In short, an induction furnace's main advantages are its exceptional energy efficiency, precise temperature control, and its ability to produce clean, high-quality molten metal. These benefits stem from its unique method of using electromagnetic induction to heat the metal directly, rather than relying on external fuel combustion or heating elements.

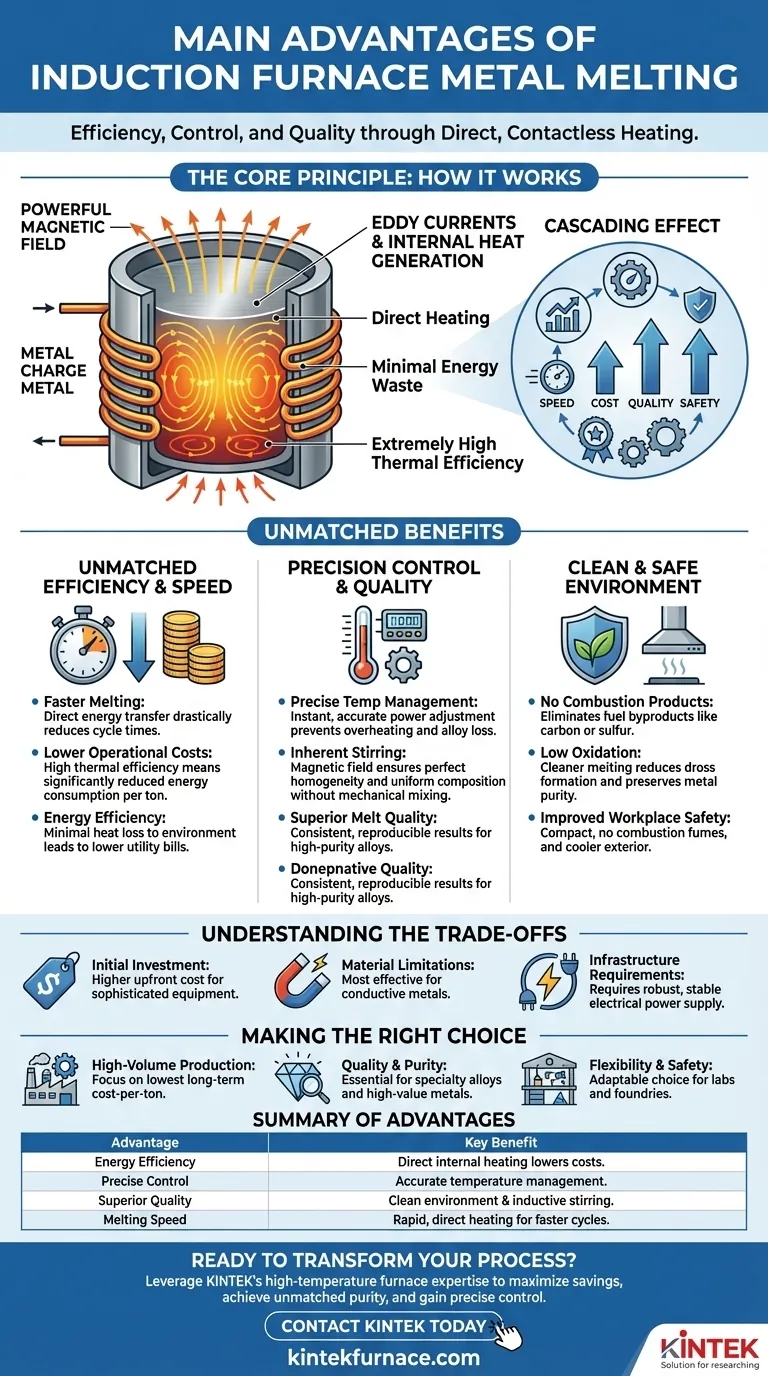

The core advantage of induction technology is not just a single feature, but how its fundamental principle—direct, contactless heating—creates a cascading effect of benefits in speed, cost, quality, and safety that traditional furnaces cannot match.

The Core Principle: How Induction Delivers Superior Efficiency

An induction furnace operates on a different principle than fuel-fired or standard resistance furnaces. This core difference is the source of its primary advantages.

Direct Heating Minimizes Energy Waste

An induction coil generates a powerful, alternating magnetic field. When a conductive metal is placed inside this field, it induces electric currents (known as eddy currents) within the metal itself.

The resistance of the metal to the flow of these currents generates intense, precise heat. Because the heat is generated inside the workpiece, thermal efficiency is extremely high, with minimal energy lost to the surrounding environment.

Unmatched Melting Speed

This direct heating method transfers energy to the metal with incredible speed and efficiency. This results in significantly faster melting times compared to conventional methods, which must first heat the furnace chamber and then transfer that heat to the charge via radiation and convection.

Lower Operational Costs

The combination of high thermal efficiency and rapid melting leads to a noticeable reduction in energy consumption per ton of metal melted. This energy efficiency translates directly into lower utility bills and reduced overall operational costs.

Achieving Unprecedented Control and Quality

Efficiency is only part of the equation. Induction technology provides a level of control that directly impacts the quality of the final product.

Precision Temperature Management

The power supplied to the induction coil can be adjusted instantly and with great precision. This allows for exceptionally accurate temperature control of the melt, preventing overheating and the loss of valuable alloying elements.

Inherent Stirring for Homogenous Melts

The magnetic field that heats the metal also creates a stirring action within the molten bath. This inductive stirring is a unique benefit, as it naturally mixes the metal to ensure a perfectly homogenous and uniform alloy composition without mechanical equipment.

A Clean, Controlled Melting Environment

Since there is no combustion, no fuel byproducts like carbon or sulfur are introduced into the melt. This process creates a clean melting environment with low oxygen, which minimizes oxidation and dross formation, preserving the purity and integrity of the metal.

Understanding the Trade-offs

While powerful, induction technology is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

Initial Capital Investment

Induction furnace systems typically have a higher upfront cost compared to simpler fuel-fired furnaces. The sophisticated power supplies and copper coils represent a significant initial investment.

Material and Charge Limitations

The process relies on electromagnetic principles, meaning it is most effective for melting conductive metals. While advanced techniques exist, melting non-conductive materials or charges with very poor electrical continuity can be inefficient or impractical.

Infrastructure Requirements

These furnaces require a robust and stable electrical power supply, often three-phase power with high capacity. Facilities may need to upgrade their electrical infrastructure to support the system, adding to the initial setup cost and complexity.

Making the Right Choice for Your Application

Selecting the right melting technology depends entirely on your primary operational goal.

- If your primary focus is cost-effective, high-volume production: The superior energy efficiency and fast cycle times of induction will deliver the lowest cost-per-ton over the long term.

- If your primary focus is quality and material purity: The precise temperature control, clean environment, and inherent stirring of an induction furnace are non-negotiable for producing specialty alloys or high-purity metals.

- If your primary focus is operational flexibility and workplace safety: The compact footprint, rapid startup, and lack of combustion fumes make induction a safer and more adaptable choice for labs, foundries with varied jobs, or indoor facilities.

Ultimately, choosing an induction furnace is an investment in process control, operational efficiency, and final product quality.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Direct internal heating minimizes waste, lowering operational costs. |

| Precise Control | Accurate temperature management prevents overheating and alloy loss. |

| Superior Melt Quality | Clean environment and inductive stirring ensure homogenous, pure metal. |

| Melting Speed | Rapid, direct heating leads to significantly faster cycle times. |

Ready to Transform Your Metal Melting Process?

Choosing the right furnace technology is critical for achieving your production goals in cost, quality, and efficiency. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions tailored to your unique challenges.

Our high-temperature furnace expertise can help you:

- Maximize Energy Savings with highly efficient melting systems.

- Achieve Unmatched Purity for specialty alloys and high-value metals.

- Gain Precise Process Control to ensure consistent, high-quality results.

Whether you are melting conductive metals in a foundry or a lab, our team is ready to design a solution that fits your specific needs.

Contact KINTEL today for a consultation and discover how our induction furnace solutions can elevate your operation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production