At their core, ceramic dental furnaces use heating elements made from materials like Kanthal (a FeCrAl alloy), Nichrome (a NiCr alloy), or quartz tubes that encase a metallic heating wire. These elements are specifically chosen for their ability to provide precise, uniform heat within the lower temperature ranges required for firing conventional dental porcelains and ceramics.

The type of heating element used in a dental furnace is dictated entirely by its intended purpose. While standard ceramic furnaces use Kanthal or quartz for lower-temperature porcelain firing, high-temperature sintering furnaces for materials like zirconia require more robust elements like Molybdenum Disilicide (MoSi2) or Silicon Carbide (SiC).

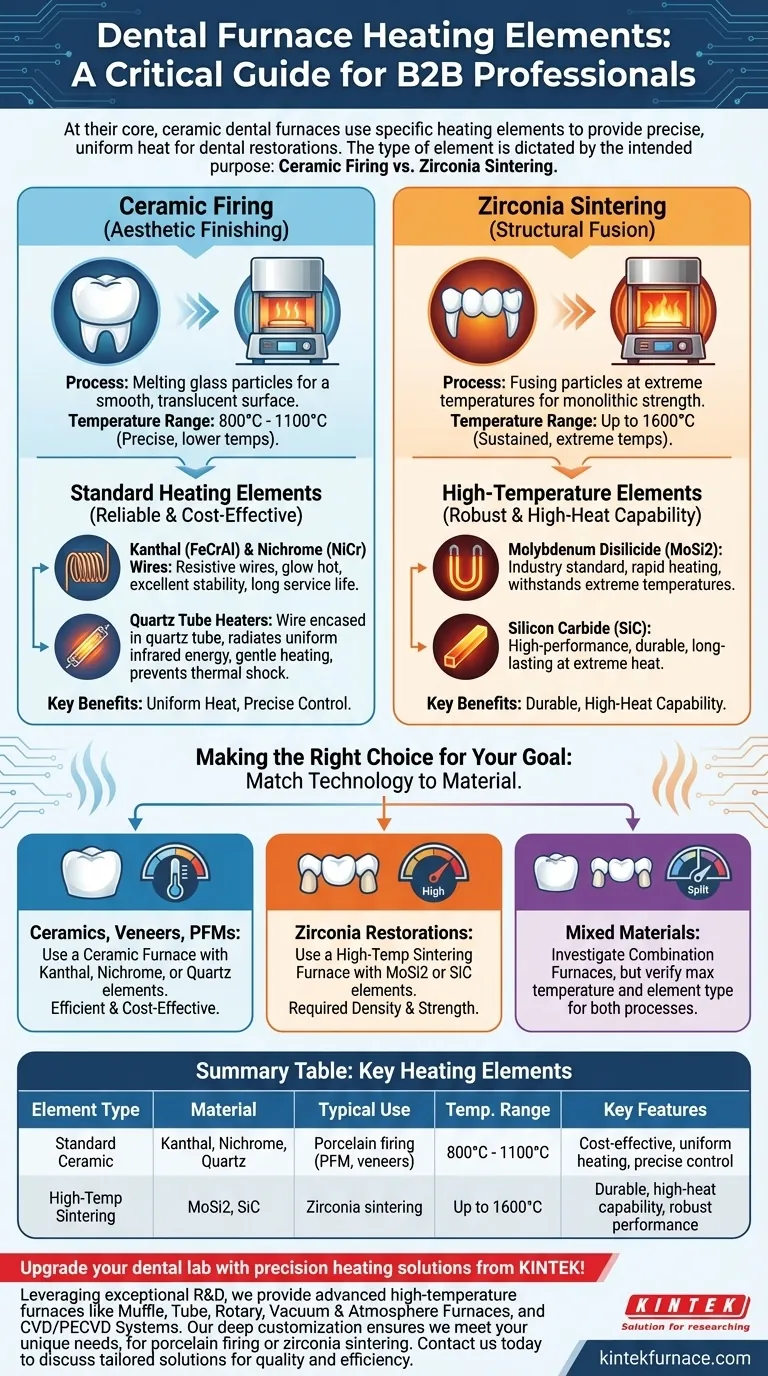

The Critical Distinction: Ceramic Firing vs. Zirconia Sintering

Understanding the heating element requires first understanding the two primary thermal processes in a dental lab: firing and sintering. They are not the same and require different equipment.

Ceramic Furnaces for Firing Porcelain

Ceramic furnaces are engineered for firing materials like porcelain-fused-to-metal (PFM) crowns, veneers, and other conventional ceramics.

The primary goal is aesthetic finishing, which involves melting glass particles to create a smooth, translucent surface. This process requires precise temperature control but at relatively lower temperatures, typically between 800°C and 1100°C.

Sintering Furnaces for Zirconia

Sintering furnaces are designed for one primary task: processing zirconia. This involves heating the material to an extremely high temperature to fuse the particles together, transforming it from a chalk-like state into a strong, monolithic restoration.

This process requires sustained temperatures that can reach up to 1600°C, far exceeding the capabilities of a standard ceramic furnace.

Heating Elements for Standard Ceramic Furnaces

Because they operate at lower temperatures, ceramic furnaces can use reliable and cost-effective heating elements.

Kanthal and Nichrome Wires

Kanthal (an iron-chromium-aluminum alloy) and Nichrome (a nickel-chromium alloy) are the workhorses of conventional ceramic furnaces. They are resistive heating wires that glow hot when electricity passes through them.

These materials offer excellent stability and a long service life within the temperature range needed for firing porcelain. They are a proven, economical choice.

Quartz Tube Heaters

Some furnaces embed the heating wire within a quartz tube. This design provides exceptionally uniform and gentle heating.

The quartz tube heats up and radiates infrared energy evenly throughout the muffle (firing chamber), which helps prevent thermal shock to the delicate ceramic and ensures flawless aesthetics.

Understanding the Trade-offs: High-Temperature Elements

The confusion between furnace types often arises because高级 materials are mentioned in the context of "dental furnaces." These are almost exclusively for sintering.

Molybdenum Disilicide (MoSi2)

MoSi2 elements are the industry standard for high-temperature zirconia sintering furnaces. They can rapidly and reliably reach the extreme temperatures needed to fully sinter zirconia.

Using these in a standard ceramic furnace would be unnecessary výkon and cost-prohibitive. They are specialized tools for a specialized, high-heat task.

Silicon Carbide (SiC)

Silicon Carbide (SiC) is another high-performance material used in sintering furnaces. It is known for its durability and longevity at extreme temperatures.

Like MoSi2, SiC is engineered资产 for the demands of sintering zirconia, not the delicate, lower-temperature work of firing conventional porcelain.

Making the Right Choice for Your Goal

The heating element is a direct indicator of the furnace's intended application. To ensure you have the right equipment, match the technology to your clinical or lab requirements.

- If your primary focus is firing conventional ceramics, veneers, and PFMs: A dedicated ceramic furnace with Kanthal, Nichrome, or quartz tube heating elements is the correct, most efficient, and cost-effective tool.

- If your primary focus is processing zirconia restorations: You must use a high-temperature sintering furnace equipped with MoSi2 or SiC heating elements to achieve the required density and strength.

- If your primary focus is handling both ceramic types and pressed ceramics: Investigate a combination furnace, but carefully verify its maximum temperature and heating elementAngry to ensure it can truly handle both the low-temp firing and high-temp sintering processes without compromise.

Ultimately, aligning the furnace's heating technology with the specific material you are processing is the key to achieving predictable, high-quality dental restorations.

Summary Table:

| Heating Element Type | Material | Typical Use | Temperature Range | Key Features |

|---|---|---|---|---|

| Standard Ceramic Furnace | Kanthal (FeCrAl), Nichrome (NiCr), Quartz Tube | Porcelain firing (PFM, veneers) | 800°C - 1100°C | Cost-effective, uniform heating, precise control |

| High-Temperature Sintering Furnace | Molybdenum Disilicide (MoSi2), Silicon Carbide (SiC) | Zirconia sintering | Up to 1600°C | Durable, high-heat capability, robust performance |

Upgrade your dental lab with precision heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, whether for porcelain firing or zirconia sintering. Contact us today to discuss how our tailored furnace solutions can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency