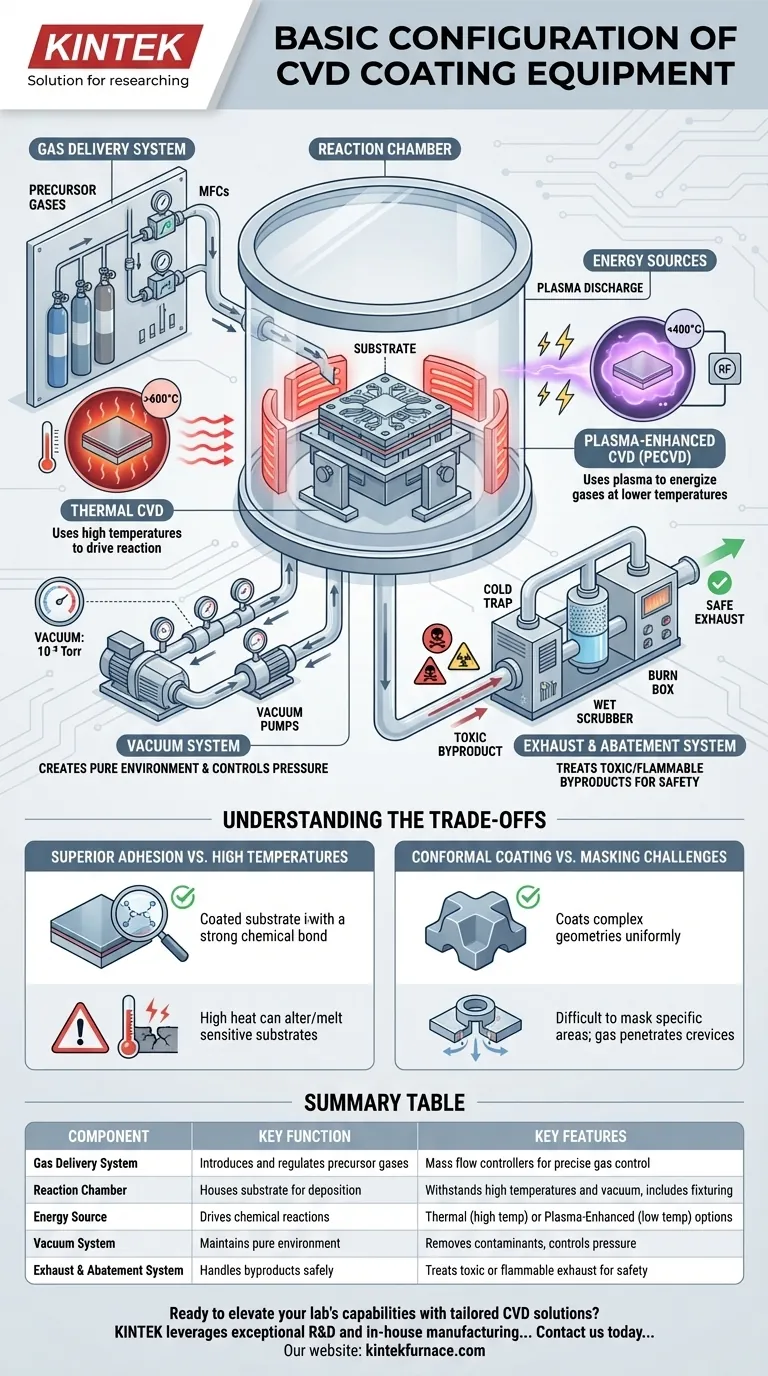

At its core, all Chemical Vapor Deposition (CVD) equipment is a highly controlled chemical reactor designed for growing thin films on a substrate. The basic configuration consists of a gas delivery system to introduce reactive precursors, a reaction chamber where the substrate is heated or exposed to plasma, a vacuum system to maintain a pure environment, and an exhaust abatement system to safely handle toxic byproducts.

Understanding the components of a CVD system is less about the hardware itself and more about how each part serves as a control lever for the chemical reaction at the substrate's surface. The configuration is designed entirely around creating and maintaining the precise conditions—temperature, pressure, and gas chemistry—needed for high-quality film growth.

Deconstructing the CVD System: From Gas to Film

A CVD system functions by flowing precursor gases over a substrate in a controlled environment, where an energy source drives a chemical reaction that deposits a solid film. Each part of the equipment plays a critical role in managing this process flow.

The Gas Delivery System: Sourcing the Reaction

The process begins with one or more precursor gases, which contain the elements you want to deposit.

This system uses mass flow controllers (MFCs) to precisely regulate the amount of each gas entering the chamber. This control is fundamental to achieving the correct film chemistry and growth rate.

The Reaction Chamber: The Heart of the Process

The reaction chamber is the sealed vessel where the deposition occurs. It is designed to withstand high temperatures and vacuum conditions.

Inside the chamber, the substrate is held by specialized fixturing. Proper fixturing is critical for ensuring uniform heating and gas flow across the part, which leads to consistent coating coverage and prevents damage.

The Energy Source: Driving the Chemical Reaction

CVD reactions require energy to proceed. This is typically supplied in one of two ways.

Thermal CVD uses resistance heaters or lamps to heat the substrate to high temperatures (often >600°C), giving the precursor gas molecules the energy they need to react on the surface.

Plasma-Enhanced CVD (PECVD) uses an electric field to generate a plasma within the chamber. This plasma energizes the precursor gases, allowing the reaction to occur at much lower temperatures.

The Vacuum System: Creating the Ideal Environment

Nearly all CVD processes are run under vacuum. A system of pumps removes air and other contaminants from the chamber before introducing the precursor gases.

This vacuum environment serves two purposes: it prevents unwanted reactions with atmospheric gases (like oxygen and nitrogen) and allows for precise control over the process pressure.

The Exhaust & Abatement System: Ensuring Safety

The unreacted precursor gases and chemical byproducts from the reaction are exhausted from the chamber.

These byproducts are often toxic, flammable, or environmentally harmful. An abatement system, such as a cold trap, wet scrubber, or chemical burn box, is essential for treating this exhaust stream before it is released, ensuring operator safety and environmental compliance.

Understanding the Trade-offs and Process Realities

The configuration of CVD equipment directly leads to its primary advantages and limitations. Understanding these trade-offs is key to determining if it is the right technology for your application.

Superior Adhesion vs. High Temperatures

CVD creates a true chemical bond between the coating and the substrate, resulting in superior adhesion compared to line-of-sight processes like PVD.

However, the high temperatures required for most thermal CVD processes limit the types of substrate materials that can be coated. The heat can alter the properties or even melt materials like plastics, aluminum, or certain steels.

Conformal Coating vs. Masking Challenges

Because the process is based on a chemical gas reaction, CVD is not limited to line-of-sight. It can coat complex, 3D shapes and internal surfaces with a uniform, conformal layer.

The downside of this excellent conformality is that it is very difficult to mask specific areas of a part that you do not want coated. The reactive gas will find its way into any unsealed crevice.

The Critical Role of Surface Preparation

The quality of the chemical bond depends on a perfectly clean surface. Any contaminants, such as oils or oxides, must be rigorously removed from the substrate before it enters the coating chamber.

This pre-treatment step is a critical part of the overall process that the equipment and fixturing must be designed to support.

Making the Right Choice for Your Goal

Your specific goal will determine which aspects of the CVD equipment configuration are most important.

- If your primary focus is coating complex, 3D geometries: The non-line-of-sight nature of a CVD reactor is ideal, but you must ensure your substrate material can withstand the system's processing temperature.

- If your primary focus is coating temperature-sensitive materials (like polymers or certain alloys): A standard thermal CVD configuration is unsuitable; you must specify a plasma-enhanced (PECVD) system designed for low-temperature operation.

- If your primary focus is operational safety and environmental compliance: The exhaust and abatement system is a non-negotiable part of the configuration that requires significant planning and investment to handle hazardous byproducts effectively.

By understanding how each component serves the underlying chemical process, you can more effectively specify, operate, or evaluate CVD technology for your needs.

Summary Table:

| Component | Key Function | Key Features |

|---|---|---|

| Gas Delivery System | Introduces and regulates precursor gases | Mass flow controllers for precise gas control |

| Reaction Chamber | Houses substrate for deposition | Withstands high temperatures and vacuum, includes fixturing |

| Energy Source | Drives chemical reactions | Thermal (high temp) or Plasma-Enhanced (low temp) options |

| Vacuum System | Maintains pure environment | Removes contaminants, controls pressure |

| Exhaust & Abatement System | Handles byproducts safely | Treats toxic or flammable exhaust for safety |

Ready to elevate your lab's capabilities with tailored CVD solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD equipment. Our deep customization ensures precise alignment with your experimental needs, whether you're coating complex geometries or temperature-sensitive materials. Contact us today to discuss how our expertise can drive your research forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition