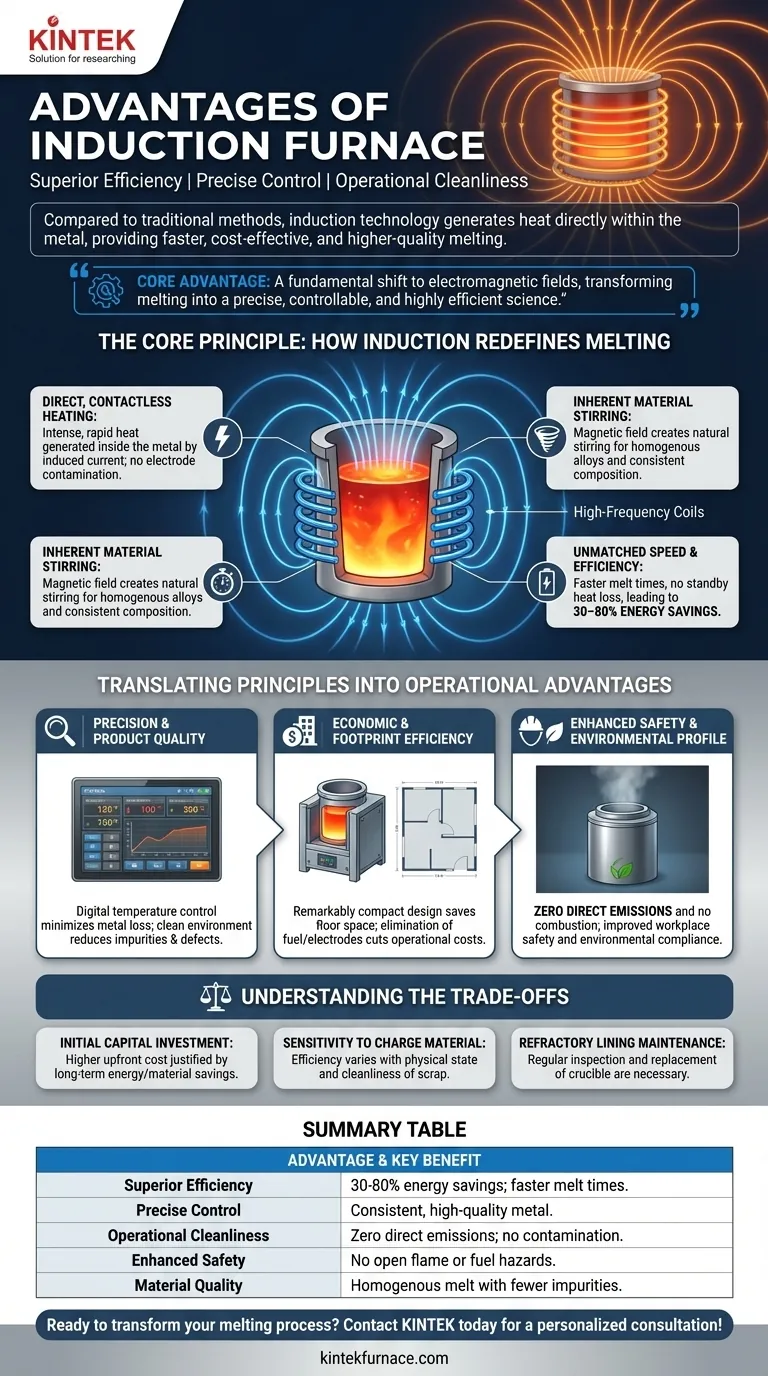

In short, the advantages of an induction furnace are superior efficiency, precise control, and operational cleanliness. Compared to traditional fuel-fired methods, induction technology provides a faster, more cost-effective, and higher-quality melting process by generating heat directly within the metal itself. This eliminates many of the costs, impurities, and inefficiencies associated with burning fossil fuels.

The core advantage of an induction furnace is not just a list of benefits, but a fundamental shift in heating methodology. By using electromagnetic fields instead of external combustion, it transforms melting from an approximate art into a precise, controllable, and highly efficient science.

The Core Principle: How Induction Redefines Melting

To understand the advantages, you must first understand the mechanism. An induction furnace does not burn fuel. Instead, it uses a powerful, high-frequency magnetic field to induce an electric current directly within the metal charge.

Direct, Contactless Heating

The resistance of the metal to this induced current generates intense, rapid heat from the inside out. This is fundamentally different from traditional furnaces that must heat the outside of the material and wait for the energy to conduct inward.

Because the heating element (the magnetic field) never touches the material, there is no contamination from electrodes or combustion by-products.

Inherent Material Stirring

The same magnetic field that generates heat also creates a natural stirring action within the molten bath. This ensures a homogenous mix, which is critical for producing high-quality alloys with a consistent chemical composition.

Unmatched Speed and Efficiency

Heating from within is dramatically faster, with melt times measured in minutes rather than hours. There is also no standby heat loss, as energy is only consumed when the furnace is actively melting.

This direct efficiency can result in energy savings of 30–80% compared to older methods, significantly reducing long-term operational costs.

Translating Principles into Operational Advantages

The underlying physics of induction melting delivers tangible benefits across production, finance, and safety.

Precision and Product Quality

The ability to manage power input with digital accuracy allows for extremely precise temperature control. This minimizes metal loss due to overheating and prevents the formation of undesirable microstructures.

The clean melting environment, free from combustion gases, results in a final product with fewer impurities and gas-related defects.

Economic and Footprint Efficiency

Induction furnaces are remarkably compact, requiring less floor space than their traditional counterparts.

The elimination of fuel and electrodes removes entire categories of operational costs and logistical challenges related to storing and handling combustible materials.

Enhanced Safety and Environmental Profile

With no open flame or fossil fuel combustion, the induction process produces zero direct emissions. This makes it an environmentally friendly technology that helps meet stringent regulations.

The absence of fuel also dramatically improves workplace safety by removing the risks associated with fuel storage, transportation, and combustion hazards.

Understanding the Trade-offs

No technology is without its considerations. An objective evaluation must acknowledge the potential challenges.

Initial Capital Investment

Induction furnace systems are technologically advanced and typically require a higher upfront capital investment compared to simpler, traditional furnace types. The long-term savings in energy and materials, however, often justify this initial cost.

Sensitivity to Charge Material

The efficiency of the process can be affected by the physical state and cleanliness of the metal being charged. Very loose or dirty scrap may not couple as efficiently with the magnetic field and can produce smoke or slag.

Refractory Lining Maintenance

The crucible, or refractory lining, that holds the molten metal is a critical component that wears over time. It requires regular inspection, maintenance, and eventual replacement, which represents a key recurring operational cost and source of downtime.

Making the Right Choice for Your Operation

Choosing the correct melting technology depends entirely on your primary objectives.

- If your primary focus is process control and quality: The precise temperature regulation and electromagnetic stirring of an induction furnace are unparalleled for producing consistent, high-grade metals.

- If your primary focus is operational cost reduction: The significant energy efficiency and elimination of fuel costs provide a strong, long-term economic advantage that can offset a higher initial investment.

- If your primary focus is environmental compliance and safety: The lack of combustion and associated fuel handling makes induction the cleanest and safest melting technology available.

Ultimately, adopting an induction furnace is a strategic decision that prioritizes precision, long-term efficiency, and operational safety over lower initial capital costs.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Efficiency | 30-80% energy savings vs. traditional methods; faster melt times. |

| Precise Control | Digital temperature management for consistent, high-quality metal. |

| Operational Cleanliness | Zero direct emissions; no contamination from fuel or electrodes. |

| Enhanced Safety | No open flame or combustible fuel hazards. |

| Material Quality | Electromagnetic stirring ensures a homogenous melt with fewer impurities. |

Ready to transform your melting process with the precision and efficiency of an induction furnace?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions for diverse industrial and laboratory applications. Our product line, including high-temperature Muffle, Tube, and Vacuum Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique operational requirements.

Let our experts help you select or custom-engineer the perfect furnace to boost your productivity, reduce costs, and enhance safety. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications