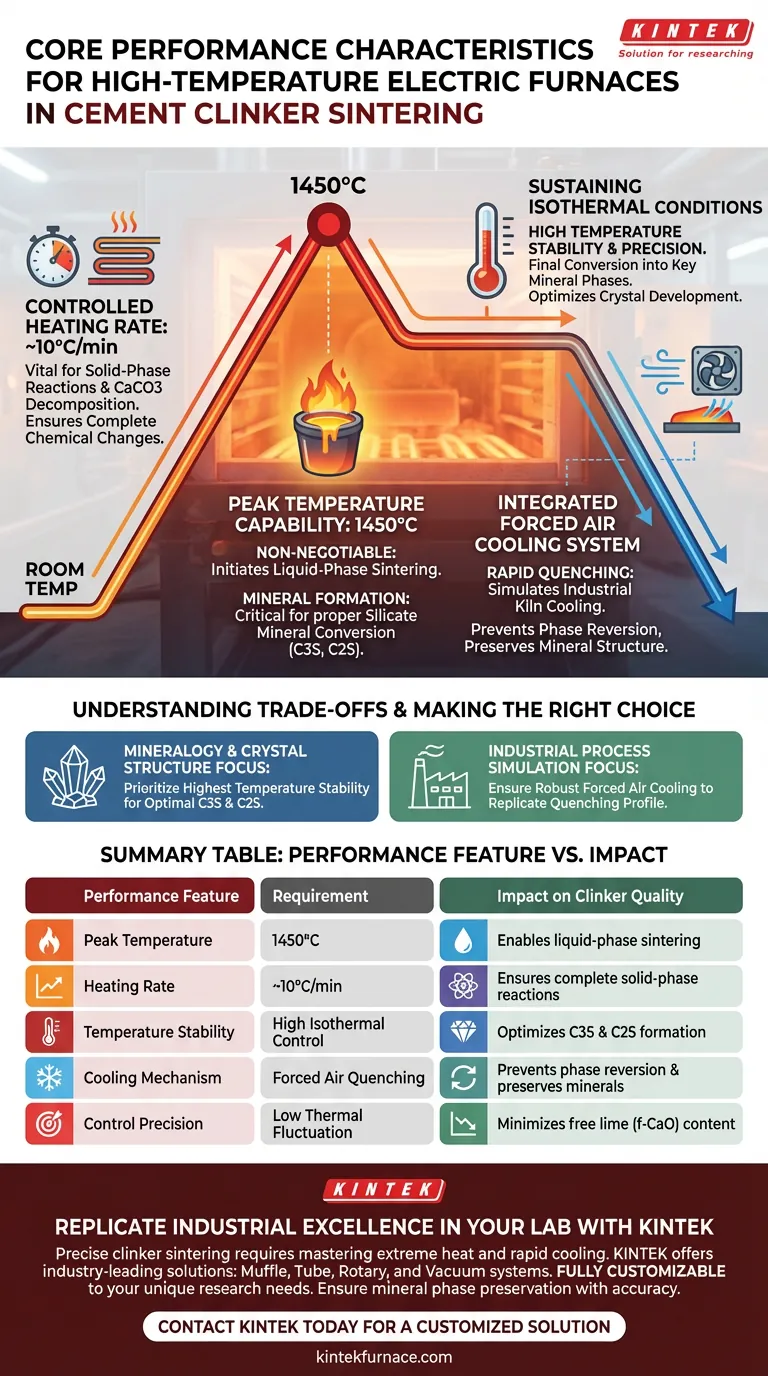

To replicate industrial clinker sintering effectively, a high-temperature electric furnace must feature a robust control system capable of reaching 1450°C and sustaining a stable heating rate of approximately 10°C/min. Crucially, the unit requires integration with a forced air cooling system to simulate rapid quenching, ensuring the mineral phases formed at peak heat are preserved without reversion.

The success of clinker sintering is defined by the furnace's ability to precisely replicate the industrial thermal curve—specifically the transition through solid-phase reactions to liquid-phase sintering—ensuring the proper formation of silicate minerals while minimizing free lime content.

The Thermal Profile for Mineral Formation

Peak Temperature Capability

The furnace must reliably achieve and sustain an ultra-high temperature environment of 1450°C.

This specific threshold is non-negotiable, as it is the temperature required to initiate and maintain liquid-phase sintering.

Without reaching this peak, the raw meal cannot undergo the necessary chemical changes to convert fully into silicate minerals.

Controlled Heating Rates

A high-performance furnace must offer programmable heating rates, specifically capable of maintaining a stable 10°C/min.

This controlled ascent is vital for the preliminary stages of the process, including calcium carbonate decomposition and solid-phase reactions.

Rushing this stage can lead to incomplete reactions before the material even reaches the melting phase.

Precision and Mineral Quality

Sustaining Isothermal Conditions

The equipment must possess the thermal mass and control logic to hold the temperature constant at 1450°C.

It is during this stable holding period that the final conversion of raw materials into key mineral phases takes place.

This stability directly influences the formation of tricalcium silicate (C3S) and dicalcium silicate (C2S).

Accuracy and Free Lime

The precision of the temperature control system is the primary determinant of clinker quality.

Fluctuations at peak temperature can result in poor mineral crystal development.

Furthermore, accurate control is essential to minimize free calcium oxide (f-CaO), a key indicator of incomplete sintering.

Understanding the Trade-offs

The Necessity of Integrated Cooling

A common pitfall in selecting a furnace is focusing solely on the heating element and ignoring the cooling mechanism.

Industrial cement kilns rapidly cool clinker; your laboratory furnace must simulate this to be accurate.

The furnace must integrate with a forced air cooling system to facilitate quenching.

Preventing Phase Reversion

If the clinker cools too slowly inside a well-insulated furnace, mineral phases can undergo reverse transformation.

This reversion alters the chemical composition, rendering the sample unrepresentative of industrial product.

Therefore, the ability to extract heat quickly is just as important as the ability to generate it.

Making the Right Choice for Your Goal

To ensure your equipment selection aligns with your research objectives, consider these priorities:

- If your primary focus is Mineralogy and Crystal Structure: Prioritize a furnace with the highest possible temperature stability to ensure optimal development of C3S and C2S phases.

- If your primary focus is Industrial Process Simulation: Ensure the unit features a robust forced air cooling system to accurately replicate the quenching profile of a cement kiln.

True reliability in clinker sintering comes from a furnace that masters the entire thermal cycle, from controlled heating to rapid cooling.

Summary Table:

| Performance Feature | Requirement | Impact on Clinker Quality |

|---|---|---|

| Peak Temperature | 1450°C | Enables essential liquid-phase sintering |

| Heating Rate | 10°C/min | Ensures complete solid-phase reactions |

| Temperature Stability | High Isothermal Control | Optimizes C3S and C2S mineral formation |

| Cooling Mechanism | Forced Air Quenching | Prevents phase reversion & preserves minerals |

| Control Precision | Low Thermal Fluctuation | Minimizes free lime (f-CaO) content |

Replicate Industrial Excellence in Your Lab

Precise clinker sintering requires a furnace that masters both extreme heat and rapid cooling. KINTEK provides industry-leading high-temperature solutions—including Muffle, Tube, Rotary, and Vacuum systems—specifically designed to meet the rigorous thermal profiles of cement research.

Backed by expert R&D and manufacturing, our systems are fully customizable to your unique quenching and heating rate needs. Ensure your mineral phases are preserved with the accuracy your research demands.

Contact KINTEK today for a customized furnace solution

Visual Guide

References

- Influence of Raw Material Fineness on Clinker Burnability and Cement Performance. DOI: 10.3390/ma18112453

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of industrial-scale cylindrical heat treatment kilns for Moso Bamboo? Scaling for Durability

- What are the primary functions of electric rotary kilns? Achieve Precise High-Temperature Processing

- What temperature limitations exist for electric kilns? Unlock the Secrets of Kiln Heating Elements

- What are rotary kilns used for? Unlocking High-Temperature Processing for Industry

- What are the advantages of electromagnetic heated rotary kilns? Boost Efficiency and Precision in Your Process

- What are the advantages of gas kilns? Unlock Unique Glaze Effects and Faster Firing

- What factors limit the feasibility of electrifying rotary kiln processes? Key Technical & Economic Barriers

- How does material move through the electric heating rotary kiln? Uncover the Mechanics for Uniform Heat Processing