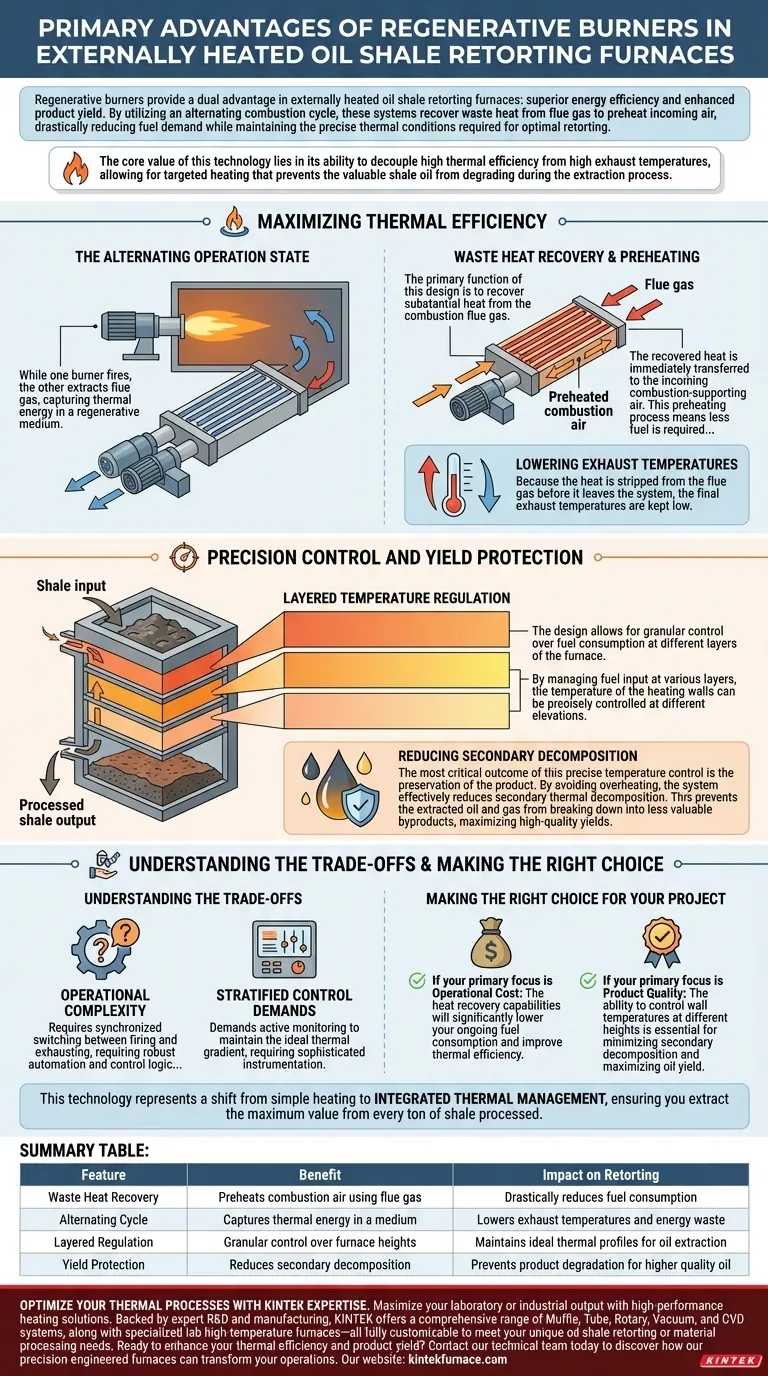

Regenerative burners provide a dual advantage in externally heated oil shale retorting furnaces: superior energy efficiency and enhanced product yield. By utilizing an alternating combustion cycle, these systems recover waste heat from flue gas to preheat incoming air, drastically reducing fuel demand while maintaining the precise thermal conditions required for optimal retorting.

The core value of this technology lies in its ability to decouple high thermal efficiency from high exhaust temperatures, allowing for targeted heating that prevents the valuable shale oil from degrading during the extraction process.

Maximizing Thermal Efficiency

The Alternating Operation State

Regenerative burners operate by alternating their states between firing and exhausting.

While one burner fires, the other extracts flue gas, capturing thermal energy in a regenerative medium.

Waste Heat Recovery

The primary function of this design is to recover substantial heat from the combustion flue gas.

Instead of venting high-temperature gas directly to the atmosphere, the system traps this energy within the furnace infrastructure.

Preheating Combustion Air

The recovered heat is immediately transferred to the incoming combustion-supporting air.

This preheating process means less fuel is required to reach the necessary operating temperature, significantly boosting overall thermal efficiency.

Lowering Exhaust Temperatures

Because the heat is stripped from the flue gas before it leaves the system, the final exhaust temperatures are kept low.

This reduces the thermal footprint of the operation and minimizes energy waste.

Precision Control and Yield Protection

Layered Temperature Regulation

The design allows for granular control over fuel consumption at different layers of the furnace.

Operators can adjust the heat input at specific heights, creating a tailored thermal profile across the vertical span of the retort.

Controlling Heating Wall Temperatures

By managing fuel input at various layers, the temperature of the heating walls can be precisely controlled at different elevations.

This ensures that the oil shale is subjected to the exact temperature required for retorting at every stage of its movement through the furnace.

Reducing Secondary Decomposition

The most critical outcome of this precise temperature control is the preservation of the product.

By avoiding overheating, the system effectively reduces secondary thermal decomposition. This prevents the extracted oil and gas from breaking down into less valuable byproducts, maximizing high-quality yields.

Understanding the Trade-offs

Operational Complexity

While regenerative burners offer superior efficiency, the requirement for "alternating operating states" introduces mechanical complexity.

The system relies on synchronized switching between firing and exhausting, which requires robust automation and control logic compared to static burner systems.

Stratified Control Demands

The ability to control temperatures at different heights is a powerful feature, but it demands active monitoring.

Operators must carefully manage the fuel consumption in each layer to maintain the ideal thermal gradient, requiring sophisticated instrumentation.

Making the Right Choice for Your Project

Regenerative burners are not just heaters; they are process optimization tools. To decide if they fit your design requirements, consider your primary operational drivers.

- If your primary focus is Operational Cost: The heat recovery capabilities will significantly lower your ongoing fuel consumption and improve thermal efficiency.

- If your primary focus is Product Quality: The ability to control wall temperatures at different heights is essential for minimizing secondary decomposition and maximizing oil yield.

This technology represents a shift from simple heating to integrated thermal management, ensuring you extract the maximum value from every ton of shale processed.

Summary Table:

| Feature | Benefit | Impact on Retorting |

|---|---|---|

| Waste Heat Recovery | Preheats combustion air using flue gas | Drastically reduces fuel consumption |

| Alternating Cycle | Captures thermal energy in a medium | Lowers exhaust temperatures and energy waste |

| Layered Regulation | Granular control over furnace heights | Maintains ideal thermal profiles for oil extraction |

| Yield Protection | Reduces secondary decomposition | Prevents product degradation for higher quality oil |

Optimize Your Thermal Processes with KINTEK Expertise

Maximize your laboratory or industrial output with high-performance heating solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temperature furnaces—all fully customizable to meet your unique oil shale retorting or material processing needs.

Ready to enhance your thermal efficiency and product yield? Contact our technical team today to discover how our precision-engineered furnaces can transform your operations.

Visual Guide

References

- Lixin Zhao, Luwei Pan. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. DOI: 10.3390/sym17071055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Where are H Type Silicon Carbide Heating Elements commonly used? Ideal for High-Temp Cycling in Glass, Electronics, and Chemicals

- What role do high temperature heating elements play in modern manufacturing processes? Unlock Precision and Quality in Material Production

- What are the primary advantages of Molybdenum Disilicide (MoSi2) heating elements? Unmatched High-Temp Performance & Lifespan

- How can the power input to a furnace be maintained as SiC resistors age? Ensure Consistent Heating with Adaptive Power Control

- What are precious metals used as high-temperature heating elements? Essential for Extreme Heat Applications

- What are the benefits of graphite heating elements in terms of longevity and performance? Unlock Unmatched Reliability and Speed

- What properties should a material have to be suitable for heating elements? Key Traits for High-Temperature Performance

- What are the basic types of heating elements based on the materials used? Choose the Right Material for Your Heating Needs