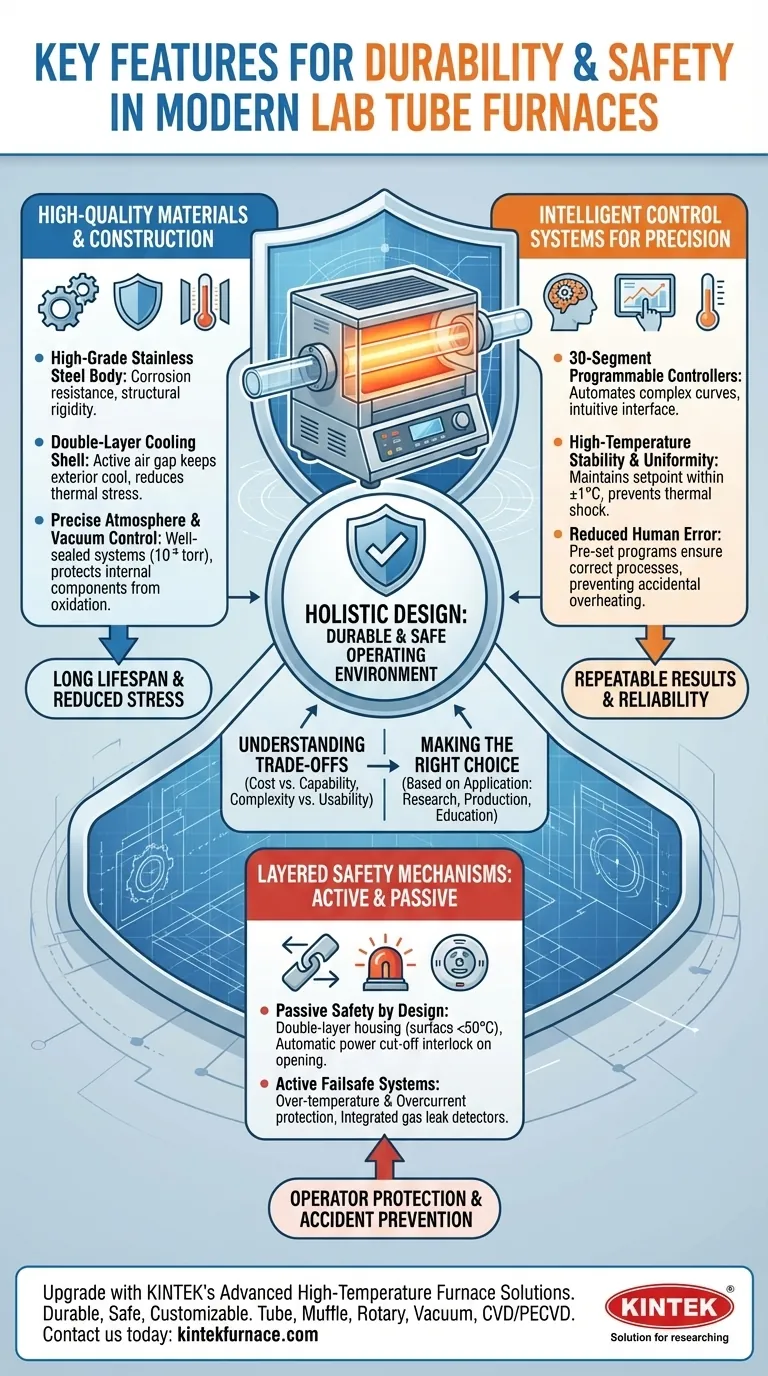

At their core, modern lab tube furnaces ensure durability and safety through a combination of three critical elements: high-quality, heat-resistant materials; intelligent control systems for precision; and multiple, redundant safety mechanisms. These components work together to create a stable operating environment that protects the equipment, the experiment, and most importantly, the user.

The safety and longevity of a tube furnace are not determined by a single feature, but by a holistic design where robust construction, precise digital control, and layered failsafe systems are fully integrated.

The Pillars of Furnace Durability

Durability is a direct result of thoughtful engineering and material science. It ensures the furnace can withstand thousands of hours of high-temperature cycling without degradation in performance or structural integrity.

High-Quality Materials and Construction

The foundation of a durable furnace is its physical build. Manufacturers use high-grade stainless steel for the main body to resist corrosion and provide structural rigidity.

A key design feature is the double-layer cooling shell. This creates an air gap between the inner hot chamber and the outer casing, which is actively cooled. This design not only keeps the exterior cool for safety but also reduces thermal stress on the outer body, significantly extending its lifespan.

High-Temperature Stability and Uniformity

For repeatable results and long-term reliability, the furnace must maintain a stable and uniform temperature. This is achieved through high-quality heating elements and advanced insulation.

The ability to hold a setpoint with high accuracy, often within ±1°C, prevents thermal shocks that can stress and crack the furnace tube or heating elements over time. Multi-zone configurations further enhance this by allowing for programmed temperature gradients, ensuring uniform heat across the entire sample length.

Precise Atmosphere and Vacuum Control

Many processes require a controlled atmosphere or vacuum. Furnaces achieve this with well-sealed systems, featuring custom end caps and high-quality fittings.

The ability to hold a vacuum down to 10⁻⁵ torr or manage a precise gas mixture protects the internal components from oxidation at high temperatures. This control is not just for the experiment; it's a critical feature for maintaining the furnace's internal health.

Layered Safety Mechanisms: Active and Passive

Modern furnace safety is not an afterthought; it is built into the core design. These systems are best understood as either passive (always on by design) or active (triggering in response to an abnormality).

Passive Safety by Design

Passive safety features protect the operator by their very existence. The most important is the double-layer housing, which keeps the surface temperature low (often below 50°C) even when the interior is at 800°C or higher.

Another critical feature is an automatic power cut-off interlock. This system instantly kills power to the heating elements the moment the furnace door or chamber is opened, preventing exposure to extreme heat and electrical hazards.

Active Failsafe Systems

Active systems constantly monitor the furnace's operation and intervene automatically if a problem is detected. These are non-negotiable for safe operation.

Key systems include over-temperature protection, which shuts the furnace down if it exceeds a maximum setpoint, and overcurrent protection, which guards against electrical faults. For processes using combustible or hazardous gases, integrated gas leak detectors provide an essential layer of environmental safety.

The Role of Intelligent Control in Safety

The control system is the brain of the furnace and a central part of its safety architecture. Modern furnaces use 30-segment programmable controllers with intuitive touchscreen interfaces.

By automating complex heating and cooling curves, these systems drastically reduce the risk of human error. Pre-set programs ensure that processes are run correctly every time, preventing accidental overheating or rapid temperature changes that could compromise the furnace or the experiment.

Understanding the Trade-offs

While advanced features enhance capability, they also introduce complexity and cost. A trusted advisor must help you weigh these factors objectively.

Cost vs. Capability

A multi-zone furnace with advanced gas mixing and high-vacuum capabilities is significantly more expensive than a single-zone, air-only model. Be realistic about your needs. Paying for a maximum temperature of 1800°C is unnecessary if your work is consistently below 1100°C.

Complexity vs. Usability

A highly programmable furnace with dozens of options offers immense flexibility. However, it also has a steeper learning curve and can be configured incorrectly. For a teaching lab or a standardized quality control process, a simpler, more robust controller may be both safer and more efficient.

Process Gas and Vacuum Requirements

The need for a specific atmosphere dictates much of the furnace's design and cost. A furnace designed for inert gas is different from one built to handle corrosive gases or high vacuum. Attempting to use a basic furnace for an advanced application can lead to equipment failure and safety hazards.

Making the Right Choice for Your Application

Select a furnace based on its suitability for your primary goal, not just its maximum specifications.

- If your primary focus is advanced materials research: Prioritize a furnace with multi-zone control for temperature gradients, precise atmosphere and vacuum systems, and data logging capabilities.

- If your primary focus is high-throughput production or QA: Emphasize reliability, automated programmable controls for repeatability, and robust safety interlocks for operator protection.

- If your primary focus is general educational use: Choose a furnace with outstanding passive safety features like a cool-touch exterior and door interlocks, coupled with an intuitive, easy-to-learn control interface.

Ultimately, view the furnace not as a collection of features, but as a complete system designed to achieve a specific task safely and reliably.

Summary Table:

| Feature Category | Key Elements | Benefits |

|---|---|---|

| Durability | High-grade stainless steel, double-layer cooling shell, high-temperature stability (±1°C), precise atmosphere/vacuum control | Long lifespan, corrosion resistance, reduced thermal stress, repeatable results |

| Safety | Passive (double-layer housing, automatic power cut-off) and active (over-temperature, overcurrent, gas leak detection) systems, intelligent controls | Operator protection, prevents accidents, minimizes human error |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with durable and safe options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and safety. Contact us today to discuss how we can support your research, production, or educational goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability