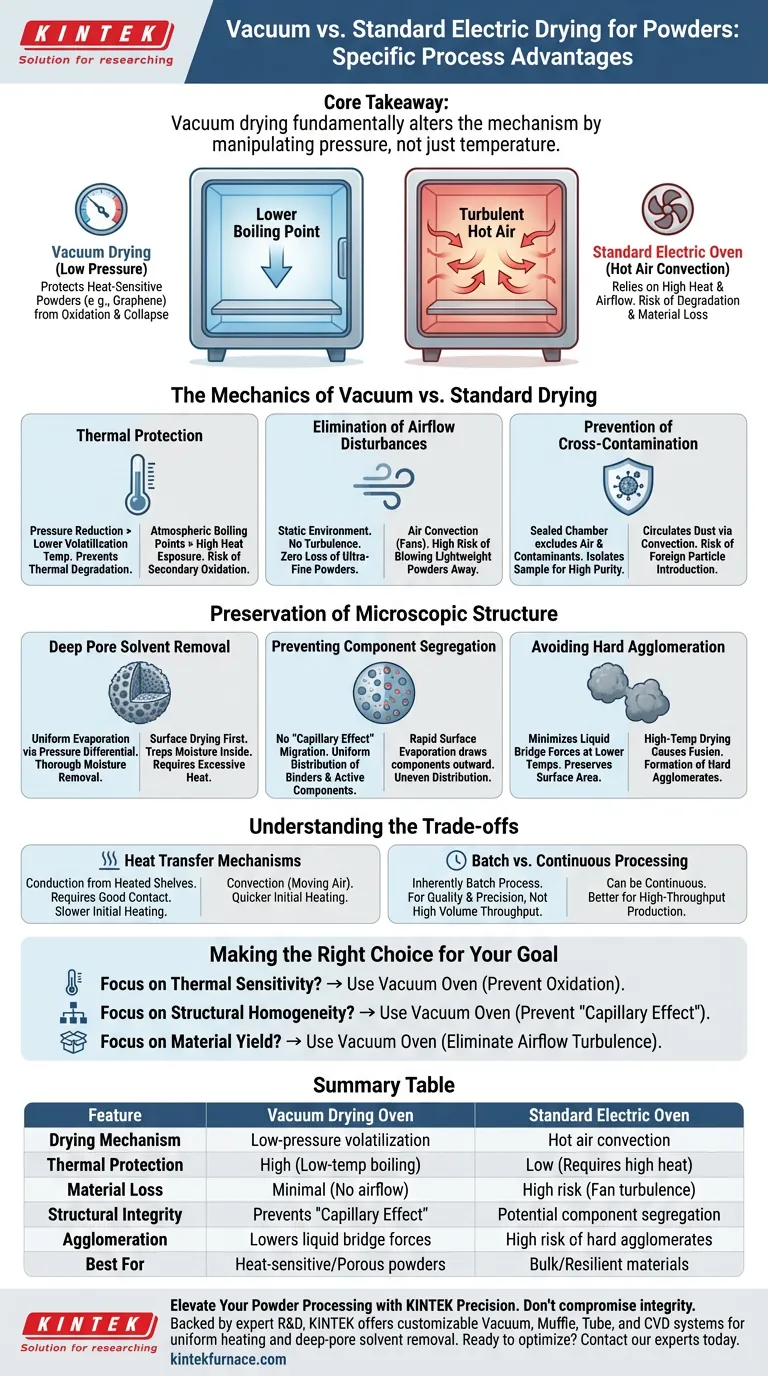

Vacuum drying fundamentally alters the drying mechanism by manipulating pressure rather than relying solely on increased temperature. While standard electric ovens depend on hot air convection which can degrade sensitive materials, vacuum ovens reduce the system pressure to lower the boiling point of solvents, enabling rapid volatilization at significantly lower temperatures.

Core Takeaway By lowering the boiling point of solvents, vacuum drying protects heat-sensitive powders from oxidation and structural collapse while eliminating the physical disruption caused by air currents. This method is superior for maintaining the microscopic integrity, chemical stability, and purity of ultra-fine or porous materials.

The Mechanics of Vacuum vs. Standard Drying

Thermal Protection Through Pressure Reduction

Standard ovens must heat solvents to their atmospheric boiling points (e.g., water at 100°C) to remove them. Vacuum ovens drastically lower this threshold.

By reducing internal pressure, solvents volatilize at much lower temperatures. This is critical for ultra-fine powders and heat-sensitive materials (such as reduced graphene or catalyst precursors), preventing thermal degradation or secondary oxidation that inevitably occurs during prolonged exposure to high heat.

Elimination of Airflow Disturbances

Standard electric ovens rely on air convection (fans) to distribute heat. This airflow creates a high risk for fine powders.

Turbulence in a standard oven can blow lightweight powders away, leading to material loss. Vacuum drying operates in a static environment, eliminating airflow disturbances and ensuring zero loss of valuable precursors.

Prevention of Cross-Contamination

Because the vacuum environment excludes air, it also removes the medium for airborne contaminants.

Standard ovens can circulate dust or foreign particles via convection currents. Vacuum drying isolates the sample, eliminating the risk of cross-contamination and preserving the high purity required for advanced applications like lithium battery anodes or ceramics.

Preservation of Microscopic Structure

Deep Pore Solvent Removal

Standard drying often dries the surface of a particle first, trapping moisture inside. Vacuum drying promotes uniform evaporation.

The pressure differential accelerates the escape of solvents from deep within porous agglomerates. This ensures thorough moisture removal without requiring excessive heat that could damage the outer shell of the particle.

Preventing Component Segregation (The Capillary Effect)

In standard drying, rapid surface evaporation can draw active components outward, leading to uneven distribution.

Vacuum drying prevents this "capillary effect" migration. By enabling low-temperature volatilization, it ensures that metal salts or binders remain uniformly distributed within the precursor or electrode slurry, rather than segregating at the surface.

Avoiding Hard Agglomeration

High-temperature drying often causes particles to fuse together due to liquid bridge forces.

By removing solvents at lower temperatures, vacuum drying minimizes these forces. This prevents the formation of hard agglomerates, preserving the powder's surface activity and specific surface area, which is vital for subsequent processing steps like sintering or densification.

Understanding the Trade-offs

Heat Transfer Mechanisms

While superior for quality, vacuum drying presents a challenge in heat transfer.

Standard ovens use convection (moving air) to heat samples quickly. Vacuum ovens, lacking air, rely on conduction from heated shelves. This means the powder container must have excellent contact with the shelf, and the initial heating phase may be slower than in a forced-air oven.

Batch vs. Continuous Processing

Vacuum drying is inherently a batch process due to the need for a sealed chamber.

If your production line requires continuous, high-throughput drying on a conveyor belt, a vacuum oven creates a bottleneck. It is a tool designed for quality and precision, not necessarily for maximum volume throughput compared to continuous tunnel ovens.

Making the Right Choice for Your Goal

To maximize process efficiency, align the drying method with your specific material requirements:

- If your primary focus is Thermal Sensitivity: Use a vacuum oven to lower solvent boiling points, preventing oxidation and preserving active surface groups on materials like graphene or metallic nanoparticles.

- If your primary focus is Structural Homogeneity: Choose vacuum drying to prevent the "capillary effect," ensuring binders and active components do not migrate to the surface of porous structures or electrode slurries.

- If your primary focus is Material Yield: Rely on vacuum drying to eliminate airflow turbulence, preventing the physical loss of ultra-fine, lightweight powders.

Summary: If your powder requires high purity, structural uniformity, or protection from heat, the vacuum oven is not just an alternative—it is a processing necessity.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Electric Oven |

|---|---|---|

| Drying Mechanism | Low-pressure volatilization | Hot air convection |

| Thermal Protection | High (Low-temp boiling) | Low (Requires high heat) |

| Material Loss | Minimal (No airflow) | High risk (Fan turbulence) |

| Structural Integrity | Prevents "Capillary Effect" | Potential component segregation |

| Agglomeration | Lowers liquid bridge forces | High risk of hard agglomerates |

| Best For | Heat-sensitive/Porous powders | Bulk/Resilient materials |

Elevate Your Powder Processing with KINTEK Precision

Don't compromise the integrity of your heat-sensitive or ultra-fine materials. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and CVD systems tailored to your specific lab requirements. Our customizable high-temperature furnaces ensure uniform heating and deep-pore solvent removal without the risk of oxidation or material loss.

Ready to optimize your drying process? Contact our experts today to find the perfect customizable solution for your research and production needs.

Visual Guide

References

- Akhtar Ali, Hijaz Ahmad. Narrowing of band gap and decrease in dielectric loss in La1-xSrxMnO3 for x = 0.0, 0.1, and 0.2 manganite nanoparticles. DOI: 10.3389/fmats.2024.1369122

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Induction Melting Furnace

People Also Ask

- Why is joint clearance important in vacuum brazing? Ensure Strong, Reliable Bonds

- Why is a closed reaction vessel necessary for the thermal reduction of graphene oxide? Unlock High-Purity rGO Synthesis

- What are the categories of vacuum sintering furnaces based on vacuum degree? Choose the Right System for Your Materials

- What factors should be considered when choosing a vacuum furnace? Optimize Your Material Processing with Expert Tips

- How does a discharge plasma sintering furnace function? Unlock Rapid, High-Temp Material Processing

- What is the core function of a vertical vacuum furnace in purifying crude magnesium? Master Precision Vacuum Distillation

- How does a vacuum heating system contribute to the resin modification? Enhance Density & Chemical Purity

- How does Reinforcement Learning (RL) optimize energy consumption? Boost Furnace Efficiency by Up to 30%