At their core, rotary furnaces are suitable for continuous production because their fundamental design is built around uninterrupted material transport. The combination of a rotating tube, which constantly moves material from the feed end to the discharge end, and multi-zone thermal controls ensures that a steady flow of material can be processed uniformly without ever needing to stop the system.

The true advantage of a rotary furnace isn't just its ability to run without stopping, but how this continuous operation delivers exceptional process uniformity and efficiency, making it the definitive choice for high-volume industrial applications involving loose or bulk materials.

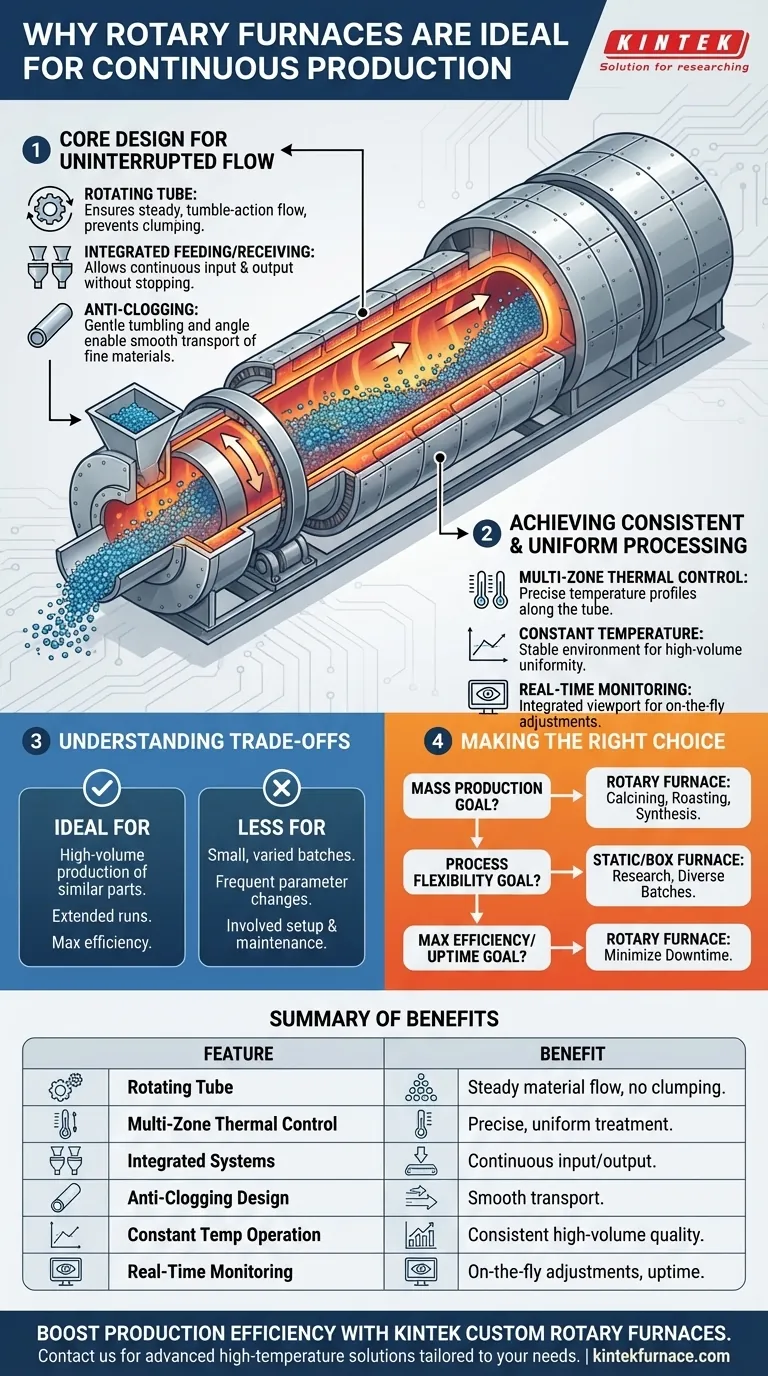

The Core Design for Uninterrupted Flow

A rotary furnace's suitability for continuous operation is not an add-on feature; it is the direct result of its mechanical and thermal architecture. Each component is engineered to facilitate a constant, controlled movement of material.

The Role of the Rotating Tube

The central element is the slowly rotating process tube. This rotation serves as the primary transport mechanism.

As the tube spins, it gently tumbles the material, preventing clumping and ensuring it flows consistently from the inlet to the outlet. This eliminates the need for batch loading and unloading cycles.

Integrated Feeding and Receiving Systems

To be truly continuous, a furnace must allow material to be added and removed while it operates.

Rotary furnaces are equipped with specialized feeding and receiving systems, such as hoppers and collection bins. These systems allow raw material to be steadily introduced and finished product to be collected without interrupting the heating process.

Anti-Clogging and Smooth Transport

Continuous flow is impossible if the material gets stuck. Furnace designs often incorporate features to prevent clogging.

The gentle tumbling action and the slight angle of the tube ensure that even fine powders or loose materials move smoothly, preventing blockages that would otherwise halt production.

Achieving Consistent and Uniform Processing

Continuous operation is only valuable if it produces a consistent, high-quality product. Rotary furnaces excel at this by creating an extremely stable processing environment.

Multi-Zone Thermal Control

The furnace tube passes through multiple, independently controlled heating zones.

This allows for a precise temperature profile to be established along the length of the tube. As material travels through, it is subjected to the exact heating and cooling sequence required for the process, ensuring every particle receives uniform treatment.

Constant Temperature for High-Volume Uniformity

Unlike batch furnaces that must cool down and heat back up, a continuous rotary furnace operates at a constant, stable temperature.

This thermal stability is critical for high-volume manufacturing, where even small variations can impact the quality of the final product. It guarantees that the thousandth kilogram of material is processed identically to the first.

Real-Time Process Monitoring

Modern rotary furnaces may include an integrated quartz viewport.

This allows operators to visually monitor the material's state in real-time during processing. Adjustments can be made on the fly without shutting down the line, further enhancing both consistency and uptime.

Understanding the Trade-offs

While powerful, a rotary furnace is a specialized tool. Its strengths in continuous processing come with specific limitations that make it unsuitable for certain applications.

Ideal for High Volume, Less for Versatility

Rotary furnaces are optimized for the high-volume production of similar parts or materials. Their efficiency comes from running the same process for extended periods.

They are not well-suited for small, varied batches or frequent changes in process parameters, as the time needed to stabilize a new temperature profile negates their primary advantage.

Initial Setup and Maintenance

The mechanical complexity of a rotating system, coupled with multi-zone heating and automated feeding systems, results in a more involved initial setup.

Maintenance can also be more demanding compared to a simpler, static batch furnace, requiring attention to motors, seals, and the drive mechanism.

Making the Right Choice for Your Process

Selecting the right furnace depends entirely on the scale and goals of your operation.

- If your primary focus is mass production: The rotary furnace's continuous flow, process uniformity, and high throughput are ideal for applications like calcining, roasting, or synthesizing large quantities of material.

- If your primary focus is process flexibility: A static tube or box furnace is better suited for research, development, or producing small, diverse batches of different materials.

- If your primary focus is maximum efficiency and uptime: The rotary furnace is unmatched for minimizing downtime and shortening production cycles in high-volume settings.

By understanding these core design principles, you can confidently determine if a rotary furnace is the right tool to achieve your industrial production goals.

Summary Table:

| Feature | Benefit for Continuous Production |

|---|---|

| Rotating Tube | Ensures steady material flow and prevents clumping for uninterrupted operation. |

| Multi-Zone Thermal Control | Provides precise temperature profiles for uniform treatment of materials. |

| Integrated Feeding/Receiving Systems | Allows continuous input and output without stopping the furnace. |

| Anti-Clogging Design | Maintains smooth transport of fine powders and loose materials. |

| Constant Temperature Operation | Guarantees consistent quality in high-volume manufacturing. |

| Real-Time Monitoring | Enables on-the-fly adjustments to enhance process consistency and uptime. |

Ready to boost your production efficiency with a custom rotary furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and industrial requirements. Contact us today to discuss how our solutions can enhance your continuous production processes and deliver superior results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control