There is no single sintering time for zirconia. The process can range from as little as 10 minutes in a high-temperature "speed" cycle to several hours or even overnight for a conventional cycle. This variability is not arbitrary; it is a function of the specific material, the furnace technology, and the desired clinical outcome.

The optimal sintering time for zirconia is not a fixed number but a variable that must be balanced with temperature. This balance is dictated by the specific zirconia puck, the size of the restoration, and whether the primary goal is maximum strength, aesthetics, or production speed.

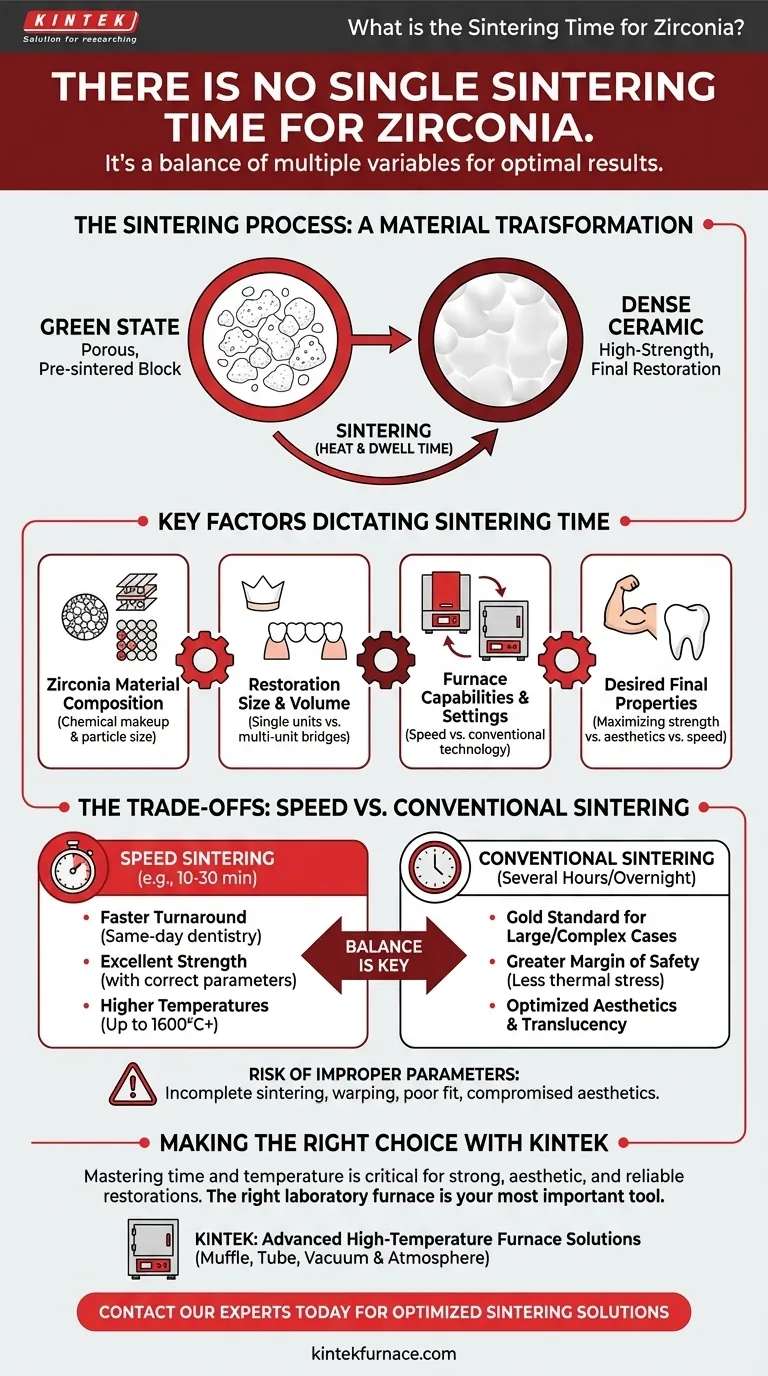

The Sintering Process: A Material Transformation

Sintering is the critical step that transforms a chalky, pre-sintered zirconia milling block—often called the "green state"—into a dense, high-strength ceramic restoration.

From "Green" to Dense

In its green state, the zirconia is composed of fine particles pressed together. Sintering uses high heat to fuse these particles, eliminating the pores between them and causing the material to shrink and densify significantly.

The Role of Heat and Dwell Time

The furnace gradually heats to a target temperature, typically between 1450°C and 1600°C. It then holds this peak temperature for a specific duration, known as the dwell time or soaking time. This is when the majority of the densification and crystallization occurs, giving the zirconia its final strength and properties.

Key Factors That Dictate Sintering Time

The ideal sintering schedule is a precise recipe determined by several interconnected variables. Changing one requires adjusting the others.

Zirconia Material Composition

Different types of zirconia (e.g., high-strength opaque vs. high-translucency anterior) have unique chemical compositions and particle sizes. Each manufacturer provides a specific, validated sintering protocol designed to optimize the properties of their material.

Restoration Size and Volume

A small, single-unit coping can be sintered much faster than a large, multi-unit bridge. Larger restorations require slower heating and cooling rates, as well as longer dwell times, to ensure heat penetrates evenly and to prevent thermal shock that can cause cracks or warping.

Furnace Capabilities and Settings

Conventional sintering furnaces require longer, multi-hour cycles. Modern "speed" furnaces are specifically designed to reach very high temperatures (up to 1600°C or more) rapidly, allowing for dramatically shortened dwell times—sometimes just a few minutes.

Desired Final Properties

The time and temperature directly influence the final grain structure of the zirconia, which in turn affects its strength and translucency. A very fast, high-temperature cycle might maximize flexural strength but could potentially impact the material's aesthetic properties. For example, one study found the highest flexural strength was achieved at a high temperature of 1580°C with a dwell time of only 10 minutes.

Understanding the Trade-offs: Speed vs. Conventional Sintering

Choosing a sintering cycle involves balancing the need for efficiency against the requirements for optimal material properties and longevity.

The Case for Speed Sintering

The primary advantage is dramatically faster turnaround, enabling same-day dentistry for single-unit restorations. When performed correctly with a compatible material and furnace, it can produce restorations with excellent strength.

The Case for Conventional Sintering

Longer cycles are generally considered the gold standard for complex or large-span cases like bridges. The slower heating and cooling provide a greater margin of safety against thermal stress, and these cycles are often what manufacturers use to validate the long-term performance and aesthetics of their materials.

The Risk of Improper Parameters

Deviating from the manufacturer's recommendations is a significant risk. Using an incorrect cycle can lead to incomplete sintering (resulting in low strength), warping, poor marginal fit, or compromised aesthetics. Always use a program specifically designed for the zirconia you are using.

Making the Right Choice for Your Goal

Always begin by consulting the manufacturer's instructions for your specific zirconia. From there, you can make an informed choice based on the clinical and production needs.

- If your primary focus is the fastest turnaround for a single crown: A speed sintering cycle in a compatible furnace may be the ideal choice, provided you use a zirconia validated for this process.

- If your primary focus is maximum predictability for a large bridge: A conventional, longer sintering cycle is the most reliable approach to ensure even densification and minimize thermal stress.

- If your primary focus is optimizing aesthetics for an anterior case: Adhere strictly to the manufacturer's recommended conventional cycle, which is fine-tuned to achieve the intended translucency and shade.

- If you are ever in doubt: Default to the standard, conventional sintering cycle provided by the zirconia manufacturer. This is the most tested and validated method.

Ultimately, mastering zirconia sintering is about understanding that time and temperature are tools to achieve a specific, desired outcome.

Summary Table:

| Factor | Impact on Sintering Time |

|---|---|

| Zirconia Material | High-translucency vs. high-strength types require different validated protocols. |

| Restoration Size | Small crowns sinter faster; large bridges need slower, longer cycles to prevent warping. |

| Furnace Type | Speed furnaces enable 10-minute cycles; conventional furnaces require multi-hour cycles. |

| Desired Outcome | Maximizing strength vs. aesthetics vs. production speed requires different time/temperature balances. |

Achieve Perfect Zirconia Sintering Results with KINTEK

Mastering the balance between time and temperature is critical for strong, aesthetic, and reliable zirconia restorations. The right laboratory furnace is your most important tool.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique sintering requirements—whether you need rapid speed cycles for same-day dentistry or conventional cycles for complex bridgework.

Let us help you optimize your sintering process. Contact our experts today to discuss your specific needs and discover the ideal furnace solution for your laboratory.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab