The primary function of an industrial-grade vacuum furnace during the dehydrogenation stage is to forcefully extract absorbed hydrogen from magnetic powder to restore its physical processing characteristics. Operating at temperatures between 800°C and 1000°C under high vacuum conditions (roughly 10⁻⁵ mbar), the furnace breaks the hydrogen bonds within the material. This process is essential for preparing the material for downstream recycling steps and preventing chemical degradation.

The vacuum furnace acts as a critical process control tool, removing hydrogen to restore material brittleness while strictly managing the oxygen content budget to protect reactive rare earth elements.

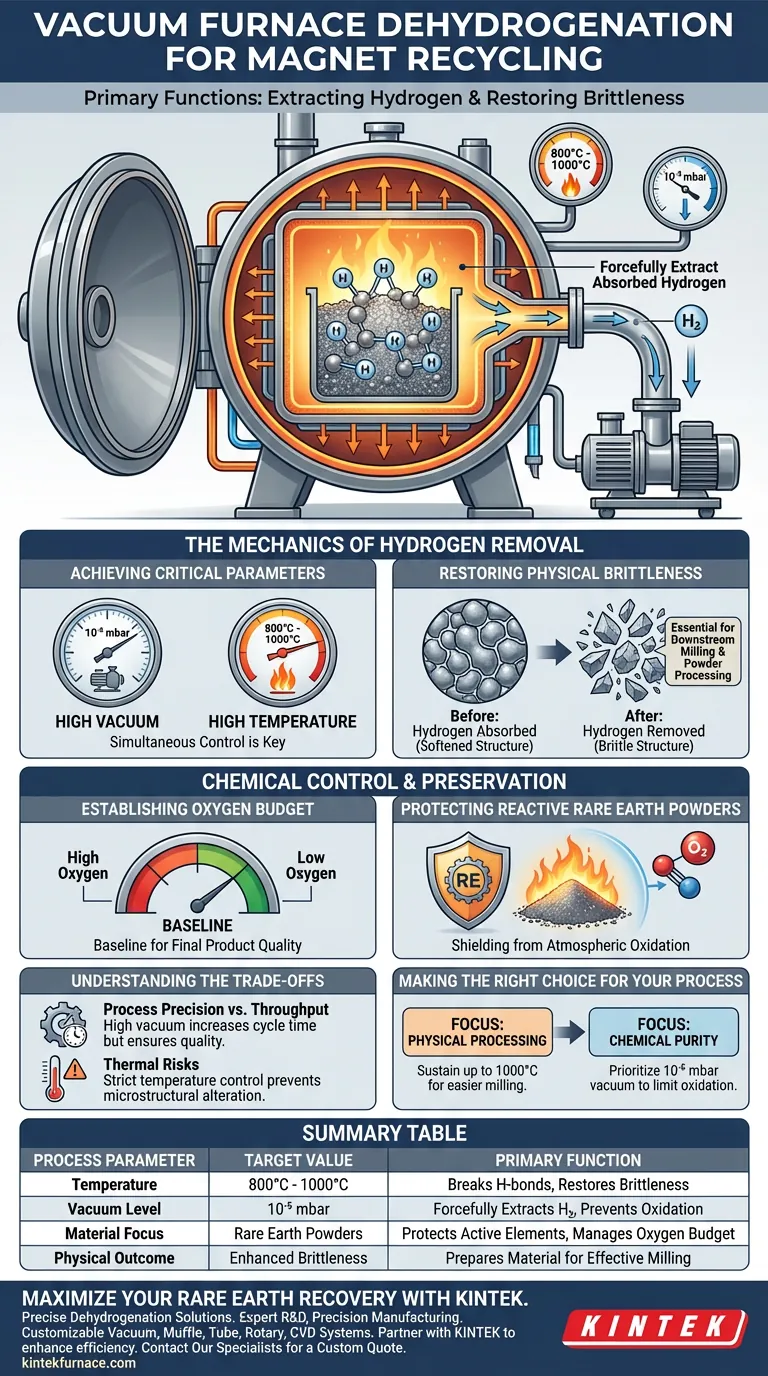

The Mechanics of Hydrogen Removal

Achieving Critical Process Parameters

To successfully dehydrogenate magnetic material, the furnace must simultaneously control two extreme variables. It must maintain a high vacuum of 10⁻⁵ mbar while sustaining temperatures between 800°C and 1000°C.

Restoring Physical Brittleness

The extraction of hydrogen is not just about chemical purity; it is about mechanical properties. Hydrogen absorption changes the physical structure of the magnet.

By removing this hydrogen, the furnace restores the material's brittleness. This return to a brittle state is a prerequisite for effective milling and powder processing in subsequent recycling stages.

Chemical Control and Preservation

Establishing the Oxygen Budget

Beyond removing hydrogen, the vacuum furnace plays a defensive role against oxidation. The process establishes a baseline for the total oxygen content budget.

This baseline is a critical metric for the quality of the final recycled product. If oxygen levels are not controlled at this stage, the magnetic performance of the recovered material will be compromised.

Protecting Active Rare Earth Powders

Rare earth materials are highly reactive and prone to rapid oxidation when heated. The vacuum environment shields these active rare earth powders from atmospheric oxygen.

This ensures that while hydrogen is being expelled, the material does not react with the environment to form unwanted oxides.

Understanding the Trade-offs

Process Precision vs. Throughput

Achieving a vacuum level of 10⁻⁵ mbar requires sophisticated pumping systems and precise seal integrity. This high standard protects the material but increases the cycle time and equipment complexity compared to lower-vacuum heat treatments.

Thermal Risks

While high heat is required for dehydrogenation, strict temperature control is vital. Fluctuations outside the 800°C to 1000°C window can fail to remove hydrogen adequately or potentially alter the microstructure of the rare earth elements in unintended ways.

Making the Right Choice for Your Process

For a recycling line to function effectively, the vacuum furnace must be tuned to specific operational goals.

- If your primary focus is Physical Processing: Ensure the furnace can sustain temperatures up to 1000°C to fully restore brittleness for easier milling.

- If your primary focus is Chemical Purity: Prioritize vacuum integrity capable of holding 10⁻⁵ mbar to strictly limit the oxidation of active rare earth powders.

Success in this stage is defined by the balance between aggressive hydrogen removal and the absolute preservation of the oxygen budget.

Summary Table:

| Process Parameter | Target Value | Primary Function |

|---|---|---|

| Temperature | 800°C - 1000°C | Breaks hydrogen bonds & restores material brittleness |

| Vacuum Level | 10⁻⁵ mbar | Forcefully extracts hydrogen while preventing oxidation |

| Material Focus | Rare Earth Powders | Protects active elements and manages oxygen budget |

| Physical Outcome | Enhanced Brittleness | Prepares material for effective milling and processing |

Maximize Your Rare Earth Recovery with KINTEK

Precise dehydrogenation is the backbone of high-quality magnet recycling. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require Vacuum, Muffle, Tube, Rotary, or CVD systems, our high-temperature furnaces are fully customizable to meet your specific vacuum integrity and thermal uniformity needs.

Don't compromise your oxygen budget or material purity. Partner with KINTEK to enhance your lab or industrial efficiency today.

→ Contact Our Specialists for a Custom Quote

Visual Guide

References

- Finks, Christopher. Technical Analysis: Magnet-to-Magnet Rare Earth Recycling Without Solvent Extraction (M2M-Δ Architecture) - Defense Supply Chain Resilience. DOI: 10.5281/zenodo.17625287

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is ammonium chloride used for depassivation in LTGN? Unlock Stainless Steel's Potential for Nitriding

- How does the vacuum pumping system perform in terms of pump down times? Achieve Faster Evacuation for Your Lab

- What are the key steps in the working principle of a vacuum furnace? Master Precision Heat Treatment for Superior Results

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What are the two main designs of vacuum furnaces? Compare Hot Wall vs Cold Wall for Your Lab

- How does the design of a vacuum furnace contribute to its energy efficiency? Maximize Thermal Performance & Reduce Costs

- How does vacuum degree affect the sintering atmosphere? Optimize Material Purity and Performance

- What materials are used for the heating elements in a vacuum furnace? Choose the Right Element for Your High-Temp Needs