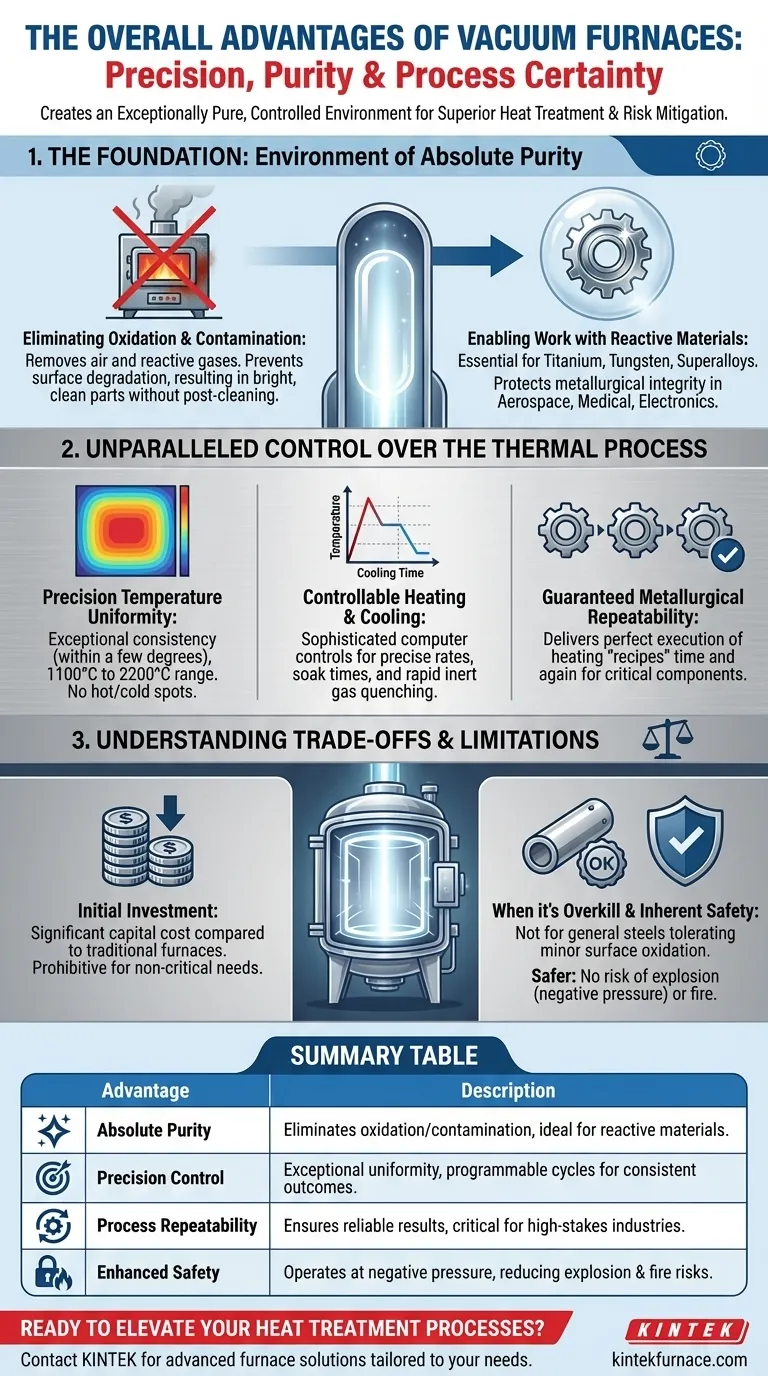

The fundamental advantage of a vacuum furnace is its ability to create an exceptionally pure and precisely controlled environment for heat treatment. By removing the air and its reactive gases, these furnaces prevent contamination and oxidation, enabling superior material properties, enhanced surface finishes, and a level of process repeatability that conventional furnaces cannot match.

While often discussed in terms of temperature control and cleanliness, the true value of a vacuum furnace is risk mitigation. It eliminates atmospheric variables, guaranteeing that a material's final properties are the result of the thermal process alone, not an uncontrolled reaction with its environment.

The Foundation: An Environment of Absolute Purity

A vacuum furnace's core benefit stems from what it removes: the atmosphere. This fundamentally changes the nature of high-temperature processing.

Eliminating Oxidation and Contamination

In a conventional furnace, the oxygen and nitrogen in the air react with the hot surface of a metal. This leads to oxidation (scaling) and decarburization, which degrade the surface finish and mechanical properties of the part.

A vacuum furnace pumps nearly all the air out of its chamber, creating an inert environment. This prevents high-temperature reactions, resulting in bright, clean parts that often require no subsequent cleaning.

Enabling Work with Reactive Materials

Materials like titanium, tungsten, molybdenum, and various superalloys are highly reactive at elevated temperatures. Exposing them to oxygen, even in trace amounts, can be catastrophic to their metallurgical integrity.

The air-free environment of a vacuum furnace is the only way to properly heat-treat these advanced and reactive materials, making it an indispensable tool in the aerospace, medical, and electronics industries.

Unparalleled Control Over the Thermal Process

Removing the atmosphere also gives the operator unprecedented control over the heating and cooling of the workpiece.

Precision Temperature Uniformity

Without air currents to create hot and cold spots, vacuum furnaces achieve exceptional temperature uniformity, often within a few degrees across a wide range of 1100°C to 1500°C. High-vacuum models can reach temperatures as high as 2200°C.

This uniformity ensures that every part in the load, and every section of each part, receives the exact same thermal treatment.

Controllable Heating and Cooling

Modern vacuum furnaces use sophisticated computer controls to manage the entire thermal cycle. This allows for precisely programmed heating rates, soak times, and cooling rates.

Many systems incorporate rapid gas quenching, using inert gas like nitrogen or argon to cool parts quickly and controllably, which is critical for achieving specific hardness and microstructure targets.

Guaranteed Metallurgical Repeatability

The combination of a pure environment and computer control delivers unmatched process repeatability. Once a successful heating "recipe" is developed, a vacuum furnace can execute it perfectly time and again.

This consistency is vital for critical components where slight deviations in material properties could lead to failure.

Understanding the Trade-offs and Limitations

While powerful, a vacuum furnace is not always the right tool for every job. Objectively weighing its costs and benefits is key.

The Initial Investment

The primary drawback of vacuum furnace technology is its cost. These are complex systems that represent a significant capital investment compared to traditional atmosphere furnaces.

This cost can be prohibitive for shops that do not have a clear and consistent need for high-purity heat treatment.

When a Vacuum Furnace is Overkill

Many general-purpose heat treatments on common carbon steels do not require the absolute purity of a vacuum. If the application can tolerate minor surface oxidation that is later removed by shot blasting or machining, a conventional furnace is often more cost-effective.

The necessity of a vacuum furnace must be carefully evaluated based on the specific material and the performance requirements of the final part.

Inherent Process Safety

Compared to pressure vessels or fuel-fired furnaces, vacuum furnaces offer a higher degree of safety. Operating at negative pressure means there is no risk of an explosion due to over-pressurization.

Furthermore, the low-oxygen environment virtually eliminates the risk of fire from flammable materials or workpiece oxidation.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your materials and end-use components.

- If your primary focus is processing high-performance or reactive alloys: A vacuum furnace is non-negotiable to prevent catastrophic oxidation and ensure material integrity.

- If your primary focus is achieving maximum part cleanliness and a bright surface finish: The vacuum environment eliminates the source of most high-temperature discoloration and contamination.

- If your primary focus is ensuring absolute batch-to-batch consistency for critical components: The computer-controlled, repeatable nature of a vacuum furnace is its greatest strength.

- If your primary focus is general heat treating of standard steels on a budget: A traditional atmosphere furnace may be a more cost-effective solution if the application can tolerate minor surface changes.

Ultimately, choosing a vacuum furnace is an investment in process certainty and final-part quality.

Summary Table:

| Advantage | Description |

|---|---|

| Absolute Purity | Eliminates oxidation and contamination by removing air, ideal for reactive materials like titanium and superalloys. |

| Precision Control | Offers exceptional temperature uniformity and programmable heating/cooling cycles for consistent outcomes. |

| Process Repeatability | Ensures reliable, repeatable results critical for aerospace, medical, and electronics industries. |

| Enhanced Safety | Operates at negative pressure, reducing explosion risks and fire hazards. |

Ready to elevate your heat treatment processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental requirements. Don't let contamination or inconsistent results hold you back—contact us today to discuss how our vacuum furnaces can deliver superior material properties and process certainty for your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment