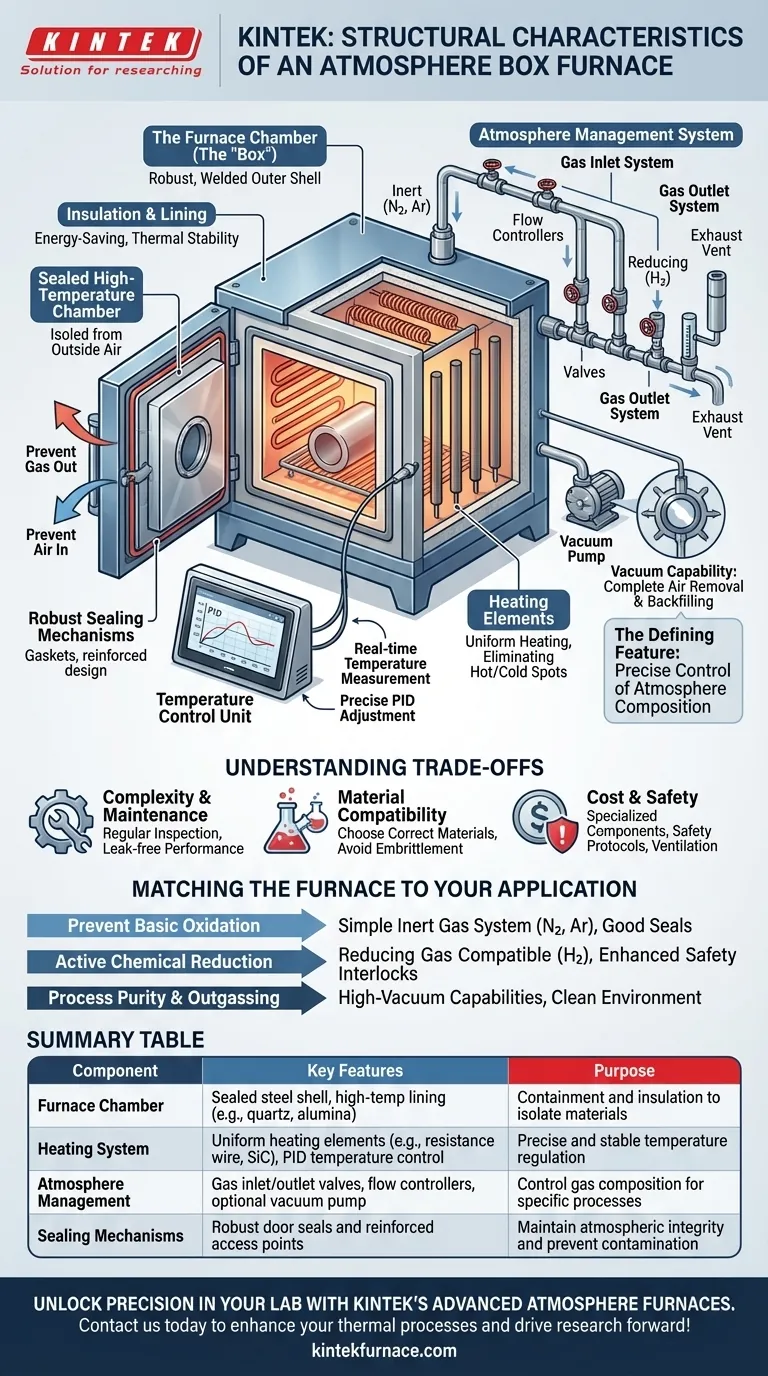

At its core, an atmosphere box furnace is defined by three integrated systems: a sealed, high-temperature chamber, a precise heating system, and a dedicated atmosphere management system. These components work in unison to create a tightly controlled environment, isolating the heated material from unwanted reactions with the outside air.

The fundamental difference between a standard furnace and an atmosphere furnace is not just the parts, but their purpose. The entire structure of an atmosphere furnace is engineered around one goal: achieving and maintaining perfect atmospheric integrity inside the chamber.

The Core Furnace Structure: Containment and Insulation

The physical body of the furnace is the first line of defense, responsible for thermal insulation and structural integrity.

The Furnace Chamber (The "Box")

The central chamber is the primary container for your workpiece. It is typically constructed from welded steel plate for the outer shell.

Inside, the chamber is lined with high-temperature-resistant materials. The specific material, such as quartz, alumina, or specialized refractory bricks, is chosen based on the furnace's maximum temperature and chemical compatibility requirements.

Insulation and Lining

Between the inner chamber and the outer shell lies a critical layer of insulation. Modern furnaces often use an energy-saving composite lining.

This insulation minimizes heat loss, which improves energy efficiency and ensures the temperature inside the chamber remains stable and uniform.

The Critical Role of Sealing

This is what truly separates an atmosphere furnace from a standard one. The furnace door and any other access points are equipped with robust sealing mechanisms.

These seals, often combined with a strengthened door design, are crucial for preventing gas from leaking out and, more importantly, preventing air from leaking in and contaminating the process.

The Heating and Temperature Control System: Achieving Precision

This system is responsible for generating and regulating the heat required for the process with a high degree of accuracy.

Heating Elements

Heating elements generate the thermal energy. They are typically made from materials like high-temperature resistance wire or silicon carbide (SiC) rods.

These elements are strategically arranged around the chamber to provide uniform heating, eliminating hot or cold spots that could compromise the process outcome.

Temperature Control Unit

The temperature control system is the brain of the furnace. It uses thermocouples placed inside the chamber to measure the temperature in real time.

This data is fed to a programmable controller, often using a PID (Proportional-Integral-Derivative) algorithm, which precisely adjusts the power sent to the heating elements to follow a pre-set temperature profile. Advanced models feature touchscreen interfaces and safety alarms.

The Atmosphere Management System: The Defining Feature

This system is what gives the furnace its name. It introduces, maintains, and removes the specific gases required for the material processing.

Gas Inlet and Outlet Systems

The furnace is equipped with dedicated gas inlet and outlet pipes and valves. These ports allow for the controlled introduction of specific gases, such as inert gases (Nitrogen, Argon) or reducing gases (Hydrogen).

The outlet system, often connected to a flow meter or exhaust, allows for the safe venting of the process gas.

Atmosphere Control and Flow

A dedicated control system manages the flow and mixture of gases. This allows an operator to precisely regulate the composition of the atmosphere inside the chamber.

This control is essential for processes that require a specific ratio of gases or a phased introduction of different atmospheres during the heating cycle.

Vacuum Capability

Many advanced atmosphere furnaces also include a vacuum pump. The ability to create a vacuum allows for the complete removal of air and other contaminants before backfilling the chamber with a high-purity process gas.

Understanding the Trade-offs

While powerful, the specialized structure of an atmosphere furnace introduces complexities that require careful consideration.

Complexity and Maintenance

The addition of gas lines, flow controllers, and advanced sealing mechanisms increases the furnace's complexity. These systems require regular inspection and maintenance to ensure leak-free performance.

Material Compatibility

The choice of chamber, refractory, and seal materials is critical. Certain process gases, like hydrogen, can be reactive or cause embrittlement in incompatible metals at high temperatures, leading to premature failure.

Cost and Safety

The specialized components and safety interlocks required for handling flammable or reactive gases make atmosphere furnaces more expensive than standard models. Proper safety protocols and ventilation are non-negotiable.

Matching the Furnace to Your Application

The right structural configuration depends entirely on your specific process goal.

- If your primary focus is preventing basic oxidation: A furnace with a simple inert gas system (Nitrogen or Argon) and good-quality seals is sufficient.

- If your primary focus is active chemical reduction: You need a furnace built with materials compatible with reducing gases (e.g., hydrogen) and equipped with enhanced safety interlocks.

- If your primary focus is process purity and outgassing: A furnace with high-vacuum capabilities is the correct choice to ensure a completely clean starting environment.

Ultimately, understanding how each structural component contributes to atmospheric control empowers you to select a furnace that will deliver a reliable and repeatable result.

Summary Table:

| Component | Key Features | Purpose |

|---|---|---|

| Furnace Chamber | Sealed steel shell, high-temperature lining (e.g., quartz, alumina) | Containment and insulation to isolate materials |

| Heating System | Uniform heating elements (e.g., resistance wire, SiC), PID temperature control | Precise and stable temperature regulation |

| Atmosphere Management | Gas inlet/outlet valves, flow controllers, optional vacuum pump | Control gas composition for specific processes |

| Sealing Mechanisms | Robust door seals and reinforced access points | Maintain atmospheric integrity and prevent contamination |

Unlock Precision in Your Lab with KINTEK's Advanced Atmosphere Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Whether you require inert gas handling, chemical reduction, or high-vacuum purity, our furnaces ensure reliable, repeatable results. Contact us today to discuss how we can enhance your thermal processes and drive your research forward!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage