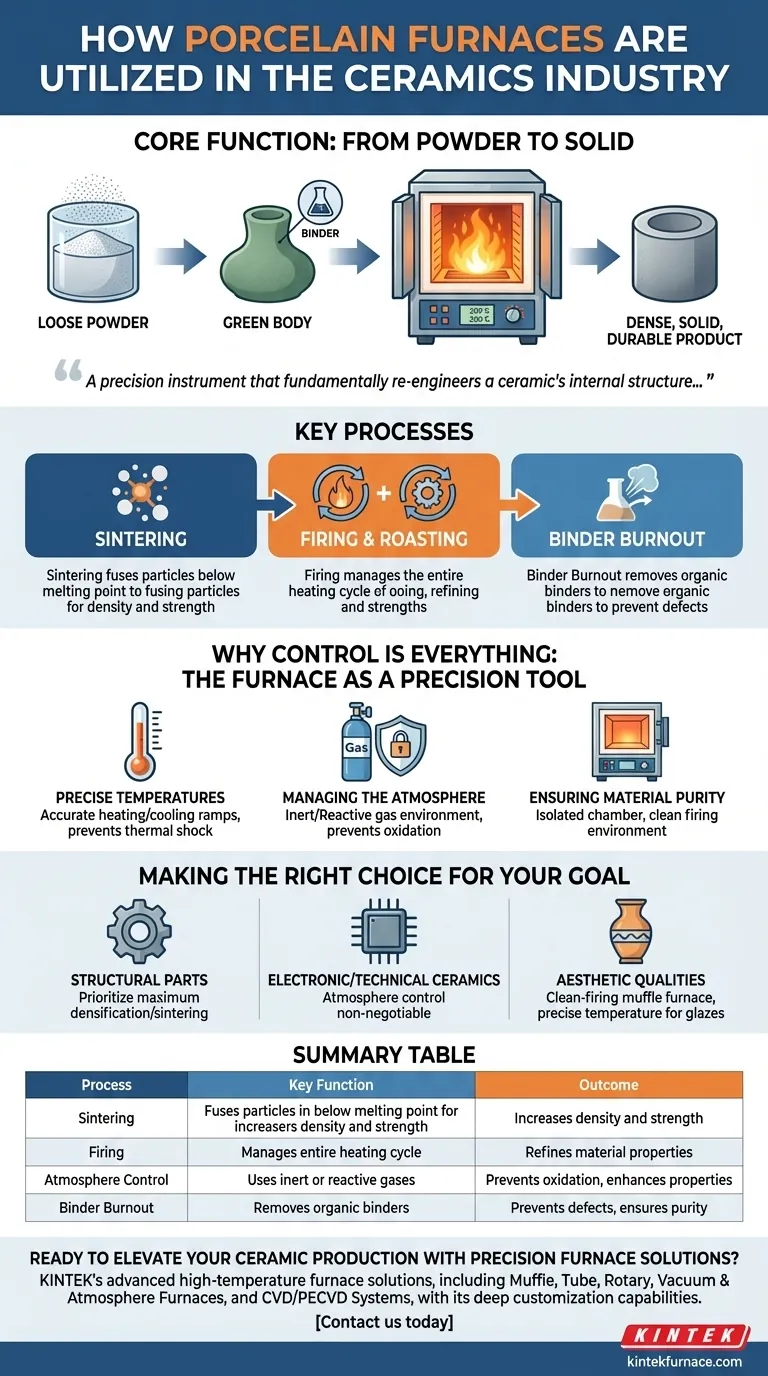

At its core, a porcelain furnace is used in the ceramics industry to transform loose or compacted powders into a dense, solid, and durable final product. This is accomplished through high-temperature thermal processes, primarily sintering and firing, which are conducted in a highly controlled environment to achieve specific mechanical, thermal, and aesthetic properties.

The essential role of a porcelain furnace is not simply to heat material, but to serve as a precision instrument that fundamentally re-engineers a ceramic's internal structure, turning raw potential into a finished component with predictable and reliable characteristics.

The Core Function: From Powder to Solid

The journey of a ceramic piece begins as a collection of fine particles, often mixed with a binder to hold a preliminary shape (known as a "green body"). The furnace is responsible for the critical transformation from this fragile state into a robust, solid object.

Sintering: The Primary Process

Sintering is the most crucial function performed in a ceramic furnace. It involves heating the compacted powder to a high temperature, but below its melting point.

At this temperature, the atoms in the particles diffuse across the boundaries of adjacent particles, fusing them together. This process reduces porosity, increases the material's density and strength, and shrinks the part to its final dimensions.

Firing and Roasting: Refining and Preparing

While often used interchangeably with sintering, firing is a broader term encompassing the entire heating cycle. This includes the initial heating ramp, a "soak" at the peak temperature, and a controlled cooling period.

Roasting is a thermal treatment often used to prepare raw powders by inducing chemical changes or removing volatile impurities before the main forming and sintering stages.

Binder Burnout: Clearing the Way for Fusion

Before sintering can occur, any organic binders used to shape the green body must be completely removed. This process, also known as binder burnout or "glue discharge," happens at lower temperatures.

If not done carefully, trapped gases from the burning binder can cause cracks or defects in the final product. The furnace must manage this stage with a slow temperature ramp and proper ventilation.

Why Control is Everything: The Furnace as a Precision Tool

A furnace is far more than a simple oven. Achieving the desired properties in modern ceramics demands exacting control over every aspect of the thermal cycle. The type of furnace used, such as a muffle or atmosphere furnace, is chosen based on the level of control required.

Achieving Precise Temperatures

Different ceramic materials require unique and highly specific temperature profiles. The furnace must execute pre-programmed heating and cooling rates (ramps) and hold specific temperatures (soaks) with extreme accuracy.

This precision prevents thermal shock, which can cause cracking, and ensures the development of the desired crystalline structure and phase transformations within the material.

Managing the Atmosphere

For many advanced ceramics, the chemical atmosphere inside the furnace is just as important as the temperature.

Atmosphere furnaces provide an oxygen-free (inert) or reactive gas environment. This is critical for preventing the oxidation of non-oxide ceramics or for promoting specific chemical reactions that enhance material properties.

Ensuring Material Purity

Contamination can ruin a ceramic component, especially in technical applications like electronics or medical implants.

Muffle furnaces are designed with an inner chamber (the muffle) that isolates the ceramic part from direct contact with heating elements or combustion byproducts. This ensures a clean firing environment and maintains material purity.

Making the Right Choice for Your Goal

The specific furnace operations you prioritize depend entirely on the intended application of the final ceramic part.

- If your primary focus is creating dense, strong structural parts: Prioritize a furnace and firing cycle that achieves maximum densification through controlled sintering.

- If your primary focus is producing advanced electronic or technical ceramics: Atmosphere control is non-negotiable to prevent oxidation and ensure the material achieves its required electrical and chemical properties.

- If your primary focus is achieving specific aesthetic qualities: A clean-firing muffle furnace with precise temperature control is essential for ensuring consistent glaze maturation and vibrant color development.

Ultimately, the furnace is the critical instrument that enables the synthesis of advanced materials, turning carefully formulated powders into high-performance engineered components.

Summary Table:

| Process | Key Function | Outcome |

|---|---|---|

| Sintering | Fuses particles below melting point | Increases density and strength |

| Firing | Manages entire heating cycle | Refines material properties |

| Atmosphere Control | Uses inert or reactive gases | Prevents oxidation, enhances properties |

| Binder Burnout | Removes organic binders | Prevents defects, ensures purity |

Ready to elevate your ceramic production with precision furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing structural parts, electronic ceramics, or aesthetic pieces, we can help you achieve superior results. Contact us today to discuss your needs and discover how our tailored furnace technologies can drive your innovations forward!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab