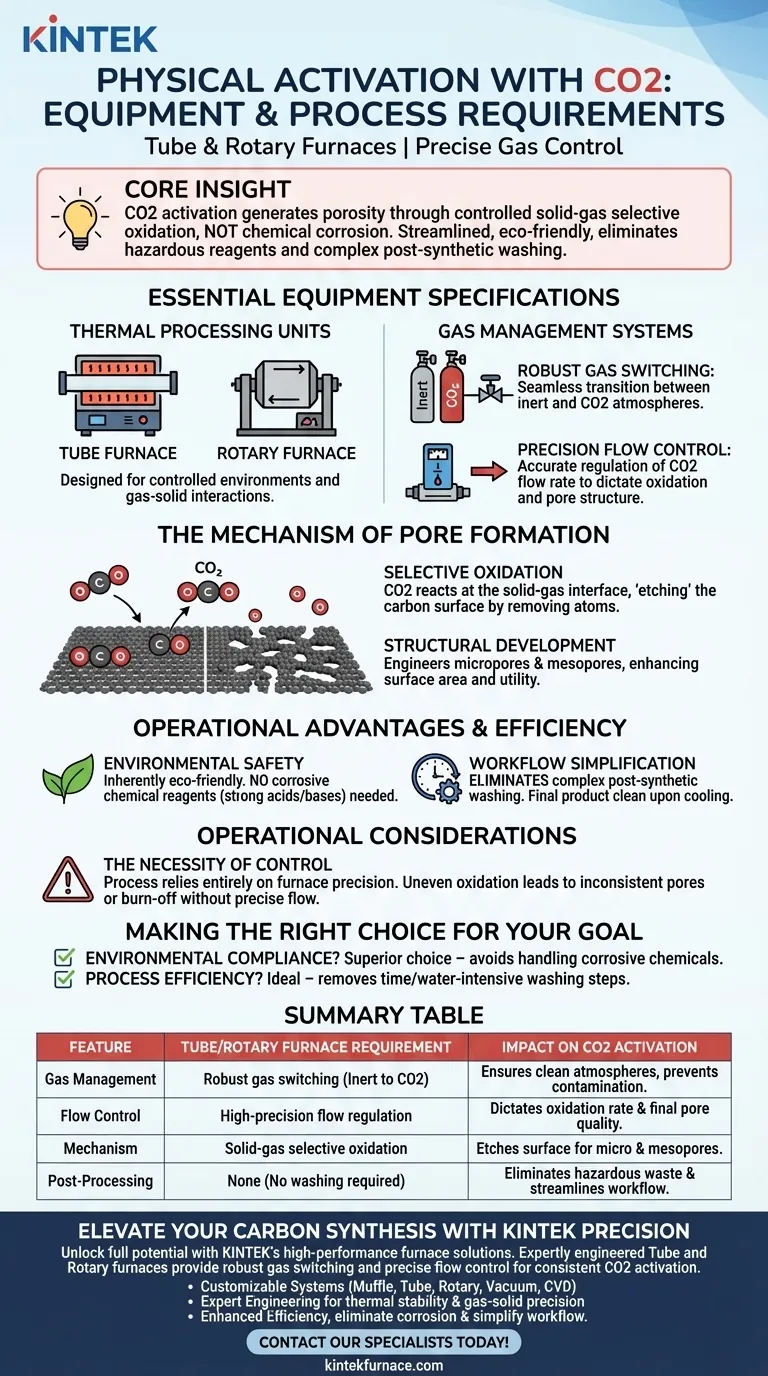

Physical activation with carbon dioxide (CO2) requires specific thermal processing units, primarily tube furnaces or rotary furnaces, that are equipped with advanced gas management systems. To successfully execute this process, these furnaces must feature robust gas switching capabilities and precise flow control to manage the selective oxidation occurring at the solid-gas interface.

Core Insight: CO2 activation distinguishes itself by generating porosity through controlled, solid-gas oxidation rather than chemical corrosion. This method offers a streamlined, environmentally friendly workflow that completely eliminates the need for hazardous reagents and the complex post-synthetic washing steps required by chemical activation.

Essential Equipment Specifications

Thermal Processing Units

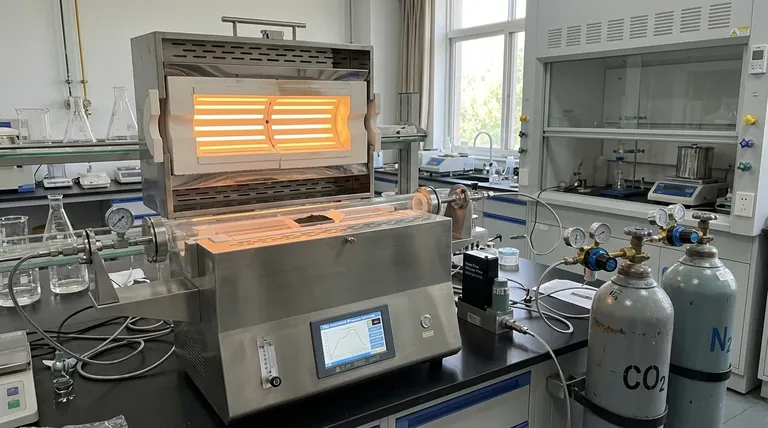

The foundation of physical activation lies in the furnace type. The process specifically demands the use of tube furnaces or rotary furnaces.

These units are designed to maintain the controlled environments necessary for gas-solid interactions.

Gas Management Systems

The primary reference highlights the critical need for robust gas switching.

This feature allows operators to seamlessly transition between different gas atmospheres (e.g., inert gas to CO2) without interrupting the thermal process or contaminating the sample.

Precision Flow Control

Standard gas valves are insufficient for this process. The equipment must possess precise flow control capabilities.

Accurate regulation of the CO2 flow rate is essential to control the rate of oxidation, which directly dictates the quality of the final pore structure.

The Mechanism of Pore Formation

Selective Oxidation

Unlike chemical activation, which relies on mixing solid reagents, CO2 activation functions through selective oxidation at the solid-gas interface.

The CO2 molecule reacts with the carbon surface, removing carbon atoms in a controlled manner to "etch" the material.

Structural Development

This oxidative process is highly effective at engineering specific internal structures.

Correctly executed, CO2 activation generates significant volumes of micropores and mesopores, enhancing the surface area and utility of the final carbon material.

Operational Advantages and Efficiency

Environmental Safety

The process is inherently environmentally friendly.

By utilizing CO2, you avoid the use of corrosive chemical reagents (such as strong acids or bases) typically associated with chemical activation methods.

Workflow Simplification

A major efficiency gain in CO2 activation is the elimination of post-processing steps.

Because no chemical agents are impregnated into the material, the process eliminates the need for complex post-synthetic washing. The final product is cleaner immediately upon cooling.

Operational Considerations

The Necessity of Control

While the process simplifies the workflow by removing washing steps, it shifts the burden of complexity to the equipment control.

Success relies entirely on the precision of the furnace's gas system. Without precise flow control, the oxidation may become uneven, leading to inconsistent pore development or excessive burn-off of the material.

Making the Right Choice for Your Goal

When deciding if CO2 activation is the right method for your carbon synthesis, consider your operational priorities:

- If your primary focus is Environmental Compliance: CO2 activation is the superior choice as it avoids the storage, handling, and disposal of corrosive chemical reagents.

- If your primary focus is Process Efficiency: This method is ideal because it removes the time-consuming and water-intensive washing steps required to purify chemically activated carbons.

Physical activation with CO2 offers a high-precision, clean alternative to chemical methods, provided your thermal equipment can deliver the necessary stability and gas flow accuracy.

Summary Table:

| Feature | Tube/Rotary Furnace Requirement | Impact on CO2 Activation |

|---|---|---|

| Gas Management | Robust gas switching (Inert to CO2) | Ensures clean atmospheres and prevents contamination. |

| Flow Control | High-precision flow regulation | Dictates oxidation rate and final pore structure quality. |

| Mechanism | Solid-gas selective oxidation | Etches carbon surface to create micro and mesopores. |

| Post-Processing | None (No washing required) | Eliminates hazardous waste and streamlines workflow. |

Elevate Your Carbon Synthesis with KINTEK Precision

Unlock the full potential of physical activation with KINTEK’s high-performance furnace solutions. Whether you are developing advanced microporous materials or eco-friendly carbon structures, our expertly engineered Tube and Rotary furnaces provide the robust gas switching and precise flow control essential for consistent CO2 activation results.

Why choose KINTEK?

- Customizable Systems: Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific R&D or manufacturing needs.

- Expert Engineering: Backed by industry-leading R&D to ensure thermal stability and gas-solid interface precision.

- Enhanced Efficiency: Eliminate chemical corrosion and simplify your workflow with our advanced thermal processing units.

Contact our specialists today to find your perfect furnace solution!

Visual Guide

References

- Xing Huang, Dessie Ashagrie Tafere. Waste-derived green N-doped materials: mechanistic insights, synthesis, and comprehensive evaluation. DOI: 10.1039/d5su00555h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the limitations of quartz tubes in rotary furnaces? Key Constraints and Alternatives

- What are the key technical specifications of a Rotary Tube Tilt Furnace? Optimize Your Thermal Processing

- Which advanced technologies are incorporated into rotary kilns to improve their performance? Boost Efficiency & Precision

- How are rotary furnaces used in lead recovery processes? Maximize Efficiency in Industrial Recycling

- In what ways are rotary furnaces environmentally friendly? Boost Energy Efficiency & Waste Recycling

- What industrial applications benefit from indirect-fired rotary kilns? Achieve Purity and Control in High-Temp Processing

- What are the main advantages of a rotary tube sintering furnace? Achieve Superior Uniformity and Efficiency

- Why is maintenance more complex for rotary furnaces? Key Challenges and Solutions