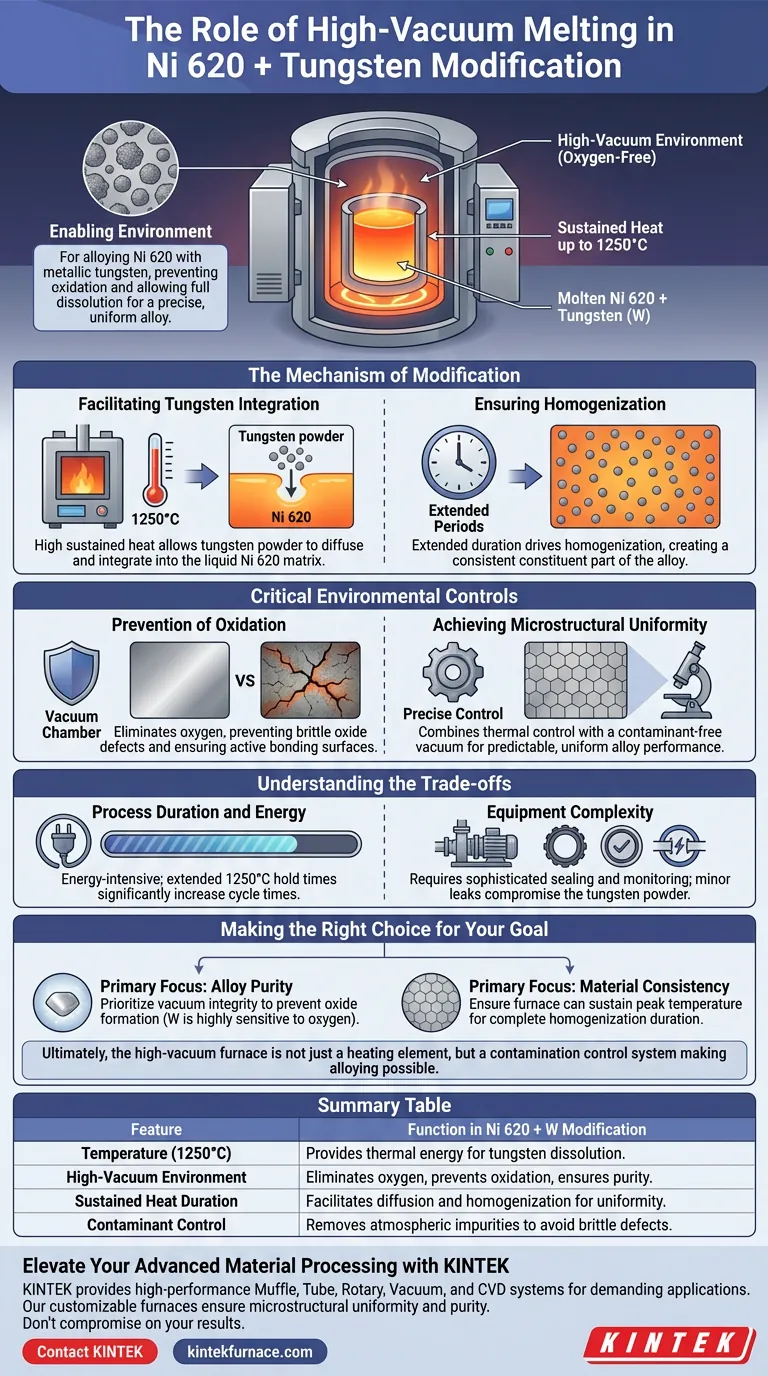

The high-vacuum melting furnace acts as the enabling environment for alloying Ni 620 brazing filler metal with metallic tungsten (W) powder. By maintaining temperatures up to 1250 °C in an oxygen-free setting, the furnace allows the refractory tungsten to fully dissolve into the nickel matrix without degrading, resulting in a chemically precise and structurally uniform alloy.

The core function of the high-vacuum furnace is to overcome the physical disparity between the nickel base and tungsten powder. It prevents rapid oxidation while sustaining the necessary heat and time required for high-melting-point tungsten to homogenize within the filler metal.

The Mechanism of Modification

Facilitating Tungsten Integration

Tungsten is a refractory metal with an extremely high melting point, making it difficult to mix with standard nickel-based alloys under normal conditions.

The high-vacuum melting furnace operates at specific elevated temperatures, typically reaching 1250 °C.

This sustained heat allows the tungsten powder to diffuse and integrate effectively into the liquid Ni 620 matrix.

Ensuring Homogenization

Simply melting the metals is insufficient; the elements must be evenly distributed to create a reliable filler metal.

The furnace maintains these high temperatures for extended periods.

This duration drives the homogenization process, ensuring the tungsten does not remain as discrete particles but becomes a constituent part of the alloy's microstructure.

Critical Environmental Controls

Prevention of Oxidation

The primary danger during this modification process is the formation of oxides.

Both nickel alloys and tungsten are susceptible to oxidation at elevated temperatures, which would create brittle defects and prevent proper alloying.

The high-vacuum environment eliminates atmospheric oxygen, ensuring the metal surfaces remain "fresh" and chemically active for bonding.

Achieving Microstructural Uniformity

The quality of a brazing filler metal depends on its consistency.

By combining precise thermal control with a contaminant-free vacuum, the furnace yields a modified alloy with a uniform microstructure.

This uniformity ensures that the modified Ni 620 performs predictably during actual brazing applications.

Understanding the Trade-offs

Process Duration and Energy

While essential for quality, high-vacuum melting is an energy-intensive process.

The requirement to hold the alloy at 1250 °C for extended periods to ensure full tungsten integration significantly increases cycle times compared to standard atmospheric melting.

Equipment Complexity

Achieving and maintaining a high-vacuum state requires sophisticated sealing and pumping systems.

Operators must strictly monitor vacuum levels, as even minor leaks can introduce enough oxygen to compromise the tungsten powder before it dissolves into the nickel matrix.

Making the Right Choice for Your Goal

To optimize the modification of Ni 620 with tungsten, consider your specific processing priorities:

- If your primary focus is alloy purity: Prioritize vacuum integrity to prevent oxide formation, as tungsten is highly sensitive to oxygen at 1250 °C.

- If your primary focus is material consistency: Ensure the furnace is capable of sustaining the peak temperature for the extended duration required for complete homogenization.

Ultimately, the high-vacuum furnace is not just a heating element, but a contamination control system that makes the alloying of refractory tungsten possible.

Summary Table:

| Feature | Function in Ni 620 + W Modification |

|---|---|

| Temperature (1250 °C) | Provides the thermal energy required to dissolve refractory tungsten into the nickel matrix. |

| High-Vacuum Environment | Eliminates oxygen to prevent oxidation of nickel and tungsten, ensuring chemical purity. |

| Sustained Heat Duration | Facilitates diffusion and homogenization for a uniform microstructural distribution. |

| Contaminant Control | Removes atmospheric impurities that could lead to brittle defects in the filler metal. |

Elevate Your Advanced Material Processing with KINTEK

Precision brazing and alloying demand uncompromising thermal environments. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the most demanding lab and industrial applications.

Whether you are modifying Ni 620 filler metals or developing custom refractory alloys, our customizable high-temperature furnaces ensure the microstructural uniformity and purity your research requires. Don't compromise on your results.

Contact KINTEK today to discuss your unique heat treatment needs

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity