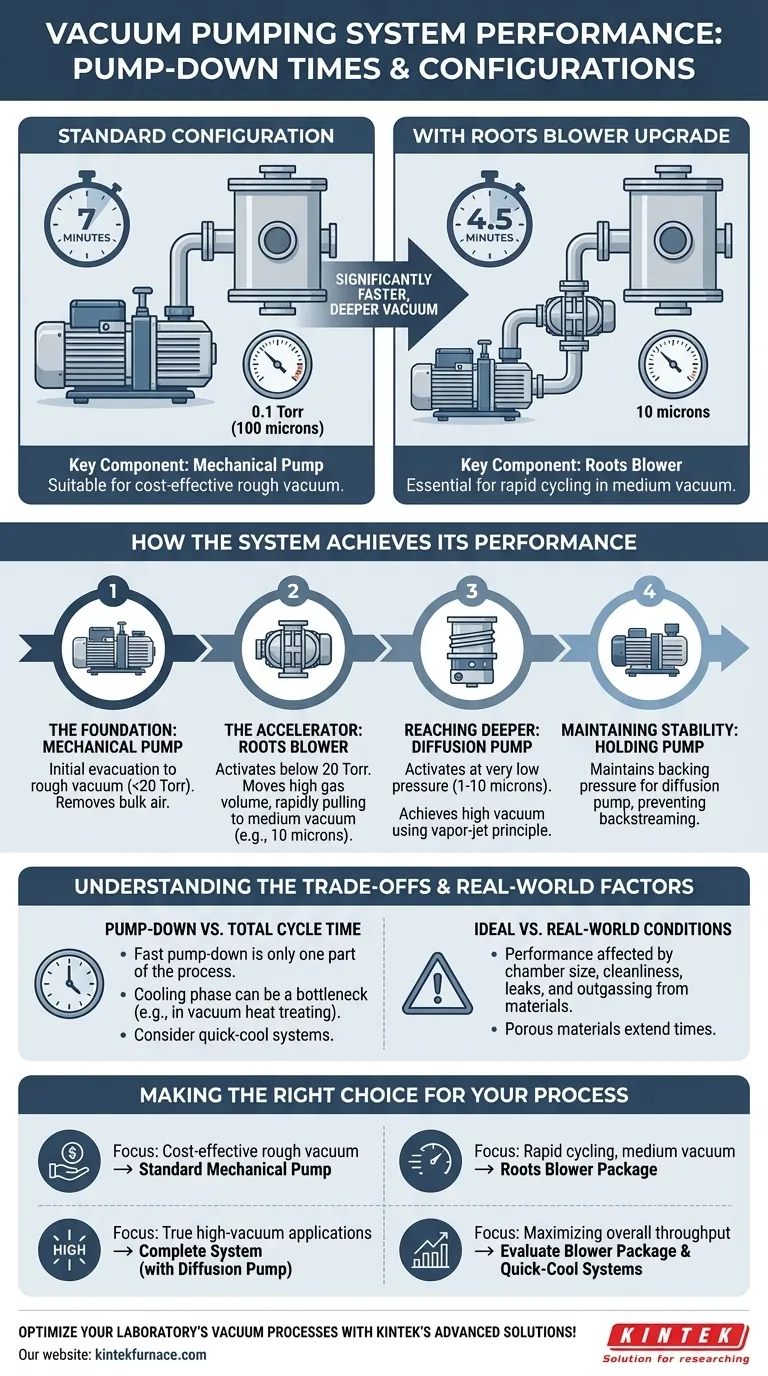

At a glance, the vacuum pumping system has a standard pump-down time of 7 minutes to reach 0.1 Torr (100 microns) with its base configuration. When upgraded with a roots blower, its performance significantly improves, reaching a deeper vacuum of 10 microns in just 4.5 minutes.

The stated pump-down times reveal a key architectural choice: the system's performance is fundamentally dependent on whether you employ the standard mechanical pump alone or supplement it with a roots blower for accelerated evacuation in the medium vacuum range.

How the System Achieves Its Performance

To understand the pump-down specifications, you must first understand how the system's components work in sequence. Each stage is designed to operate most efficiently within a specific pressure range.

The Foundation: The Mechanical Pump

The process begins with the 42.4 cfm mechanical pump. This is the workhorse of the system, responsible for the initial evacuation, or "roughing," of the chamber.

It removes the bulk of the air, taking the chamber from atmospheric pressure (760 Torr) down to the rough vacuum range, somewhere below 20 Torr.

The Accelerator: The Roots Blower

This is where the major performance gain occurs. The roots blower, a type of booster pump, does not operate at atmospheric pressure. Instead, it activates once the mechanical pump has reached its optimal range (e.g., below 20 Torr).

The blower's double-lobe impellers move a very high volume of gas, rapidly pulling the pressure from the rough vacuum level down into the medium vacuum range. This is why adding a blower reduces the time to reach 10 microns so dramatically. Options like the 10 HP, 4,200 cfm blower offer even greater acceleration.

Reaching Deeper: The Diffusion Pump

For applications requiring high vacuum, a diffusion pump takes over. This component activates at very low pressures, typically between 1 and 10 microns.

By using a vapor-jet principle with no moving parts, it can achieve pressures far beyond the capability of the mechanical and booster pumps, enabling true high-vacuum processes.

Maintaining Stability: The Holding Pump

A smaller holding pump works in concert with the diffusion pump. Its sole purpose is to maintain the correct backing pressure for the diffusion pump, preventing its oil from backstreaming into the chamber and ensuring stable high-vacuum operation.

Understanding the Trade-offs

The performance data is not just a set of numbers; it reflects critical configuration choices and their impact on your process.

Standard vs. Blower-Assisted Performance

The base system, relying only on the mechanical pump, reaches 0.1 Torr in 7 minutes. This is a respectable baseline for general-purpose applications.

Adding the roots blower creates a mechanical pump/roots blower package. This upgrade is what enables the system to reach a deeper vacuum (10 microns) in a shorter time (4.5 minutes). The trade-off is the added cost and complexity of the blower for a significant speed advantage.

Pump-Down vs. Total Cycle Time

Fast pump-down is only one part of your total process time. The inclusion of options like an inert gas quick-cool system, a gas/water heat exchanger, and 18 specialized flow channels highlights this fact.

For processes like vacuum heat treating, the cooling phase can take as long or longer than the pumping phase. A fast pump-down is of limited value if the cooling cycle creates a bottleneck. Therefore, evaluating the cooling options is just as critical as evaluating the pumps.

Ideal vs. Real-World Conditions

The specified times are benchmark figures under ideal conditions. In practice, pump-down performance will be affected by factors like the size and cleanliness of your chamber, leaks, and outgassing from the materials in your workload. Porous or uncleaned materials can release significant amounts of vapor, extending pump-down times considerably.

Making the Right Choice for Your Process

Your optimal configuration depends entirely on the demands of your specific application.

- If your primary focus is cost-effective rough vacuum: The standard mechanical pump configuration, achieving 0.1 Torr in 7 minutes, is likely sufficient for your needs.

- If your primary focus is rapid cycling in the medium vacuum range: The roots blower package is essential to achieving the speed required to reach 10 microns in 4.5 minutes.

- If your primary focus is true high-vacuum applications: You will need the complete system, including the diffusion pump stage, to operate below the 1-micron level.

- If your primary focus is maximizing overall throughput: You must evaluate both the blower package for fast pump-down and the quick-cool systems to minimize total cycle time.

Ultimately, understanding how each component contributes to the overall process allows you to configure a system that truly matches your operational goals.

Summary Table:

| Configuration | Pump-Down Time | Target Vacuum Level | Key Component |

|---|---|---|---|

| Standard | 7 minutes | 0.1 Torr (100 microns) | Mechanical Pump |

| With Roots Blower | 4.5 minutes | 10 microns | Roots Blower |

Optimize your laboratory's vacuum processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vacuum pumping system contribute to the fabrication of high-quality silicide structures? Ensure Material Purity

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- What are the stages of a vacuum furnace pumping system and how do they function? Learn the Sequential Process for High-Vacuum Efficiency

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- What materials are used for the heating elements in a vacuum furnace? Choose the Right Element for Your High-Temp Needs