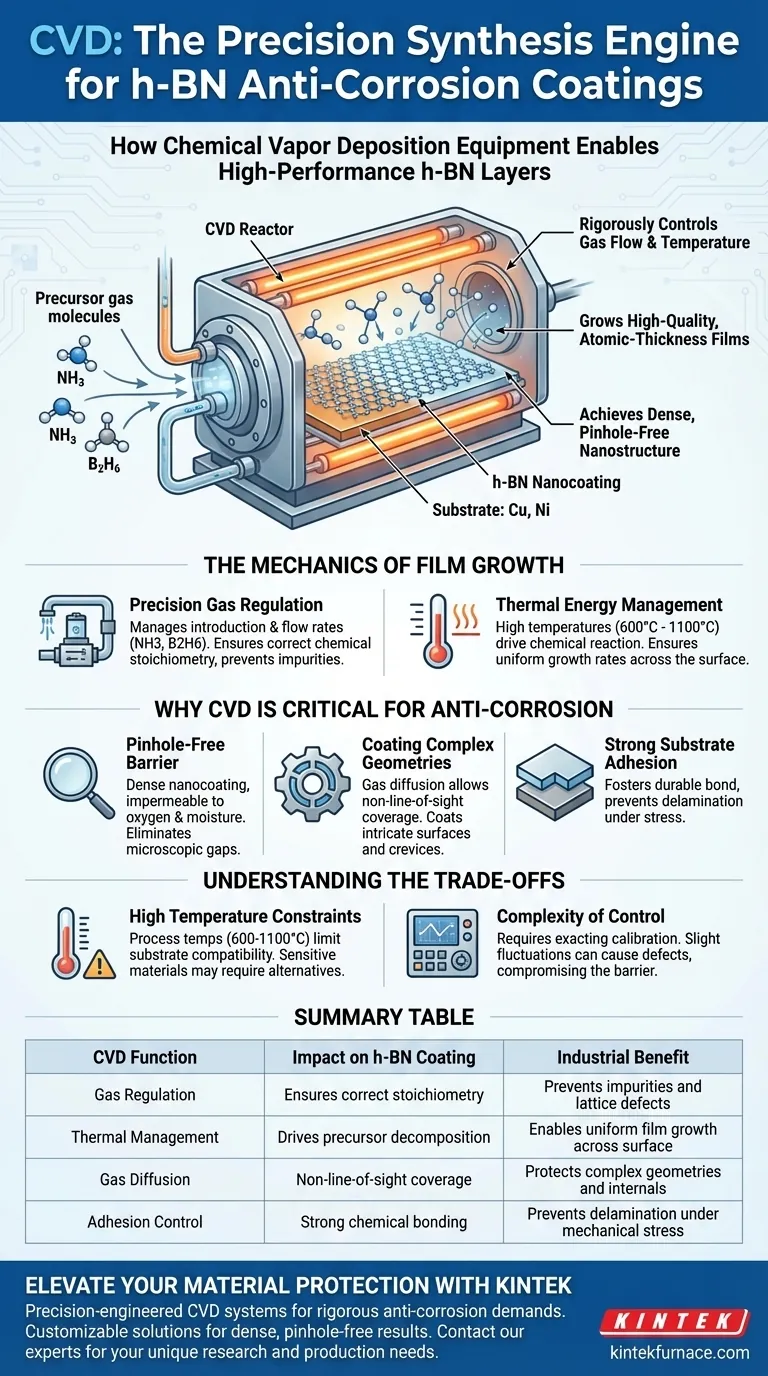

Chemical Vapor Deposition (CVD) equipment functions as the precision synthesis engine required to generate high-performance hexagonal boron nitride (h-BN) coatings. Its primary role is to rigorously control the flow of specific precursor gases and reaction temperatures to grow high-quality films of atomic thickness directly onto metal substrates. This level of control is the only way to achieve the dense, pinhole-free nanostructure necessary for h-BN to serve as an effective anti-corrosion barrier.

The core value of CVD equipment lies in its ability to manufacture continuous, impermeable h-BN layers by orchestrating gas dynamics and thermal energy. This process eliminates microscopic defects, unlocking the material’s inherent oxidation resistance and chemical inertness.

The Mechanics of Film Growth

Precision Gas Regulation

The equipment manages the introduction and flow rates of specific precursor gases, typically ammonia and diborane.

By fine-tuning these inputs, the system ensures the correct chemical stoichiometry is present to form the h-BN lattice. This prevents impurities that could compromise the coating's integrity.

Thermal Energy Management

CVD systems utilize high temperatures to drive the chemical reaction necessary for film growth.

This thermal energy breaks down the precursor gases, allowing boron and nitrogen atoms to deposit and bond onto the substrate. The equipment maintains these temperatures to ensure uniform growth rates across the surface.

Why CVD is Critical for Anti-Corrosion

Creating a Pinhole-Free Barrier

For a coating to prevent corrosion, it must be impermeable to oxygen and moisture.

CVD enables the preparation of dense nanocoatings that are free of "pinholes" or microscopic gaps. This continuous structure allows the h-BN to fully utilize its barrier properties and oxidation resistance.

Coating Complex Geometries

Unlike physical application methods that require a direct line of sight, CVD relies on gas diffusion.

This allows the equipment to coat intricate surfaces, internal geometries, and difficult-to-reach seal areas. The gas penetrates every crevice, ensuring comprehensive protection regardless of the part's shape.

Strong Substrate Adhesion

The CVD process fosters a strong, durable bond between the h-BN film and the metal substrate.

This prevents the coating from delaminating under stress, ensuring it remains intact even in high-stress environments. Common substrates for this process include copper and nickel.

Understanding the Trade-offs

High Temperature Constraints

Standard Thermal CVD processes typically require temperatures ranging from 600°C to 1100°C to effectively break down precursor gases.

This high thermal requirement limits the types of substrates that can be coated without sustaining damage. Materials sensitive to high heat may require specialized variations of the CVD process or alternative coating methods.

Complexity of Control

Achieving a "pinhole-free" state is not automatic; it requires exacting calibration of the equipment.

If gas flows or temperatures fluctuate even slightly, the resulting film may develop defects. These imperfections compromise the anti-corrosion barrier, rendering the coating ineffective.

Making the Right Choice for Your Goal

When evaluating CVD for h-BN applications, consider your specific performance requirements:

- If your primary focus is absolute barrier integrity: Prioritize equipment with advanced flow control to ensure the film is dense and pinhole-free.

- If your primary focus is complex part geometry: Leverage the non-line-of-sight nature of CVD to protect internal surfaces and intricate details that sprays cannot reach.

- If your primary focus is substrate compatibility: Verify that your base metal can withstand the 600°C to 1100°C process temperatures required for thermal CVD.

Ultimately, CVD equipment bridges the gap between raw chemical potential and a practical, industrial-grade protective shield.

Summary Table:

| CVD Function | Impact on h-BN Coating | Industrial Benefit |

|---|---|---|

| Gas Regulation | Ensures correct stoichiometry | Prevents impurities and lattice defects |

| Thermal Management | Drives precursor decomposition | Enables uniform film growth across surface |

| Gas Diffusion | Non-line-of-sight coverage | Protects complex geometries and internals |

| Adhesion Control | Strong chemical bonding | Prevents delamination under mechanical stress |

Elevate Your Material Protection with KINTEK

Unlock the full potential of hexagonal boron nitride coatings with precision-engineered CVD systems from KINTEK. Backed by expert R&D and world-class manufacturing, we provide high-performance CVD systems, Muffle, Tube, and Vacuum furnaces specifically designed to meet the rigorous demands of anti-corrosion applications. Whether you are coating intricate geometries or require absolute barrier integrity, our customizable lab high-temp solutions ensure dense, pinhole-free results every time.

Ready to optimize your thin-film synthesis? Contact our technical experts today to find the perfect system for your unique research and production needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the basic configuration of CVD coating equipment? Unlock High-Quality Thin Film Deposition

- What are the advantages of chemical vapor sterilization? Protect Your Metal Instruments from Rust and Dulling

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- What is the function of H2 in DLI-PP-CVD for MoS2? Optimize Crystalline Quality and Purity

- What are the applications of CVD method? Unlock High-Performance Thin Films & Coatings

- How do sodium-droplet eutectics (SODE) act as catalysts for MoS2 CVD growth? Achieve High-Quality Thin Film Synthesis

- Why is industrial-grade copper foam utilized as a growth substrate for ReO3–Cu2Te? Enhance CVD Catalyst Performance

- What are the methods for depositing silicon dioxide using CVD? Optimize Your Semiconductor Process