In essence, programmable stages give you precise control over the entire heating and cooling process of a dental restoration. They allow a technician to customize every phase of the sintering cycle by setting specific temperature ramp rates, defining hold times at critical temperatures, and scheduling delayed starts. This absolute control is the key to achieving the desired material properties in the final restoration.

The ability to program stages is not just a convenience; it is the mechanism for unlocking the full aesthetic and structural potential of modern dental materials. By tailoring the heat treatment, technicians directly influence the final restoration's strength, translucency, and color accuracy.

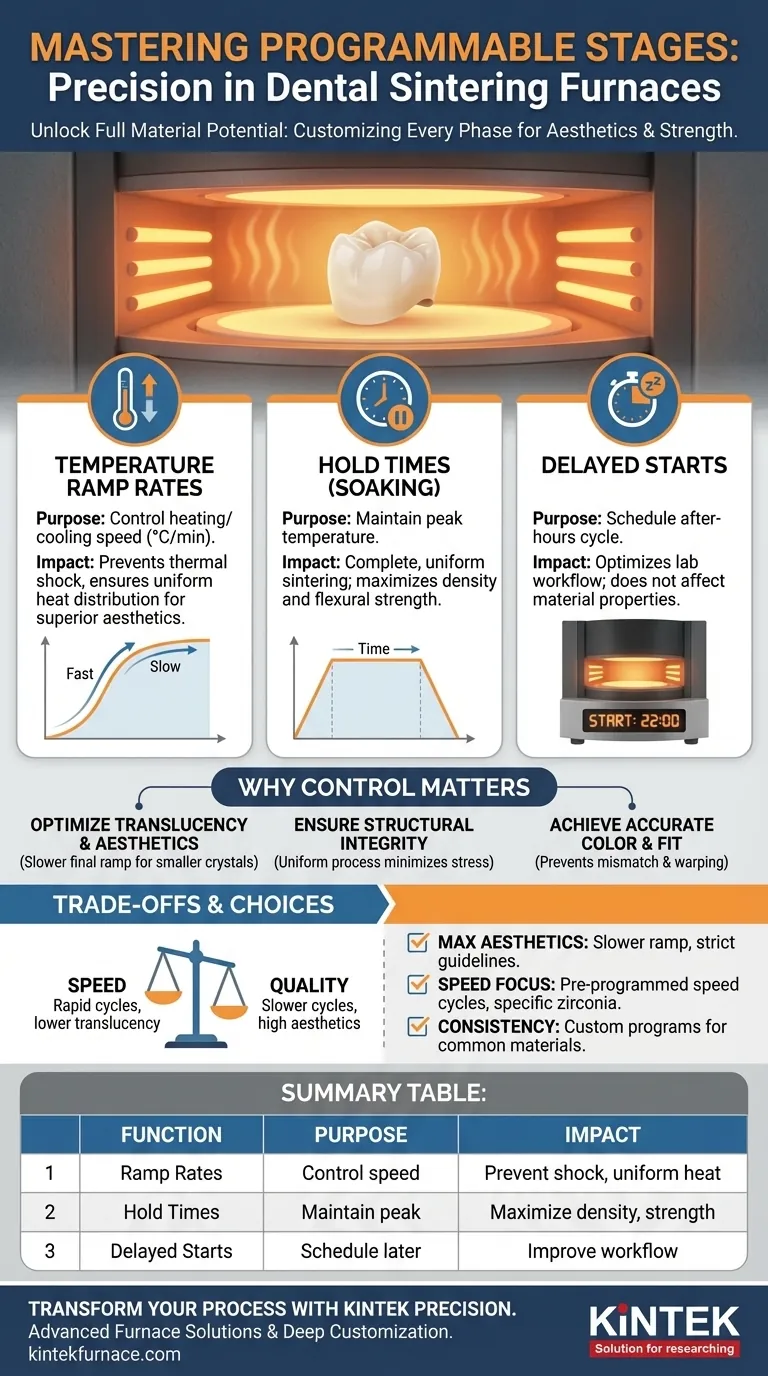

The Core Functions of a Programmable Cycle

A programmable furnace allows you to dictate the exact journey a restoration takes from its "green" state to its final, hardened form. Each stage serves a specific purpose.

Controlling Temperature Ramp Rates

The ramp rate is the speed at which the furnace's temperature increases or decreases, measured in degrees per minute.

Programmable stages allow you to use different ramp rates throughout the cycle. For example, you might program a rapid initial heating phase to save time, followed by a much slower ramp rate as the material approaches its critical sintering temperature.

This slow-down is crucial for preventing thermal shock and allowing for uniform heat distribution, which directly impacts the final aesthetics.

Defining Hold Times (Soaking)

A hold time, or "soak," is a period where the furnace maintains a specific peak temperature without change.

This stage ensures the entire restoration, including its thickest parts, reaches a uniform temperature and is held there long enough for full sintering to occur.

Proper hold times are essential for achieving maximum material density and, consequently, the highest possible flexural strength.

Programming Delayed Starts

This function allows the user to load the furnace but delay the start of the cycle for a set number of hours.

While it doesn't affect the material properties, a delayed start is a significant workflow advantage. A technician can prepare and load restorations at the end of the day and program the furnace to run overnight, ensuring the finished work is ready for them in the morning.

Why This Control Matters for Restorations

The ability to manipulate these variables is what separates an acceptable result from an exceptional one. It allows the technician to tailor the firing cycle to the specific demands of the material and the desired outcome.

Optimizing Translucency and Aesthetics

The final appearance of a zirconia restoration is highly dependent on the heating cycle.

A slower ramp rate during the final phase of sintering results in smaller crystal grain growth within the zirconia. This structure allows more light to pass through, significantly increasing the material's translucency for a more natural, vital look.

Ensuring Structural Integrity

Rushing the sintering process can introduce internal stresses and prevent the material from reaching its full density.

By programming appropriate ramp rates and hold times, you ensure a controlled, uniform process that minimizes stress and maximizes the restoration's strength, reducing the risk of fractures in the future.

Achieving Accurate Color and Fit

An incorrect sintering cycle can alter the final shade of a restoration, causing a mismatch with the patient's existing teeth.

Furthermore, improper heating can lead to uneven shrinkage or warpage, compromising the marginal fit of the crown or bridge. Precise, programmable control helps guarantee predictable results every time.

Understanding the Trade-offs

While programmability offers immense control, it also requires a clear understanding of the compromises involved.

Speed vs. Quality

The most common trade-off is time versus aesthetics. Rapid sintering cycles can dramatically shorten production time but often do so at the cost of translucency.

While fast cycles are suitable for some cases, high-esthetic anterior restorations almost always benefit from a slower, more controlled firing schedule.

Material-Specific Requirements

There is no universal sintering program. Each type of zirconia—from high-strength opaque to high-translucency aesthetic—has a unique, manufacturer-recommended protocol.

Using a program designed for one material on another can lead to a complete failure of the restoration. Programmability requires the user to be diligent about matching the cycle to the material.

Making the Right Choice for Your Goal

Use the furnace's programmability to align the sintering process with the specific goal of each case.

- If your primary focus is maximum aesthetics and translucency: Prioritize slower ramp rates during the final sintering phase and adhere strictly to the zirconia manufacturer's guidelines for multi-stage cycles.

- If your primary focus is production speed for standard cases: Utilize pre-programmed "speed" cycles, but only with zirconia blocks specifically designed and validated for rapid sintering.

- If your primary focus is consistency and reliability: Create and save custom programs based on the manufacturer's recommendations for the materials you use most often, minimizing the chance of daily programming errors.

Mastering the programmable stages of your furnace transforms it from a simple oven into a precision instrument for crafting superior dental restorations.

Summary Table:

| Function | Purpose | Impact on Restoration |

|---|---|---|

| Temperature Ramp Rates | Controls heating/cooling speed to prevent thermal shock. | Ensures uniform heat distribution for better aesthetics and strength. |

| Hold Times (Soaking) | Maintains peak temperature for complete, uniform sintering. | Maximizes material density and flexural strength. |

| Delayed Starts | Schedules cycle beginning for after-hours operation. | Improves lab workflow efficiency without affecting material properties. |

Transform Your Sintering Process with KINTEK Precision

Mastering programmable stages is key to producing superior dental restorations, but it requires a furnace built with precision and reliability. KINTEK leverages exceptional R&D and in-house manufacturing to provide dental laboratories with advanced high-temperature furnace solutions.

Our product line, including Tube Furnaces and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your lab's unique workflow and material requirements.

Ready to achieve unparalleled consistency, aesthetics, and strength in your zirconia restorations?

Contact KINTEK today to discuss how our sintering solutions can be tailored to elevate your lab's performance and output.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision