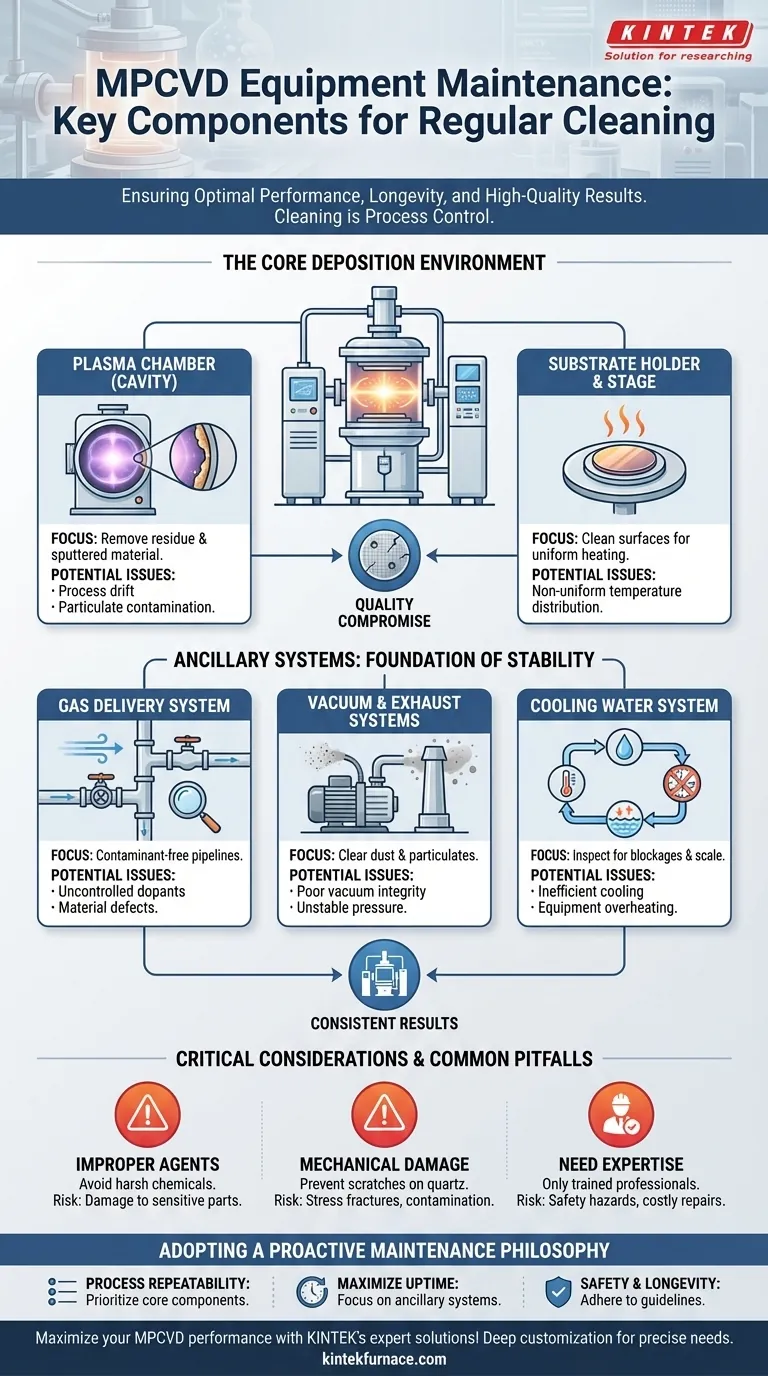

To ensure optimal performance and longevity, the key components requiring regular cleaning in MPCVD equipment are the internal plasma chamber (cavity), substrate holder, gas delivery pipelines, and the vacuum and exhaust systems. Proper maintenance also involves inspecting the cooling water system for blockages and ensuring all system surfaces are free of debris. This routine is not merely about tidiness; it is a critical factor in achieving consistent, high-quality deposition results.

MPCVD cleaning is a form of process control. Moving beyond simple component lists, the goal is to systematically eliminate sources of contamination that degrade vacuum integrity, disrupt plasma stability, and ultimately compromise the quality of the material being grown.

The Core Deposition Environment: Protecting the Process

The components inside and directly connected to the plasma chamber have the most immediate impact on your deposition results. Contamination here directly translates to defects in your final product.

The Plasma Chamber (Cavity)

The inner walls of the chamber accumulate residue from precursor gases and sputtered material from the holder or substrate. This buildup can flake off during a run, creating particulates that contaminate the growth process. More subtly, it can alter the microwave-to-plasma coupling, leading to process drift over time.

Substrate Holder and Stage

The stage that holds your substrate is subject to intense heat and plasma interaction. Any foreign material or buildup on its surface can lead to non-uniform temperature distribution across the substrate. This directly impacts the uniformity and quality of the deposited film.

Ancillary Systems: The Foundation of Stability

The support systems are just as critical as the chamber itself. Their cleanliness and proper function are what guarantee a stable and repeatable process environment.

Gas Delivery System

The pipelines that deliver precursor gases must be impeccably clean. Think of them as the arteries of your system. Any internal contamination can be carried into the chamber, acting as an uncontrolled dopant or a source of defects in your material.

Vacuum and Exhaust Systems

The vacuum system, including pumps and gauges, must maintain a specific base pressure. The exhaust system removes byproducts. Dust and particulate buildup in exhaust lines and filters can reduce pumping efficiency, leading to poor vacuum integrity and unstable chamber pressure during deposition.

Cooling Water System

The cooling system regulates the temperature of critical components like the microwave generator and the chamber walls. Scale or biological growth within the cooling lines can cause blockages, leading to inefficient cooling. This can cause equipment to overheat and shut down, or create temperature instabilities that affect the process.

Critical Considerations and Common Pitfalls

Cleaning MPCVD equipment is a high-stakes task where the wrong approach can be more damaging than no cleaning at all.

The Danger of Improper Cleaning Agents

Never use harsh, abrasive, or strong chemical cleaners unless explicitly specified by the equipment manufacturer. These can damage sensitive components like quartz windows, O-rings, and specialized interior coatings, leading to costly repairs and vacuum leaks. Isopropyl alcohol (IPA) and deionized water are common starting points.

Risk of Mechanical Damage

Care must be taken to avoid scratching interior surfaces, especially quartz components. Scratches can become initiation points for stress fractures or create areas where contamination accumulates, making future cleaning more difficult and less effective.

The Need for Professional Expertise

Due to the complexity, high voltages, and use of specialized gases, maintenance should only be performed by trained professionals. An untrained operator attempting to clean internal components can easily cause damage or create a serious safety hazard. Always follow the manufacturer's specific maintenance protocols.

Adopting a Proactive Maintenance Philosophy

Your approach to cleaning should be driven by your operational goals. A systematic maintenance schedule is essential for preventing problems before they impact your research or production.

- If your primary focus is process repeatability: Your highest priority is cleaning the plasma chamber, substrate holder, and gas delivery lines to eliminate sources of chemical and particulate contamination.

- If your primary focus is maximizing uptime: Pay close attention to cleaning and inspecting the cooling water, vacuum, and exhaust systems to prevent equipment faults and shutdowns.

- If your primary focus is safety and longevity: Adhere strictly to manufacturer guidelines and ensure only trained personnel perform maintenance, using approved materials to avoid damaging the equipment.

Ultimately, viewing regular cleaning as an integral part of your process—not just a chore—is the key to achieving stable, reliable results from your MPCVD system.

Summary Table:

| Component | Key Cleaning Focus | Potential Issues if Neglected |

|---|---|---|

| Plasma Chamber (Cavity) | Remove residue and sputtered material | Process drift, particulate contamination |

| Substrate Holder | Clean surfaces for uniform heating | Non-uniform temperature distribution |

| Gas Delivery System | Ensure pipelines are free of contaminants | Uncontrolled dopants, material defects |

| Vacuum and Exhaust Systems | Clear dust and particulates | Poor vacuum integrity, unstable pressure |

| Cooling Water System | Inspect for blockages and scale | Inefficient cooling, equipment overheating |

Maximize your MPCVD equipment's performance with KINTEK's expert solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing process repeatability, uptime, and safety. Don't let maintenance challenges hold you back—contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab