Indirect-fired rotary kilns are the technology of choice for high-temperature thermal processing where material purity is paramount. They excel in applications requiring a controlled atmosphere, making them essential for producing advanced materials, performing pyrolysis, and purifying sensitive chemical compounds where direct contact with combustion gases would cause contamination or unwanted side reactions.

The core decision to use an indirect-fired kiln over a direct-fired one is a strategic trade-off. You are choosing absolute process control and material purity over the higher thermal efficiency and scale typically associated with direct-fired systems.

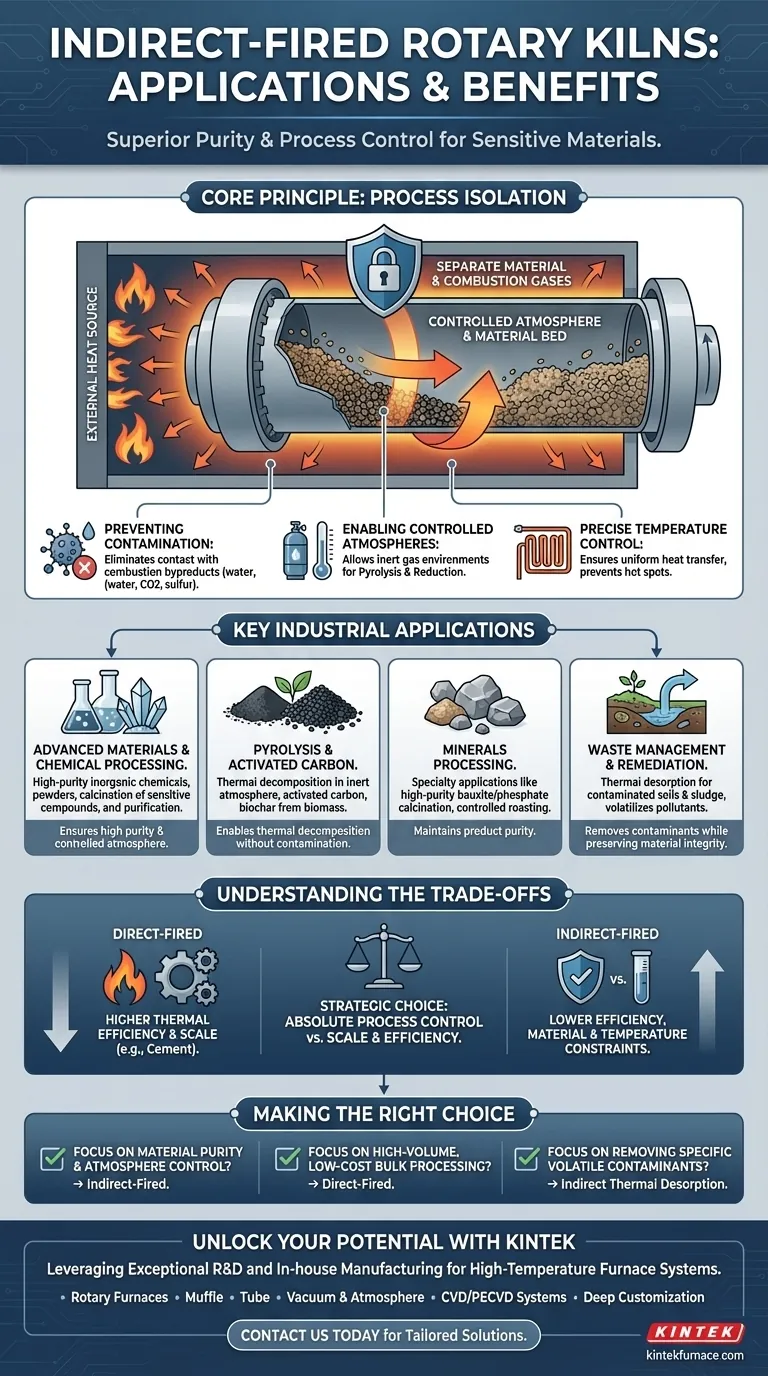

The Core Principle: Process Isolation

The fundamental advantage of an indirect-fired kiln is the complete separation of the material being processed from the heat source and its combustion byproducts. The kiln's rotating shell is heated from the outside, and that heat transfers through the shell wall to the material tumbling inside.

Preventing Material Contamination

In a direct-fired kiln, the flame and hot gases pass directly over the material, which is efficient but introduces byproducts like water vapor, carbon dioxide, and sulfur.

Indirect firing eliminates this. It is critical for high-value products like phosphors, titanates, and specialty zinc oxides, where even trace impurities can ruin the final product's performance.

Enabling Controlled Atmospheres

Because the internal process environment is sealed off from the external heating chamber, a specific atmosphere can be introduced and maintained.

This allows for processes that are otherwise impossible in the presence of oxygen. This includes pyrolysis (thermal decomposition in an inert atmosphere) and reduction reactions that use gases like hydrogen.

Precise and Uniform Temperature Control

Heating the shell externally allows for a more gentle and uniform transfer of heat to the material bed.

This prevents localized hot spots, ensuring every particle experiences a similar thermal history. This precision is vital for creating products with consistent quality and predictable physical properties.

Key Industrial Applications

This principle of process isolation makes indirect kilns uniquely suited for several specific industrial processes and materials.

Advanced Materials & Chemical Processing

Indirect kilns are used to produce high-purity inorganic chemicals and powders. This includes the calcination of sensitive compounds where a specific crystalline structure must be achieved without introducing impurities.

They are also used for purification, driving off volatile elements from a valuable base material at high temperatures.

Pyrolysis and Activated Carbon

Pyrolysis is the thermal decomposition of organic material in the absence of oxygen. Indirect firing is the only practical way to achieve this in a continuous rotary system.

This process is the foundation for manufacturing activated carbon, biochar, and other carbon products from feedstocks like wood, coconut shells, or coal.

Minerals Processing

While direct-fired kilns handle bulk minerals like limestone, indirect kilns are used for specialty mineral applications.

This includes the calcination of bauxite or phosphate ore where product purity is a key specification, or roasting minerals to induce specific chemical changes in a controlled atmosphere.

Waste Management & Remediation

Thermal desorption is a key application in environmental remediation. An indirect-fired kiln can be used to heat contaminated soils or industrial sludge.

The controlled heating volatilizes contaminants like hydrocarbons or mercury, which are then collected from the off-gas for treatment, leaving the clean soil behind. The process removes the contaminant without destroying the soil matrix itself.

Understanding the Trade-offs

While powerful, indirect-fired kilns are not a universal solution. Their primary advantage—process isolation—creates inherent limitations.

Thermal Efficiency and Scale

Transferring heat through a thick, rotating steel or alloy shell is less efficient than heating the material with a direct flame. This results in higher fuel consumption per ton of product.

Furthermore, the mechanical challenges of heating and rotating a very large shell place practical limits on the diameter and length of indirect kilns. They are not suitable for the massive throughput required in industries like cement manufacturing.

Material and Temperature Constraints

The kiln shell is subjected to extreme thermal stress. The material of construction (typically a high-temperature steel alloy) dictates the maximum operating temperature and becomes a significant cost driver.

Operating temperatures are often limited by the shell's metallurgical properties to ensure a safe and long operational life.

Making the Right Choice for Your Process

Selecting the correct kiln technology requires a clear understanding of your primary process goal.

- If your primary focus is material purity and atmosphere control: An indirect-fired kiln is the definitive choice for sensitive chemicals, pyrolysis, or creating high-value materials.

- If your primary focus is high-volume, low-cost bulk processing: A direct-fired kiln is almost always the more economical and scalable solution, provided the material can tolerate combustion gases.

- If your primary focus is removing specific volatile contaminants: Indirect thermal desorption offers precise temperature control to target contaminants without combusting the primary material.

Ultimately, understanding the fundamental need for process isolation is the key to deciding if an indirect-fired rotary kiln is the right tool for your application.

Summary Table:

| Application | Key Benefit |

|---|---|

| Advanced Materials & Chemical Processing | Ensures high purity and controlled atmosphere for sensitive compounds |

| Pyrolysis and Activated Carbon | Enables thermal decomposition in inert environments without contamination |

| Minerals Processing | Maintains product purity in calcination and roasting processes |

| Waste Management & Remediation | Removes contaminants via thermal desorption while preserving material integrity |

Unlock the full potential of your thermal processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for purity, efficiency, and reliability. Contact us today to discuss how our tailored indirect-fired rotary kilns can elevate your operations and deliver superior results for your specific applications!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How does customization benefit the use of rotary kilns? Boost Efficiency and Quality with Tailored Solutions

- What types of physical and chemical transformations occur in a rotary kiln? Master Material Processing for Superior Results

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What data is necessary to design a rotary kiln? Essential Factors for Efficient Thermal Processing

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality