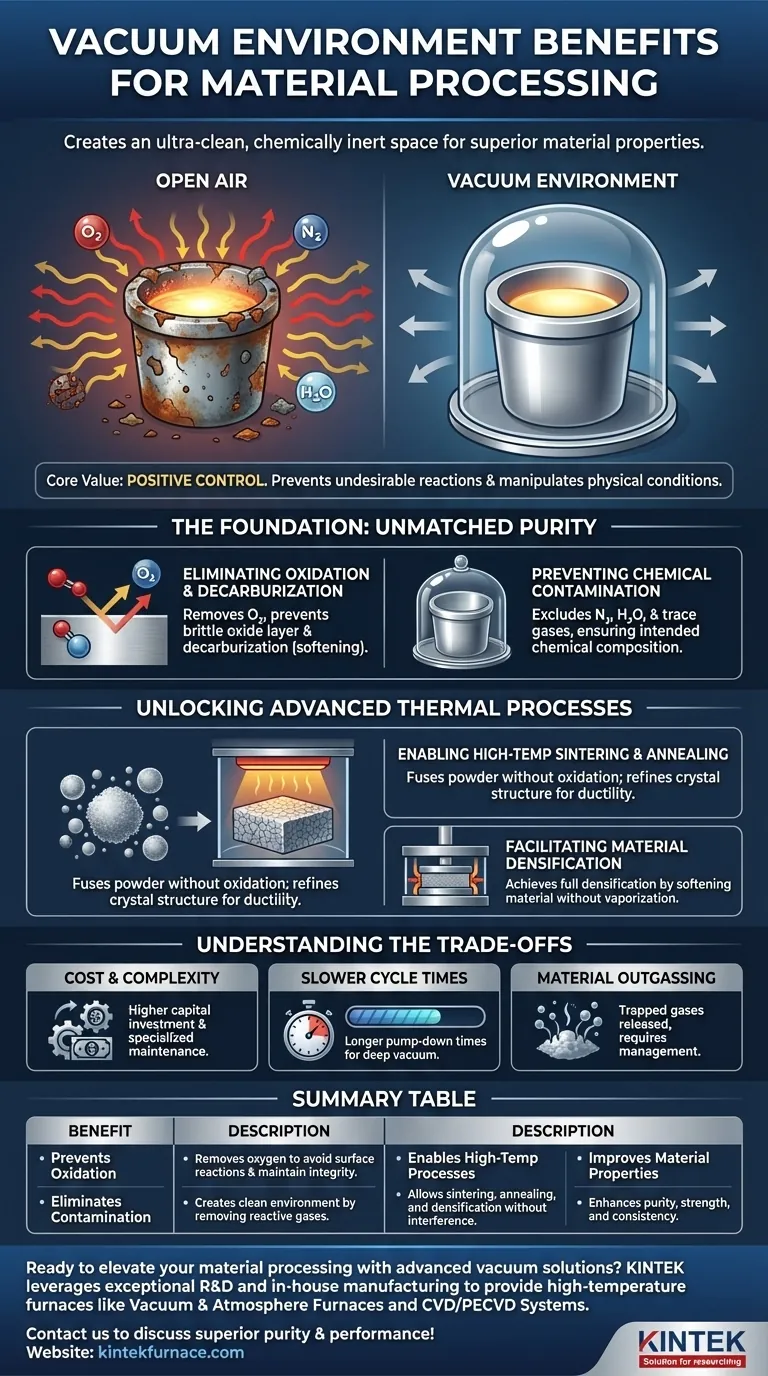

In essence, a vacuum environment benefits material processing by creating an ultra-clean, chemically inert space. By removing air and other atmospheric gases, a vacuum prevents unwanted reactions like oxidation and eliminates sources of contamination. This unparalleled control over the processing environment is critical for achieving high material purity, enhancing physical properties, and enabling high-temperature processes that would be impossible in open air.

The core value of a vacuum is not simply the absence of air, but the positive control it grants over the material's environment. This control allows engineers and scientists to prevent undesirable chemical reactions and manipulate physical conditions to produce materials with superior purity, strength, and consistency.

The Foundation: Achieving Unmatched Purity

The most immediate benefit of a vacuum is the removal of reactive gases that would otherwise compromise the material. This creates a pristine environment analogous to a sterile cleanroom for your components.

Eliminating Oxidation and Decarburization

At elevated temperatures, oxygen in the air aggressively reacts with the surface of many materials, a process called oxidation. This forms a brittle, undesirable oxide layer.

A vacuum furnace removes virtually all the oxygen, completely preventing this reaction and preserving the material's clean, metallic surface. For carbon-based alloys, it also prevents decarburization, the loss of carbon from the surface, which would otherwise soften the material.

Preventing Chemical Contamination

Air is not just oxygen. It contains nitrogen, water vapor, and other trace gases that can react with or dissolve into a material during heat treatment.

This contamination can alter the material's fundamental properties. A vacuum ensures that the only elements present are those of the material itself, guaranteeing its intended chemical composition and purity.

Unlocking Advanced Thermal Processes

Many modern material synthesis and treatment techniques are only viable in a vacuum. The absence of atmospheric pressure fundamentally changes how materials behave at high temperatures.

Enabling High-Temperature Sintering and Annealing

Sintering is a process where powdered materials are heated to fuse into a solid mass without fully melting. In open air, this would cause massive oxidation.

A vacuum provides the clean, high-temperature environment needed for sintering, creating dense, strong parts. It is also ideal for annealing, a heat treatment that refines a material's crystal structure to improve ductility and reduce internal stresses.

Facilitating Material Densification

Certain processes, like hot-pressing, use a vacuum to achieve full densification of a material. Under vacuum, a material can be heated to temperatures that would cause it to vaporize at normal atmospheric pressure.

This allows the material to soften or slightly melt, enabling applied pressure to squeeze out any remaining voids. The result is a highly dense, non-porous component with superior mechanical properties.

Understanding the Trade-offs

While powerful, vacuum processing is not a universal solution. The decision to use it requires balancing its distinct advantages against practical constraints.

The Cost and Complexity of Equipment

Vacuum furnaces and their associated pumping systems represent a significant capital investment. They also require specialized knowledge for operation and regular maintenance to ensure performance and reliability.

Slower Process Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber to the target pressure can add significant duration to the overall process cycle. This can be a throughput bottleneck in high-volume manufacturing environments.

Material Outgassing

Some materials naturally contain trapped gases that are released when placed under vacuum, a phenomenon called outgassing. This can contaminate the vacuum environment and interfere with the process, requiring careful management and potentially longer pump-down times.

Making the Right Choice for Your Goal

Selecting the right processing environment depends entirely on your end objective. A vacuum is a powerful tool when its benefits align with your specific material and performance requirements.

- If your primary focus is maximum purity and performance: A vacuum is non-negotiable for applications in aerospace, medical implants, or semiconductors where contamination can lead to catastrophic failure.

- If your primary focus is cost-effective production of complex parts: Vacuum sintering can be highly efficient, creating near-net-shape parts with excellent strength and wear resistance, minimizing waste and costly secondary machining.

- If your primary focus is research and development of novel materials: A vacuum provides the ideal, controlled environment for synthesizing new materials like nanomaterials or superconductors, ensuring purity and promoting desired crystal formation.

Ultimately, employing a vacuum gives you precise control over your material's destiny, ensuring it meets the most demanding specifications.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Removes oxygen to avoid surface reactions and maintain material integrity. |

| Eliminates Contamination | Creates a clean environment by removing reactive gases like nitrogen and water vapor. |

| Enables High-Temperature Processes | Allows sintering, annealing, and densification without atmospheric interference. |

| Improves Material Properties | Enhances purity, strength, and consistency for demanding applications. |

Ready to elevate your material processing with advanced vacuum solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs. Contact us today to discuss how we can help you achieve superior purity and performance in your lab!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability