At its core, an induction furnace is a system comprised of a power supply, an induction coil, and a crucible or vessel to hold the material. These primary components work together to convert electrical energy into a powerful magnetic field, which in turn heats a conductive material without any direct flame or contact-based heating element.

The essential insight is that an induction furnace is not just a container that gets hot. It is an electromagnetic system where the material itself becomes the source of heat, driven by a high-frequency power supply and a water-cooled copper coil.

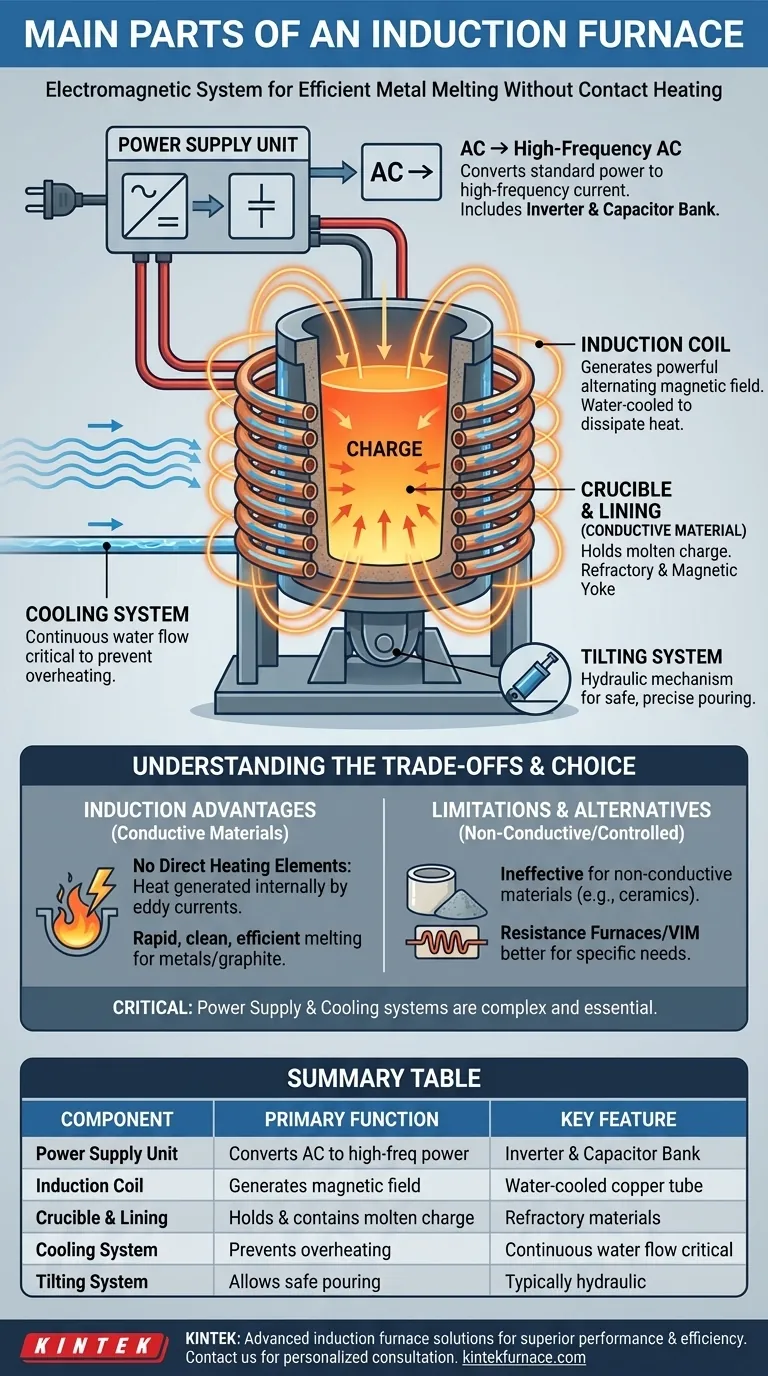

The Core Components and Their Function

An induction furnace’s design is a direct reflection of its unique heating principle. Each part serves a critical role in generating, controlling, and containing the intense energy required for melting metals.

The Power Supply Unit

This is the brain and muscle of the operation. It takes standard utility power (at 50 or 60 Hz) and converts it into the high-current, high-frequency AC power needed by the induction coil. This unit typically includes an inverter for frequency conversion and a capacitor bank to optimize the electrical efficiency of the furnace circuit.

The Induction Coil

The coil is the heart of the furnace. It is a hollow copper tube, wound into a helical shape, through which the high-frequency electrical current from the power supply flows. This current generates a strong, rapidly alternating magnetic field in the center of the coil. The coil is almost always water-cooled to dissipate the immense heat generated by the high current passing through it.

The Furnace Body and Crucible

This assembly contains the material to be heated, known as the charge.

- The Crucible: A refractory container made of materials like clay-graphite or silicon carbide, it sits inside the induction coil and holds the molten metal. It must be able to withstand extreme temperatures and thermal shock.

- The Refractory Lining: In larger, coreless furnaces, a dense refractory cement is packed between the coil and the charge. This lining protects the vital induction coil from the molten metal in case the crucible fails.

- The Magnetic Yoke: Laminated steel packets are often placed around the outside of the coil. These yokes confine the magnetic field, preventing it from inducing heat in the furnace's external steel structure and improving overall energy efficiency.

The Cooling System

This is a non-negotiable safety and operational component. A continuous flow of water, typically through the hollow induction coil and power supply components, is required to prevent them from overheating and failing. Insufficient cooling is one of the most common causes of catastrophic furnace damage.

The Tilting and Control System

For furnaces designed for melting and pouring, a hydraulic tilting system is used. This allows operators to safely and precisely tilt the entire furnace body to pour the molten metal into a ladle or mold. A control box gives the operator command over the tilting mechanism.

Understanding the Trade-offs

The components of an induction furnace highlight its unique advantages and limitations compared to other furnace types.

No Direct Heating Elements

Unlike tube or retort furnaces that rely on resistance heating elements (like silicon carbide or molybdenum rods) to radiate heat, an induction furnace has no hot element. The magnetic field passes through the crucible wall and induces an electrical current directly within the conductive charge material itself. This resistance to current flow (known as an eddy current) is what generates the heat.

Reliance on Conductive Materials

This heating principle means that induction furnaces are primarily effective for materials that conduct electricity, such as metals and graphite. They are inefficient or completely ineffective for heating electrically insulating materials like most ceramics, which would require a resistance-heated furnace.

The Criticality of Power and Cooling

The high power densities and large electrical currents mean that the power supply and cooling systems are far more complex and critical than in a simple resistance furnace. A failure in the cooling water supply can destroy an induction coil in seconds.

Making the Right Choice for Your Application

Understanding these components helps you select the right technology for your specific goal.

- If your primary focus is rapid, clean, and efficient melting of conductive metals: An induction furnace is the ideal choice due to its direct heating, excellent stirring action, and high energy efficiency.

- If your primary focus is processing materials in a controlled vacuum or atmosphere: A specialized vacuum induction melting (VIM) furnace combines these principles, but for simpler heat treatment, a resistance-heated vacuum or retort furnace may be more suitable.

- If your primary focus is high-temperature testing or synthesis of non-conductive materials: A tube furnace with resistance heating elements is the correct tool, as the induction principle would not work.

Ultimately, choosing the right furnace begins with understanding how its core components align with the fundamental physics of your material and process.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Power Supply Unit | Converts standard AC to high-frequency power | Includes inverter and capacitor bank |

| Induction Coil | Generates the alternating magnetic field | Water-cooled hollow copper tube |

| Crucible & Lining | Holds and contains the molten metal charge | Made of refractory materials |

| Cooling System | Prevents overheating of coil and electronics | Continuous water flow is critical |

| Tilting System | Allows for safe pouring of molten metal | Typically hydraulic |

Ready to leverage the power of induction melting for your metal processing needs?

KINTEK's advanced induction furnace solutions are engineered for superior performance, energy efficiency, and process control. Our expertise in R&D and in-house manufacturing allows us to provide robust systems tailored to your specific operational requirements, whether for rapid melting, precise temperature control, or specialized applications like Vacuum Induction Melting (VIM).

Contact our experts today to discuss how our technology can enhance your productivity and product quality. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of using a four-arc furnace for LaRu3Si2 single crystals? Achieve Thermal Symmetry and Growth

- What precautions should be taken when melting PGM powders in an induction furnace? Ensure Safety and Maximize Yield

- Why are multiple vacuum-argon cycles necessary for an induction heating furnace? Ensure Pure Combustion Synthesis

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- Why is it necessary to pre-melt titanium before CoCrFeNiZr0.3 alloys? Essential Purification for Purity

- What are the key benefits of choosing a Vacuum Induction Melting Furnace? Achieve Ultimate Control for High-Purity Metals

- What does the driver circuit in an IGBT-based induction heater consist of and what is its function? Master High-Frequency Power Control

- What are the main steps in vacuum casting? Master High-Quality Prototyping and Low-Volume Production