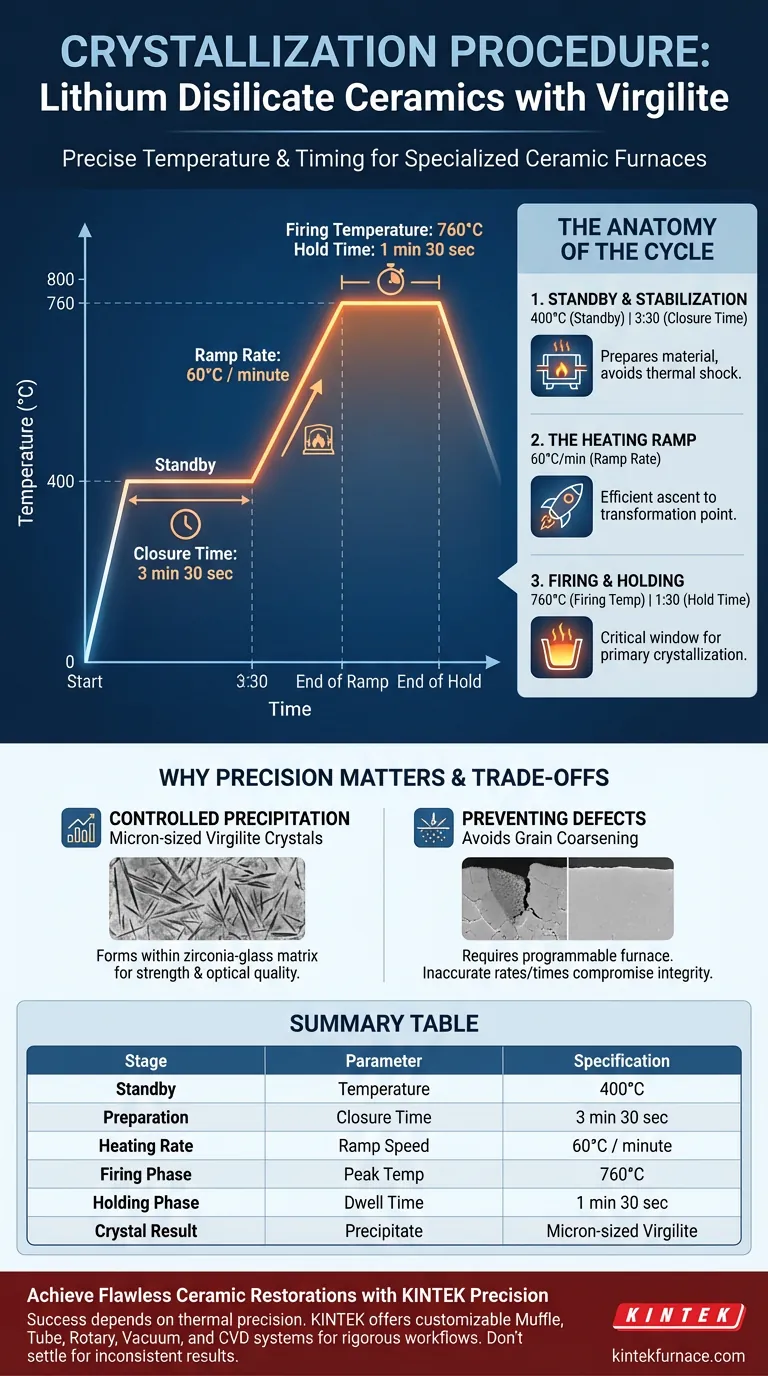

To achieve the correct crystallization of lithium disilicate ceramics containing virgilite, you must adhere to a strict thermal profile in a specialized ceramic furnace. Start with a standby temperature of 400°C and a closure time of 3 minutes and 30 seconds. Ramp the temperature up at a rate of 60°C per minute until reaching a firing temperature of 760°C, holding that peak heat for exactly 1 minute and 30 seconds.

Success relies on a controlled thermal cycle that precipitates micron-sized virgilite crystals within the zirconia-glass matrix. This specific profile significantly reduces total crystallization time while ensuring the uniform microstructure necessary for mechanical strength and optical quality.

The Anatomy of the Thermal Cycle

Standby and Stabilization

The process begins with the furnace set to a standby temperature of 400°C.

Before the active heating phase begins, there is a mandatory closure time of 3 minutes and 30 seconds. This period stabilizes the environment, preparing the material for the rapid temperature increase.

The Heating Ramp

Once stabilization is complete, the temperature must be increased at a precise rate of 60°C per minute.

This controlled ascent is faster than many traditional methods but is essential for this specific material composition. It moves the ceramic efficiently toward its transformation point without causing thermal shock.

Firing and Holding

The target firing temperature for this procedure is 760°C.

Once this temperature is reached, the material must be held there for 1 minute and 30 seconds. This specific hold time is the critical window where the primary crystallization occurs.

Why Precision Matters for Virgilite

Controlled Crystal Precipitation

The thermal profile described above is engineered to precipitate micron-sized needle-like and plate-like virgilite crystals.

These crystals form directly within the zirconia-glass matrix. This internal architecture is what defines the material's final physical properties.

Preventing Microstructural Defects

Using a programmable furnace allows you to manage the thermodynamic environment with high precision.

This regulation prevents grain coarsening, which can occur if the temperature overshoots or if the hold time is extended unnecessarily. A fine-grained microstructure is required to achieve the balance of high mechanical strength and translucent optical properties.

Understanding the Trade-offs

Equipment Limitations

You cannot achieve this specific crystallization profile without a programmable temperature control muffle furnace.

Standard furnaces lacking precise ramp-rate control may fail to hit the 60°C/minute target. Inaccurate heating rates can lead to uneven crystallization, compromising the structural integrity of the ceramic.

Speed vs. Stability

While this procedure offers a reduced total crystallization time compared to traditional methods, the specific hold time of 1:30 is non-negotiable.

Attempting to shorten this hold time further to save production minutes will result in incomplete precipitation. This leads to a weaker matrix and poor optical aesthetics.

Ensuring Process Reliability

To replicate these results consistently, ensure your equipment is calibrated to these exact specifications.

- If your primary focus is Production Efficiency: Adhere strictly to the 60°C/min ramp rate to minimize cycle time without sacrificing the integrity of the crystal formation.

- If your primary focus is Material Durability: Verify the furnace maintains the 760°C temperature without fluctuation during the 1:30 hold time to guarantee full virgilite precipitation.

Precision in these settings is the singular difference between a durable, translucent restoration and a structural failure.

Summary Table:

| Stage | Parameter | Specification |

|---|---|---|

| Standby | Temperature | 400°C |

| Preparation | Closure Time | 3 min 30 sec |

| Heating Rate | Ramp Speed | 60°C / minute |

| Firing Phase | Peak Temperature | 760°C |

| Holding Phase | Dwell Time | 1 min 30 sec |

| Crystal Result | Precipitate Type | Micron-sized Virgilite |

Achieve Flawless Ceramic Restorations with KINTEK Precision

Success in lithium disilicate crystallization depends entirely on thermal precision. At KINTEK, we understand that even a minor temperature fluctuation can compromise the mechanical strength and translucency of your materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet the rigorous 60°C/min ramp rates and stable hold times your workflow demands.

Don't settle for inconsistent results. Contact our specialists today to find the high-performance furnace solution tailored to your unique laboratory needs.

Visual Guide

References

- Carlos A. Jurado, Damian J. Lee. Influence of occlusal thickness on the fracture resistance of chairside milled lithium disilicate posterior full‐coverage single‐unit prostheses containing virgilite: A comparative in vitro study. DOI: 10.1111/jopr.13870

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How are porcelain furnaces utilized in the ceramics industry? Unlock Precision in Material Transformation

- What is the primary use of a zirconia sintering furnace in the dental industry? Transform Zirconia into High-Strength Dental Restorations

- What are the limitations of zirconia dental furnaces? Higher Costs, Longer Cycles, and Specialized Use

- What is the sintering time for zirconia? From 10-Minute Speed Cycles to Multi-Hour Protocols

- What is the process for correcting open proximal contacts using ceramic add-on material? Master Precision Dental Restoration

- What types of heating elements are used in ceramic dental furnaces? Choose the Right Element for Your Dental Lab

- What are the advantages of using pressing furnaces? Achieve Precision and Efficiency in Dental Labs

- What advantages do zirconia sintering furnaces provide for dental restorations? Boost Strength, Aesthetics, and Lab Efficiency