The core advantages of electromagnetic heated rotary kilns are their exceptional thermal efficiency, precise temperature control, and significantly lower operational costs. By generating heat directly within the material rather than transferring it from an external source, this technology offers superior process uniformity, reduces energy waste, and eliminates the emissions associated with traditional fuel-fired systems.

At its core, the shift to electromagnetic heating is about moving from brute-force external heat to precise internal energy transfer. This fundamental change delivers not just energy savings, but a level of process control and product consistency that is difficult to achieve with conventional gas or oil-fired kilns.

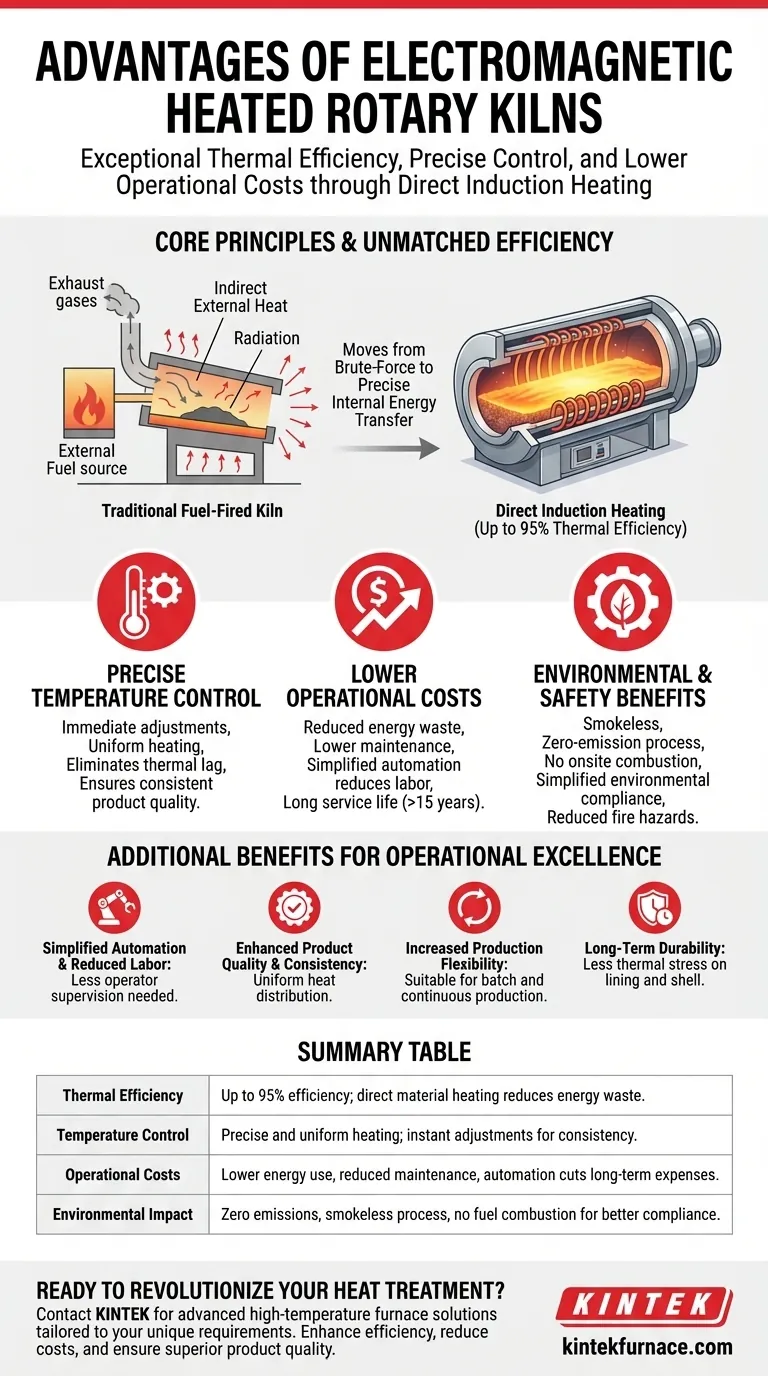

Unpacking the Core Advantages: Efficiency and Control

The primary benefits of electromagnetic rotary kilns stem directly from the physics of induction heating. Unlike traditional methods that heat the kiln's atmosphere and shell to indirectly heat the material, induction creates heat within the target material itself.

The Principle of Direct Induction Heating

Electromagnetic heating uses a magnetic field to induce an electric current directly inside the conductive material being processed. The material's natural electrical resistance causes it to heat up rapidly and uniformly from within.

This process decouples heating from the kiln's atmosphere, leading to a much more efficient and responsive system.

Unmatched Thermal Efficiency

Because energy is transferred directly to the product with minimal loss to the surrounding environment, these kilns can achieve thermal efficiency rates of up to 95%.

This stands in stark contrast to fuel-fired kilns, where a significant portion of energy is lost through exhaust gases and heat radiation from the kiln shell.

Precision Temperature Control

Direct heating allows for immediate and precise temperature adjustments. The system can react instantly to process changes, eliminating the thermal lag common in conventional kilns.

This results in exceptionally uniform heating throughout the material bed, which prevents hot spots, reduces uneven firing, and ensures consistent product quality batch after batch. This level of control is particularly effective at lower temperature ranges where gas kilns often struggle with precision.

How This Translates to Operational Excellence

The technical advantages of induction heating create a cascade of practical benefits that impact everything from labor costs to product quality.

Simplified Automation and Reduced Labor

The precise and responsive nature of electric heating makes it ideal for full automation. There is no complex fuel management, burner tuning, or air-to-fuel ratio to maintain.

This high degree of automation reduces the need for constant operator supervision and simplifies overall plant operations, leading to lower labor requirements.

Enhanced Product Quality and Consistency

By eliminating temperature fluctuations and ensuring even heat distribution, electromagnetic kilns produce a more consistent and higher-quality end product.

This is critical in industries like metallurgy and advanced materials manufacturing, where narrow processing windows are essential for meeting strict specifications.

Increased Production Flexibility

These kilns can be engineered for both batch and continuous production. The ability to precisely control the temperature, atmosphere, and processing time provides versatile heat treatment conditions that can be tailored to a wide range of materials and production goals.

Understanding the Trade-offs and System Integrity

While the advantages are significant, a balanced technical evaluation requires acknowledging the system's specific requirements and long-term considerations.

Initial Capital Investment

The advanced technology and control systems associated with electromagnetic kilns often mean a higher upfront capital cost compared to traditional fuel-fired systems. This investment must be weighed against the long-term operational savings.

Long-Term Durability and Maintenance

Electromagnetic kilns are designed for a long service life, often exceeding 15 years. By heating the material directly, the kiln's refractory lining and steel shell are subjected to less thermal stress, which prolongs their life and lowers overall maintenance costs.

Environmental and Safety Benefits

Perhaps one of the most compelling operational benefits is the elimination of onsite combustion. This provides a smokeless, zero-emission process that eliminates SO₂, ash, and other pollutants.

Furthermore, removing the need for fuel storage and transport logistics greatly reduces fire hazards and simplifies environmental compliance.

Making the Right Choice for Your Application

Choosing the right kiln technology depends entirely on your primary production and business goals.

- If your primary focus is maximizing product quality and consistency: The unparalleled uniformity and precision of induction heating offer superior control over your final product specifications.

- If your primary focus is reducing long-term operational costs: The combination of 95% thermal efficiency, lower maintenance, and reduced labor can deliver a powerful return on investment over the system's lifespan.

- If your primary focus is meeting strict environmental regulations: The complete elimination of fuel combustion and associated emissions makes this a clean, future-proof technology for any facility.

By shifting from external combustion to direct internal heating, electromagnetic rotary kilns offer a level of control and efficiency that can redefine your production process.

Summary Table:

| Advantage | Description |

|---|---|

| Thermal Efficiency | Up to 95% efficiency by heating material directly, reducing energy waste. |

| Temperature Control | Precise and uniform heating with instant adjustments for consistent product quality. |

| Operational Costs | Lower energy use, reduced maintenance, and automation cut long-term expenses. |

| Environmental Impact | Zero emissions, smokeless process, and no fuel combustion for better compliance. |

Ready to revolutionize your heat treatment process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our electromagnetic heated rotary kilns can enhance your efficiency, reduce costs, and ensure superior product quality!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results