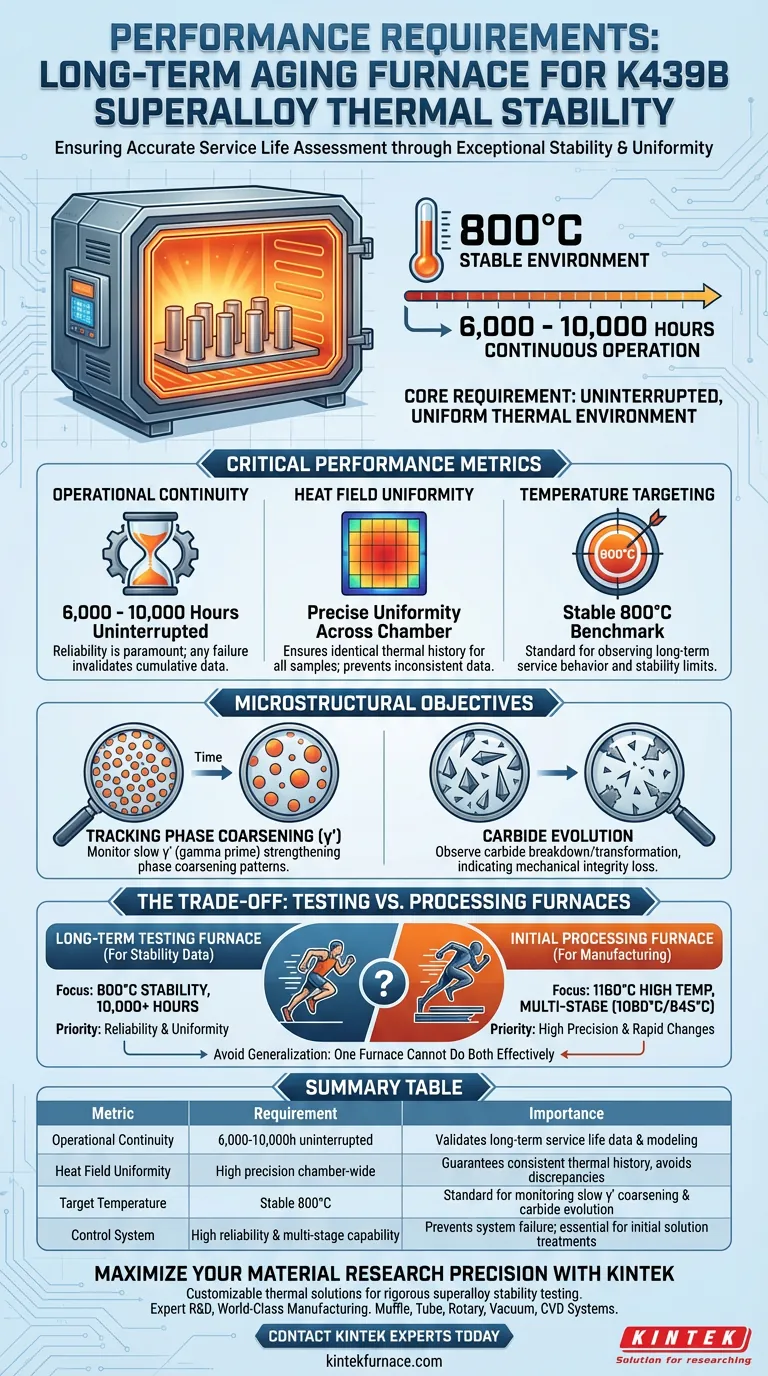

To properly evaluate the thermal exposure stability of the K439B superalloy, a long-term aging furnace requires exceptional continuous operational stability and heat field uniformity. Specifically, the equipment must be capable of maintaining a precise 800°C environment without interruption for test durations ranging from 6,000 to 10,000 hours.

Core Takeaway The validity of long-term stability data relies entirely on the furnace's ability to provide an uninterrupted, uniform thermal environment. Any fluctuation or failure during the 6,000 to 10,000-hour cycle compromises the observation of the slow coarsening patterns of the γ' phase, rendering the service life assessment inaccurate.

The Critical Performance Metrics

Operational Continuity

The defining characteristic of a furnace used for this specific application is endurance. The study of thermal exposure stability is not a short-term process; it requires uninterrupted thermal exposure experiments.

The furnace must operate continuously for 6,000 to 10,000 hours. This places a heavy emphasis on the reliability of the heating elements and control systems, as a failure at hour 5,000 would invalidate the cumulative data regarding the material's degradation.

Heat Field Uniformity

Maintaining a target temperature of 800°C is necessary, but maintaining it uniformly across the entire chamber is critical.

The furnace must ensure that every sample within the batch experiences the exact same thermal history. Without exceptional heat field uniformity, different samples might exhibit varying rates of degradation, leading to inconsistent data regarding the alloy's stability.

Temperature Targeting

For the specific study of K439B thermal stability, the furnace must hold a stable 800°C environment.

While the alloy undergoes processing at much higher temperatures (up to 1160°C for solution treatment), the 800°C benchmark is the standard for observing long-term service behavior and stability limits.

The Microstructural Objectives

Tracking Phase Coarsening

The primary goal of these high-performance furnace requirements is to enable the accurate observation of microstructural changes.

Researchers need a stable environment to monitor the slow coarsening patterns of the γ' (gamma prime) strengthening phase. If the temperature fluctuates, the rate of coarsening changes, making it impossible to model the material's real-world lifespan accurately.

Carbide Evolution

In addition to the γ' phase, the furnace must facilitate the study of carbide evolution.

The breakdown or transformation of carbides over thousands of hours is a key indicator of when the alloy will lose its mechanical integrity. Only a highly stable thermal environment can simulate the conditions necessary to trigger and track these subtle chemical changes.

Understanding the Trade-offs: Testing vs. Processing

It is vital to distinguish between a furnace used for long-term testing and one used for initial processing, as their requirements differ.

The Pitfall of Generalization

A common mistake is assuming one furnace can ideally perform all tasks. While the testing furnace focuses on 800°C stability for thousands of hours, a processing furnace for K439B has different priorities.

Processing Requirements

Processing furnaces (solution treatment and standard aging) require higher temperatures and multi-stage control:

- Solution Treatment: Requires 1160°C for short durations (4 hours) to dissolve strengthening phases and eliminate segregation.

- Controlled Aging: Requires precise multi-stage capabilities (1080°C and 845°C) to regulate the size and volume of the γ' phase.

The Trade-off

A furnace optimized for the rapid temperature changes and high heat of processing may not have the longevity or stability required for the 10,000-hour testing cycle. Conversely, a long-term aging furnace may lack the thermal power to reach the 1160°C required for solution treatment.

Making the Right Choice for Your Goal

To select the correct equipment, you must clarify the specific stage of the material lifecycle you are addressing.

- If your primary focus is determining service life: Prioritize a furnace with proven reliability for 10,000+ hour continuous cycles and high uniformity at 800°C.

- If your primary focus is material manufacturing: Prioritize a high-precision furnace capable of reaching 1160°C and executing multi-stage programs (1080°C/845°C) to optimize creep resistance.

Ultimately, for thermal stability studies, the furnace is not just a heat source; it is the time-lapse mechanism that reveals the inevitable degradation of the material.

Summary Table:

| Metric | Performance Requirement | Importance for K439B Study |

|---|---|---|

| Operational Continuity | 6,000 - 10,000 hours uninterrupted | Ensures validity of long-term service life data and material degradation modeling. |

| Heat Field Uniformity | High precision across the chamber | Guarantees consistent thermal history for all samples to avoid data discrepancies. |

| Target Temperature | Stable 800°C | Standard benchmark for monitoring slow γ' phase coarsening and carbide evolution. |

| Control System | High reliability & multi-stage capability | Prevents system failure during years of testing; essential for initial solution treatments. |

Maximize Your Material Research Precision with KINTEK

Don't let equipment failure compromise 10,000 hours of critical research. KINTEK provides high-performance, customizable thermal solutions designed for the rigorous demands of superalloy stability testing.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need the extreme endurance of a long-term aging furnace or the high-temperature precision of a 1160°C solution treatment system, our lab furnaces are built to your unique specifications.

Ready to secure your data integrity? Contact our technical experts today to discuss your custom furnace requirements and see how KINTEK can enhance your lab's efficiency.

Visual Guide

References

- Yidong Wu, Xidong Hui. Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C. DOI: 10.3390/met14121461

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the options for rapid cooling in custom vacuum furnaces? Achieve Precise Metallurgical Control

- How does a vacuum heat treatment furnace compare to traditional heat treatment methods? Discover Precision and Quality Benefits

- How does a modern pressure sintering furnace operate? Unlock High-Density Materials with Precision

- What role do vacuum pumping systems play in vacuum furnaces? Ensure Purity and Control in Thermal Processes

- What is the significance of using a vacuum diffusion annealing furnace for thermodynamic equilibrium studies in alloys?

- Why is precise temperature and time control in a vacuum brazing furnace necessary for joint performance? Get Expert Tips

- How are vacuum annealing furnaces utilized in electronic material research and development? Unlock Purity and Precision for Advanced Electronics

- What are the overall advantages of vacuum furnaces? Achieve Purity, Precision, and Repeatability