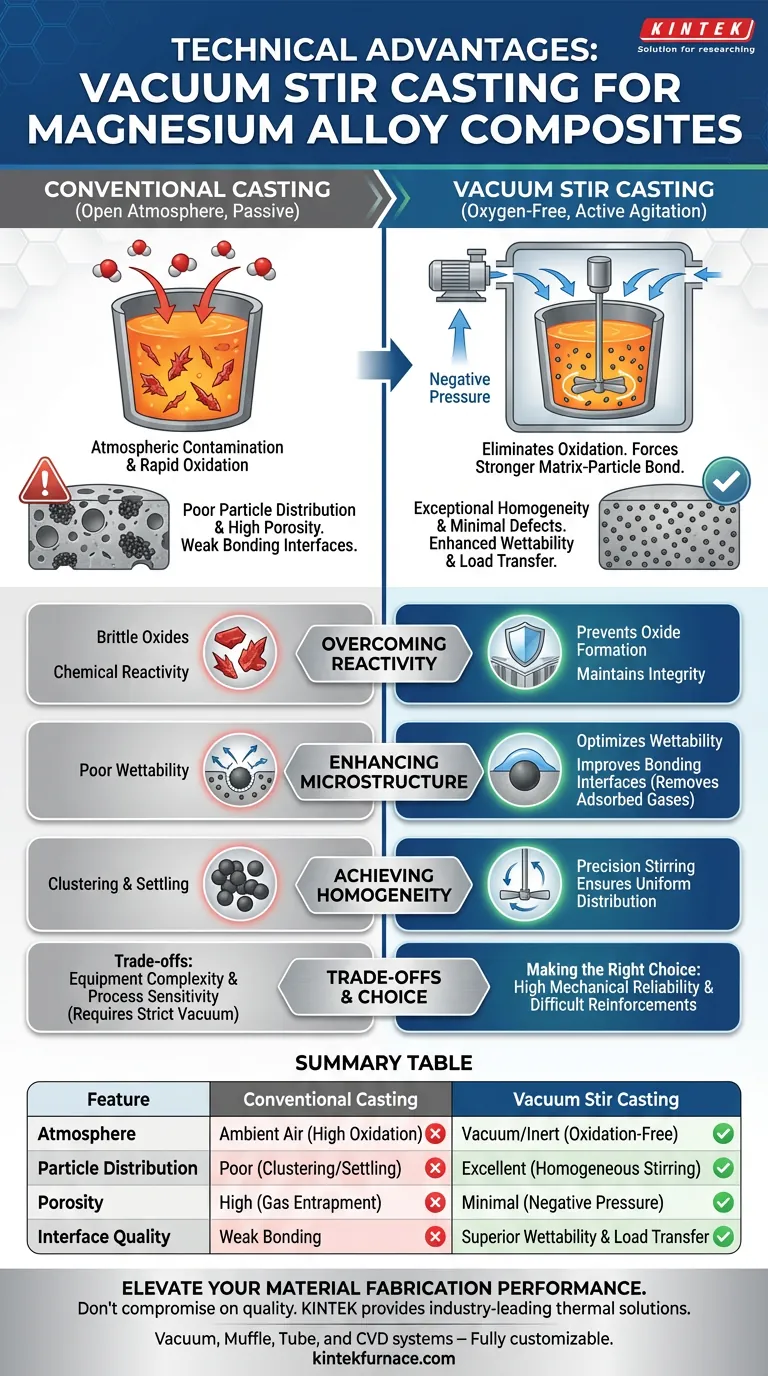

A vacuum stir casting system fundamentally transforms the quality of magnesium alloy composites by combining an oxygen-free environment with active mechanical agitation. While conventional casting leaves molten metal vulnerable to atmospheric contamination and particle clustering, this system isolates the magnesium to prevent oxidation and uses negative pressure to force a stronger bond between the metal matrix and reinforcement particles.

The synergy of vacuum isolation and precision stirring addresses the two critical failure points in magnesium fabrication: chemical reactivity and poor particle distribution. The result is a composite material with exceptional internal homogeneity and significantly fewer structural defects compared to standard casting methods.

Overcoming Magnesium's Reactivity

The Challenge of Oxidation

Magnesium alloys are notorious for their high chemical reactivity. In conventional casting scenarios, exposing molten magnesium to air invariably leads to rapid oxidation reactions.

The Vacuum Solution

A vacuum stir casting system integrates a vacuum evacuation mechanism that effectively isolates the melt from the atmosphere. By maintaining a negative pressure environment, the system prevents oxygen from contacting the heated metal, stopping the formation of brittle oxides that would otherwise compromise the material.

Enhancing Microstructural Integrity

Optimizing Wettability

One of the hardest parts of composite fabrication is getting the liquid metal to "wet" or stick to the solid reinforcement particles. Mechanical stirring performed under vacuum significantly enhances this wettability.

Improving Bonding Interfaces

The vacuum environment aids in removing adsorbed gases from the surface of reinforcement particles, such as waste glass powder or silicon nitride. This promotes a clean, tight interface between the magnesium matrix and the reinforcements, which is critical for load transfer.

Achieving Homogeneity

Standard casting often suffers from particle settling or clustering. The precision mechanical stirring ensures that reinforcements are distributed evenly throughout the matrix, resulting in a highly homogeneous internal structure.

Understanding the Trade-offs

Equipment Complexity

Unlike simple gravity casting, vacuum stir casting requires sophisticated machinery. You must manage vacuum seals, pumps, and stirring mechanisms simultaneously, increasing the technical complexity of the operation.

Process Sensitivity

The benefits of this system rely on maintaining a strict vacuum. Any leakage or failure in the evacuation system can immediately reintroduce oxidation, negating the primary advantage of the equipment.

Making the Right Choice for Your Goal

To determine if this technology aligns with your fabrication needs, consider your specific performance requirements:

- If your primary focus is mechanical reliability: Use vacuum stir casting to eliminate the inclusion of brittle oxides and gas porosity that inevitably weaken the material.

- If your primary focus is difficult reinforcements: Rely on this system when using particles that resist wetting (like silicon nitride), as the vacuum pressure is essential for forcing proper matrix-particle contact.

By controlling the atmosphere and the agitation simultaneously, you transition from simply casting metal to engineering a high-performance composite.

Summary Table:

| Feature | Conventional Casting | Vacuum Stir Casting |

|---|---|---|

| Atmosphere | Ambient Air (High Oxidation) | Vacuum/Inert (Oxidation-Free) |

| Particle Distribution | Poor (Clustering/Settling) | Excellent (Homogeneous Stirring) |

| Porosity | High (Gas Entrapment) | Minimal (Negative Pressure) |

| Interface Quality | Weak Bonding | Superior Wettability & Load Transfer |

Elevate Your Material Fabrication Performance

Don't let oxidation and poor particle distribution compromise your high-performance composites. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Our range of Vacuum, Muffle, Tube, and CVD systems are fully customizable to meet the unique demands of magnesium alloy fabrication and beyond.

Ready to transform your laboratory's manufacturing capabilities? Contact us today to discuss your specific project needs with our technical specialists.

Visual Guide

References

- Shubham Sharma, Emad A. A. Ismail. Enhancing tribo-mechanical, microstructural morphology, and corrosion performance of AZ91D-magnesium composites through the synergistic reinforcements of silicon nitride and waste glass powder. DOI: 10.1038/s41598-024-52804-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is electromagnetic stirring necessary for NbC-Cr7C3@graphene in W18Cr4V steel? Boost Alloy Performance

- What are the advantages of induction furnace? Achieve Superior Efficiency, Control, and Cleanliness

- What role does a high-vacuum melting furnace play in the modification of Ni 620 brazing filler metal with tungsten?

- What industries commonly use vacuum casting and for what applications? Discover Versatile Solutions for Prototyping and High-Performance Parts

- What industries benefit from induction heat treatment and why? Boost Efficiency and Durability in Metalworking

- What are the major challenges faced by the IGBT induction melting furnace market? Navigating High Costs and Complexity

- How does the induction coil in a vacuum furnace work? Achieve Contamination-Free, Rapid Metal Heating

- What are the technical advantages of using a Vacuum Induction Melting furnace in the development of advanced packaging steel?