The primary purpose of a zirconia sintering furnace in a dental laboratory is to transform soft, pre-shaped zirconia restorations into their final, high-strength state. This is achieved through a precisely controlled heating process that solidifies and densifies the material, making it durable enough for clinical use as crowns, bridges, or implant abutments.

A zirconia sintering furnace is not just an oven; it is a highly specialized piece of equipment designed to execute a specific thermal cycle. Its unique ability to reach and maintain extreme temperatures (up to 1,600°C) is what enables the transformation of zirconia from a fragile, chalk-like material into one of the strongest and most aesthetic restorative materials in modern dentistry.

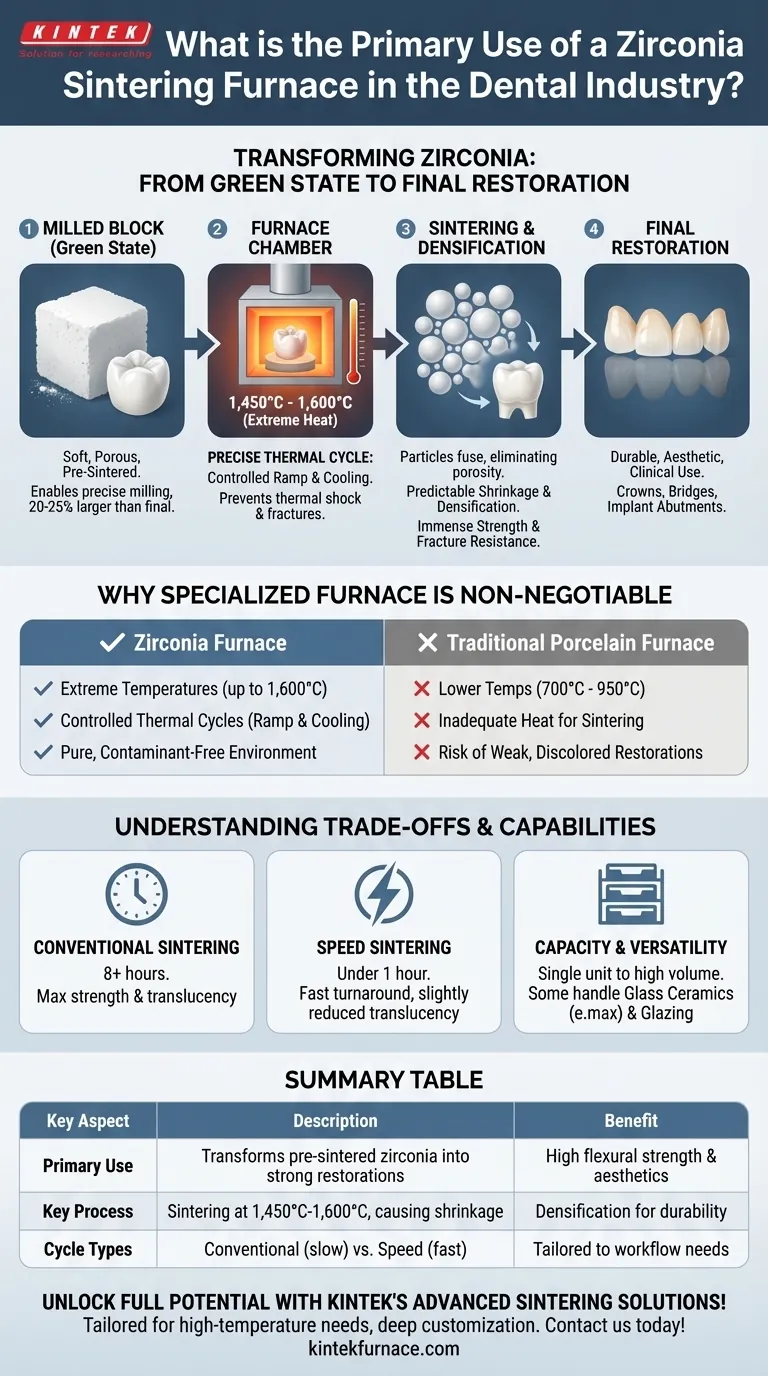

The Transformation: From Milled Block to Final Restoration

The function of the furnace is best understood as the final, critical step in the digital dentistry workflow for zirconia. The material a dental lab starts with is not the material that goes into a patient's mouth.

The "Green State" Material

Zirconia restorations are initially milled from a pre-sintered block. In this "green" or "white" state, the material is soft, porous, and chalk-like. This softness is intentional, as it allows for rapid and precise milling with minimal wear on milling burs.

The Role of Extreme Heat

Once milling is complete, the restoration is placed into the sintering furnace. The furnace slowly ramps up the temperature, often exceeding 1,450°C and sometimes reaching as high as 1,600°C. This extreme heat is far beyond the capability of a traditional porcelain oven.

The Result: Densification and Strength

At these peak temperatures, the individual zirconia particles fuse together in a process called sintering. This eliminates the porosity of the green-state material, causing the restoration to shrink by a predictable amount (typically 20-25%). The result is a process of densification that gives the final restoration its immense flexural strength and fracture resistance.

Why a Specialized Furnace is Non-Negotiable

A common point of confusion is whether any dental furnace can be used for zirconia. The answer is definitively no, and the reasons highlight the specific engineering of these devices.

Zirconia vs. Traditional Porcelain

A standard porcelain furnace is designed for firing dental ceramics and glazes at temperatures typically between 700°C and 950°C. These furnaces simply cannot generate the heat required to properly sinter zirconia. Attempting to use one would result in a weak, under-processed restoration.

The Importance of a Controlled Cycle

Sintering isn't just about reaching a peak temperature. A zirconia furnace manages the entire thermal cycle with precision, including the rate of heating (ramp rate) and the cooling phase. A cycle that is too fast can induce thermal shock, leading to micro-fractures and a compromised final product.

Preventing Contamination

The sintering chamber must be impeccably clean. Any contaminants present during the high-temperature cycle can become baked into the zirconia, causing discoloration and aesthetic failure. Dedicated zirconia furnaces are designed to maintain a pure environment for predictable, aesthetic results.

Understanding the Trade-offs and Capabilities

While all zirconia furnaces perform the same core function, their specific features create important trade-offs for a dental lab.

Conventional vs. Speed Sintering

Traditional sintering cycles can take 8 hours or longer, providing maximum strength and translucency. Newer speed-sintering furnaces can complete a cycle in under an hour for a single crown. This speed comes with a trade-off, as it may slightly reduce the final material's translucency or strength compared to a conventional cycle.

Capacity and Workflow

Furnaces vary greatly in size, from small units designed for a single crown to large, multi-level furnaces capable of sintering dozens of restorations at once. The choice depends entirely on the lab's production volume and workflow needs.

Versatility and Added Functions

Some advanced furnaces are not limited to zirconia. They may include programs for crystallizing glass ceramics (like e.max) or for running low-temperature glazing cycles. This versatility can be a significant advantage for labs looking to consolidate equipment.

Making the Right Choice for Your Goal

Selecting the right furnace depends directly on the primary objectives of the dental practice or laboratory.

- If your primary focus is maximum strength and aesthetics for complex cases: A furnace with a conventional, slow-sintering cycle is essential to achieve the best possible material properties.

- If your primary focus is rapid, same-day chairside dentistry: A dedicated speed-sintering furnace is the only way to meet the turnaround time required for a single-visit workflow.

- If your primary focus is high-volume production in a lab setting: Investing in a large-capacity furnace that can handle multiple sintering trays at once will optimize efficiency and throughput.

Ultimately, the zirconia sintering furnace is the essential gateway that unlocks the full clinical potential of this advanced dental material.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Transforms pre-sintered zirconia into strong, dense restorations like crowns and bridges |

| Key Process | Sintering at 1,450°C to 1,600°C, causing 20-25% shrinkage and densification |

| Critical Features | Precise temperature control, ramp rates, and contamination prevention |

| Cycle Types | Conventional (8+ hours for max strength) vs. Speed (under 1 hour for fast turnaround) |

| Benefits | High flexural strength, fracture resistance, and aesthetic results for dental applications |

Unlock the full potential of your dental lab with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for zirconia sintering. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental needs—whether you require maximum strength for complex cases, rapid speed for same-day dentistry, or high-volume efficiency. Contact us today to enhance your workflow with reliable, high-performance equipment!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab