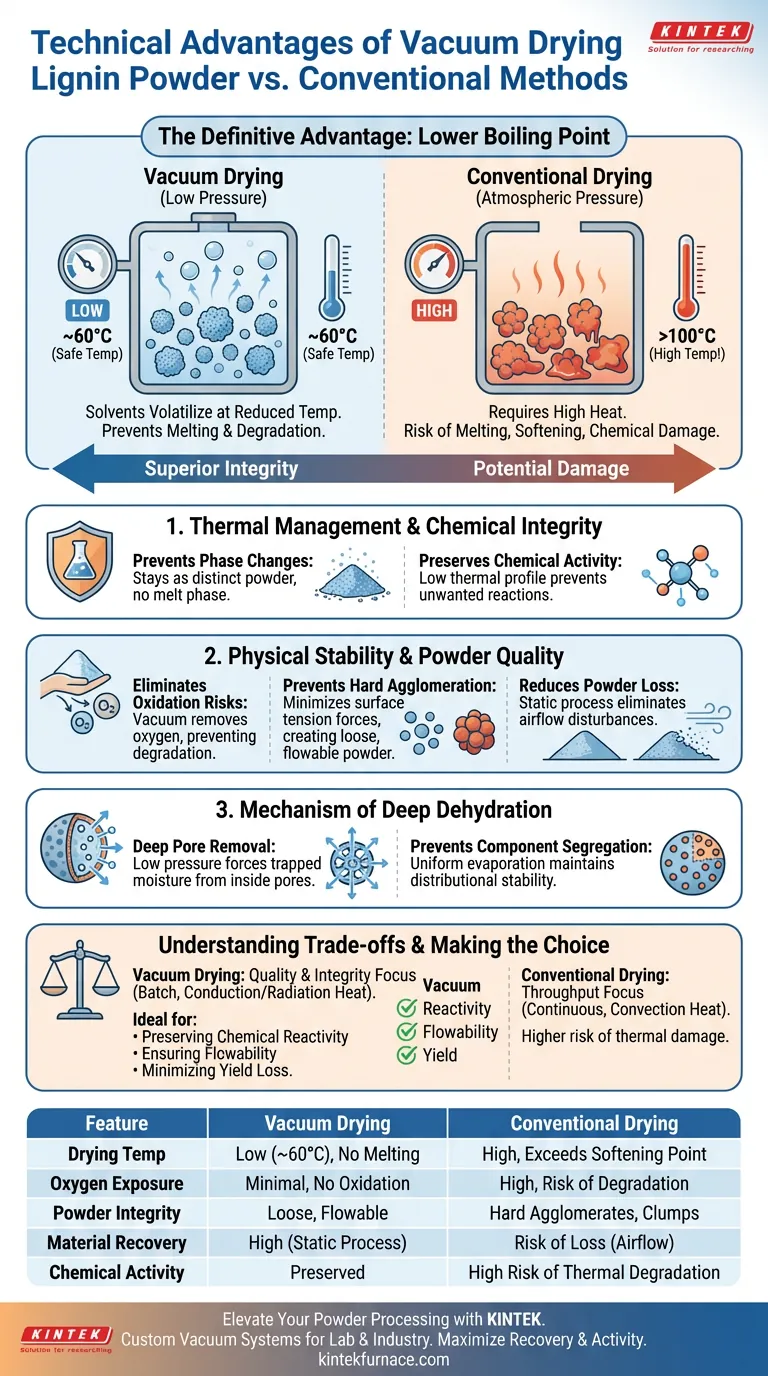

The definitive technical advantage of using a vacuum drying oven for lignin powder is the ability to lower the boiling point of solvents and moisture, allowing them to volatilize at significantly reduced temperatures (around 60 °C). Because lignin is heat-sensitive, this low-temperature process effectively removes volatile components while preventing the material from self-melting, softening, or chemically degrading.

By creating a low-pressure environment, vacuum drying decouples evaporation from high heat. This ensures the complete removal of moisture without compromising the lignin’s physical structure or chemical reactivity, a common failure point in conventional atmospheric drying.

Thermal Management and Chemical Integrity

Preventing Phase Changes

Conventional drying often requires temperatures that exceed the softening point of lignin. By reducing the internal pressure, a vacuum oven allows water and solvents to evaporate at roughly 60 °C. This prevents the lignin from entering a "melt" phase or softening, ensuring the powder remains distinct and processable.

Preserving Chemical Activity

High heat acts as a catalyst for unwanted reactions. By maintaining a low thermal profile, you prevent thermal degradation of the precursor material. This preservation is critical for maintaining the specific chemical activity required for the lignin's downstream applications.

Physical Stability and Powder Quality

Eliminating Oxidation Risks

Lignin is an organic polymer susceptible to oxidation. Vacuum drying inherently removes oxygen from the chamber. This prevents oxidative degradation that typically occurs when organic powders are exposed to heated air, ensuring the purity of the material.

Preventing Hard Agglomeration

In conventional drying, the evaporation of liquid can create strong surface tension forces (liquid bridges) that pull particles together into hard clumps. Vacuum drying minimizes these forces. The result is a loose, flowable powder free of severe secondary agglomeration, which is essential for uniform molding or mixing later.

Reducing Powder Loss

Conventional dryers often utilize hot airflow to transport heat and remove moisture. For ultra-fine lignin powders, this airflow can physically blow the material away, leading to yield loss. Vacuum drying is a static process that eliminates airflow disturbances, maximizing material recovery.

Mechanism of Dehydration

Deep Pore Solvent Removal

Lignin often forms porous agglomerates where moisture is trapped deep inside. Vacuum conditions lower the pressure within these pores, forcing trapped moisture and gas bubbles to expand and escape. This ensures thorough internal drying rather than just surface evaporation.

Preventing Component Segregation

When drying occurs rapidly at high temperatures (atmospheric), moisture rushes to the surface, often carrying dissolved components with it (the capillary effect). Vacuum drying promotes a more uniform evaporation rate. This prevents the segregation of active components toward the outer surface, maintaining distributional stability within the particle.

Understanding the Trade-offs

Throughput vs. Quality

While vacuum drying offers superior quality, it is generally a batch process. It may lack the continuous high-throughput speed of spray drying or flash drying. It is a choice optimized for material integrity rather than raw production volume.

Heat Transfer Limitations

Because there is no air to convectionally transfer heat, vacuum drying relies on conduction (heated shelves) or radiation. This requires careful management of the temperature gradient to ensure the powder closest to the heat source does not overheat while the center of the batch dries.

Making the Right Choice for Your Goal

- If your primary focus is preserving chemical reactivity: Choose vacuum drying to maintain the precursor's active sites by keeping process temperatures below the threshold of thermal degradation.

- If your primary focus is powder flowability: Rely on vacuum drying to prevent the formation of hard agglomerates and clumps caused by liquid bridge forces.

- If your primary focus is minimizing yield loss: Use vacuum drying to eliminate airflow disturbances that disperse fine powders during processing.

The vacuum drying process effectively shifts the physics of evaporation in your favor, allowing you to achieve dryness without paying the penalty of thermal damage.

Summary Table:

| Feature | Vacuum Drying Oven | Conventional Atmospheric Drying |

|---|---|---|

| Drying Temperature | Low (~60°C); prevents melting | High; often exceeds softening point |

| Oxygen Exposure | Minimal; prevents oxidation | High; risk of oxidative degradation |

| Powder Integrity | Loose, flowable; no hard clumps | High risk of hard agglomeration |

| Material Recovery | Static process; zero airflow loss | Airflow can cause fine powder loss |

| Chemical Activity | Preserved via low thermal profile | High risk of thermal degradation |

Elevate Your Powder Processing with KINTEK

Don't compromise the chemical integrity of your heat-sensitive materials. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to meet your unique laboratory or industrial needs.

Whether you are drying lignin precursors or advanced organic polymers, our precision thermal solutions ensure maximum material recovery and chemical activity preservation.

Ready to optimize your drying workflow? Contact us today to find your perfect custom furnace solution.

Visual Guide

References

- Meruyert Nazhipkyzy, Dana D. Assylkhanova. Synthesis of Lignin/PAN Fibers from Sawdust. DOI: 10.3390/fib12030027

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- How does a vacuum furnace enable effective magnesium vapor collection? Master Zoned Temperature Control for High Purity

- How does the vacuum environment benefit material processing? Achieve Superior Purity and Control

- Why is a vacuum oven or drying furnace essential for catalyst reuse experiments? Ensure Reliable Recycled Catalyst Data

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components

- In which industries are vacuum sintering furnaces commonly used? Essential for High-Performance Materials

- Why is a vacuum oven utilized for g-C3N4/CdS precursor drying? Protect Nano-Architecture & Prevent Oxidation

- What combination of pumps is typically used for vacuum sintering furnaces? Boost Efficiency with Rotary Vane & Roots Pumps