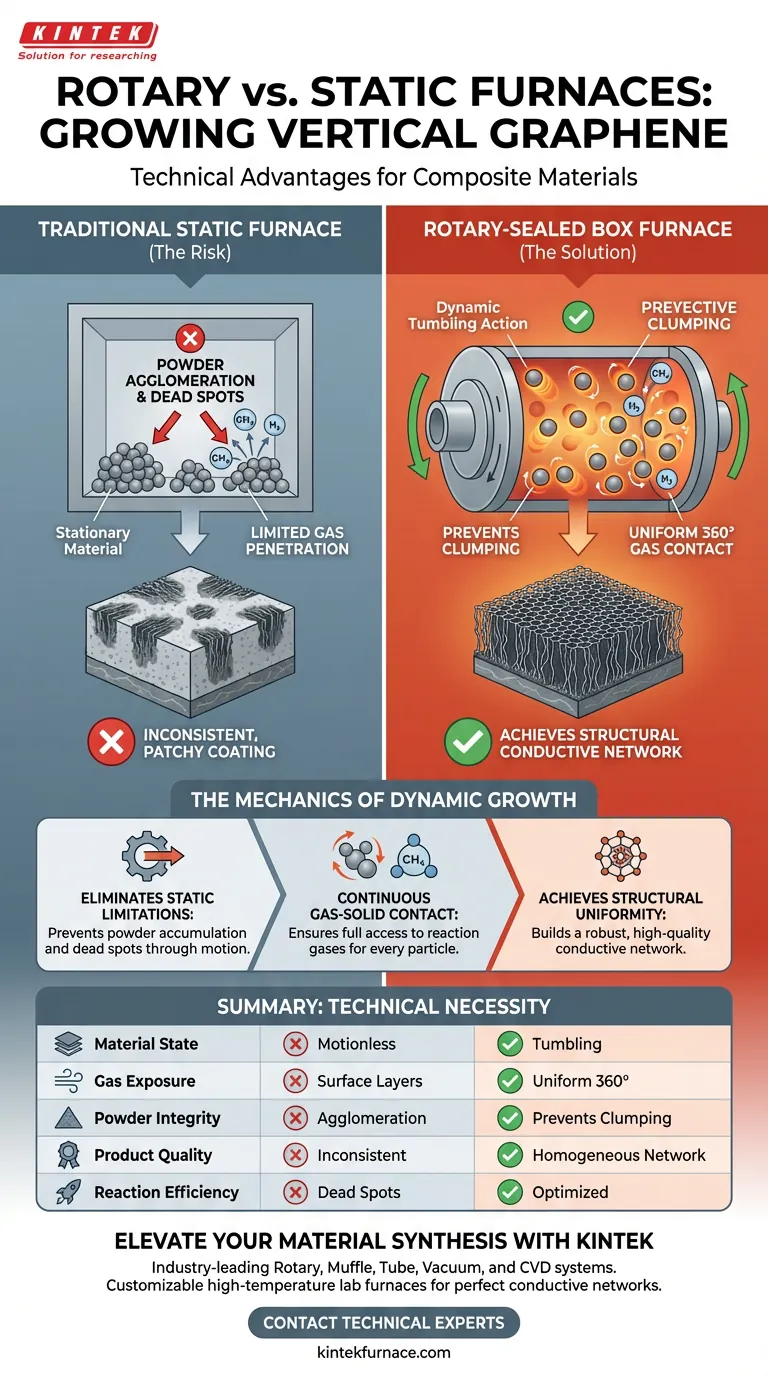

The definitive technical advantage of a rotary-sealed box furnace is the creation of a dynamic reaction environment. Unlike static furnaces, which leave materials stationary, a rotary system physically tumbles the composite base materials (such as SiNDs/C nanospheres) throughout the process. This motion ensures that the entire surface area maintains continuous, uniform contact with reaction gases like methane (CH4) and hydrogen (H2).

By utilizing a dynamic tumbling process, the rotary furnace prevents powder accumulation and eliminates dead spots. This ensures every nanosphere receives a uniform graphene coating, which is required to build a reliable, high-quality conductive network.

The Mechanics of Dynamic Growth

Eliminating Static Limitations

In a traditional static furnace, the base material remains motionless during the growth phase.

This lack of movement often leads to powder accumulation. When materials clump together, the reaction gases cannot penetrate the inner layers effectively, leading to inconsistent growth rates across the batch.

Continuous Gas-Solid Contact

The rotary-sealed box furnace solves this by introducing a tumbling action.

As the furnace rotates, the nanospheres are constantly agitated and exposed to the environment. This ensures that the reaction gases (CH4 and H2) have full access to the surface of every particle, rather than just the top layer.

Achieving Structural Uniformity

Preventing Uneven Reactions

Uniformity is the primary metric for success in growing vertical graphene (VG).

The dynamic nature of the rotary furnace prevents the uneven reactions that plague static methods. By keeping the particles in motion, the system ensures that temperature and gas concentration are distributed equally across all materials.

Building a Robust Conductive Network

The ultimate goal of this process is to create a functional composite material.

Because the rotary process coats each nanosphere individually and uniformly, the resulting vertical graphene forms a cohesive structure. This uniformity is technically necessary to establish a high-quality conductive network throughout the material, which is often impossible to achieve with patchy, static-grown coatings.

The Risks of Static Processing

When evaluating these furnace types, it is critical to understand the specific downsides of the static approach for this application.

Powder Agglomeration

Static furnaces are highly susceptible to material clumping. Without mechanical agitation, nanospheres tend to aggregate, shielding inner surfaces from the necessary chemical reactions.

Inconsistent Material Properties

The result of static processing is often a batch of material with highly variable properties. Some areas may have heavy graphene growth, while others have little to none, compromising the overall performance of the composite.

Making the Right Choice for Your Goal

To select the correct furnace configuration for your specific material requirements, consider the following:

- If your primary focus is electrical performance: Prioritize the rotary furnace to ensure the uniform conductive network required for high-efficiency electron transport.

- If your primary focus is material homogeneity: Use the rotary system to prevent powder accumulation and ensure every nanosphere is identical in coating thickness.

The rotary-sealed box furnace is not just an alternative; it is a technical necessity for achieving uniform, high-quality vertical graphene coverage on nanospheres.

Summary Table:

| Feature | Rotary-Sealed Box Furnace | Traditional Static Furnace |

|---|---|---|

| Material State | Continuous tumbling and agitation | Stationary and motionless |

| Gas Exposure | Uniform 360° gas-solid contact | Limited to surface layers |

| Powder Integrity | Prevents accumulation and clumping | Highly susceptible to agglomeration |

| Product Quality | Homogeneous conductive network | Inconsistent material properties |

| Reaction Efficiency | Optimized through dynamic motion | High risk of dead spots |

Elevate Your Material Synthesis with KINTEK

Don't let static processing limitations compromise your research. KINTEK provides industry-leading Rotary, Muffle, Tube, Vacuum, and CVD systems designed to meet the rigorous demands of advanced nanomaterial growth. Our expert R&D and manufacturing teams specialize in creating customizable high-temperature lab furnaces that ensure your materials achieve the perfect conductive network.

Ready to optimize your graphene growth process? Contact our technical experts today to find the ideal furnace solution for your unique laboratory needs.

Visual Guide

References

- Zhenwei Li, Jie Yu. Macroporous Directed and Interconnected Carbon Architectures Endow Amorphous Silicon Nanodots as Low-Strain and Fast-Charging Anode for Lithium-Ion Batteries. DOI: 10.1007/s40820-023-01308-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What types of materials are commonly processed in indirect-fired rotary kilns? Ideal for High-Purity, Sensitive Materials

- What makes rotary furnaces suitable for continuous production? Unlock High-Volume Efficiency & Uniformity

- How does multi-zone heating control benefit the rotary furnace process? Achieve Precise Thermal Profiling for Superior Results

- How does customization benefit the use of rotary kilns? Boost Efficiency and Quality with Tailored Solutions

- How does the rotary tube sintering furnace achieve high sintering efficiency? Boost Uniformity and Speed

- What are the main components of a rotary tube sintering furnace? Discover the Key Parts for Uniform Heating

- What advantages do tilting rotary furnaces offer over static models? Boost Efficiency, Safety & Quality in Your Lab

- What are the key technical features of a rotary tube sintering furnace? Achieve Uniform, Continuous Thermal Processing