At its core, a rotary tube sintering furnace excels where process uniformity is paramount. Its primary advantages are the ability to deliver exceptionally uniform heating and consistent material mixing. This is achieved through a rotating tube that continuously tumbles the material, leading to higher efficiency, faster processing times, and superior control over the final product quality compared to static furnace designs.

Choosing the right furnace isn't just about reaching a target temperature; it's about controlling the entire thermal process. The fundamental advantage of a rotary tube furnace is its ability to simultaneously heat and mix materials, transforming a static thermal process into a dynamic one. This active agitation is the source of its superior uniformity and efficiency.

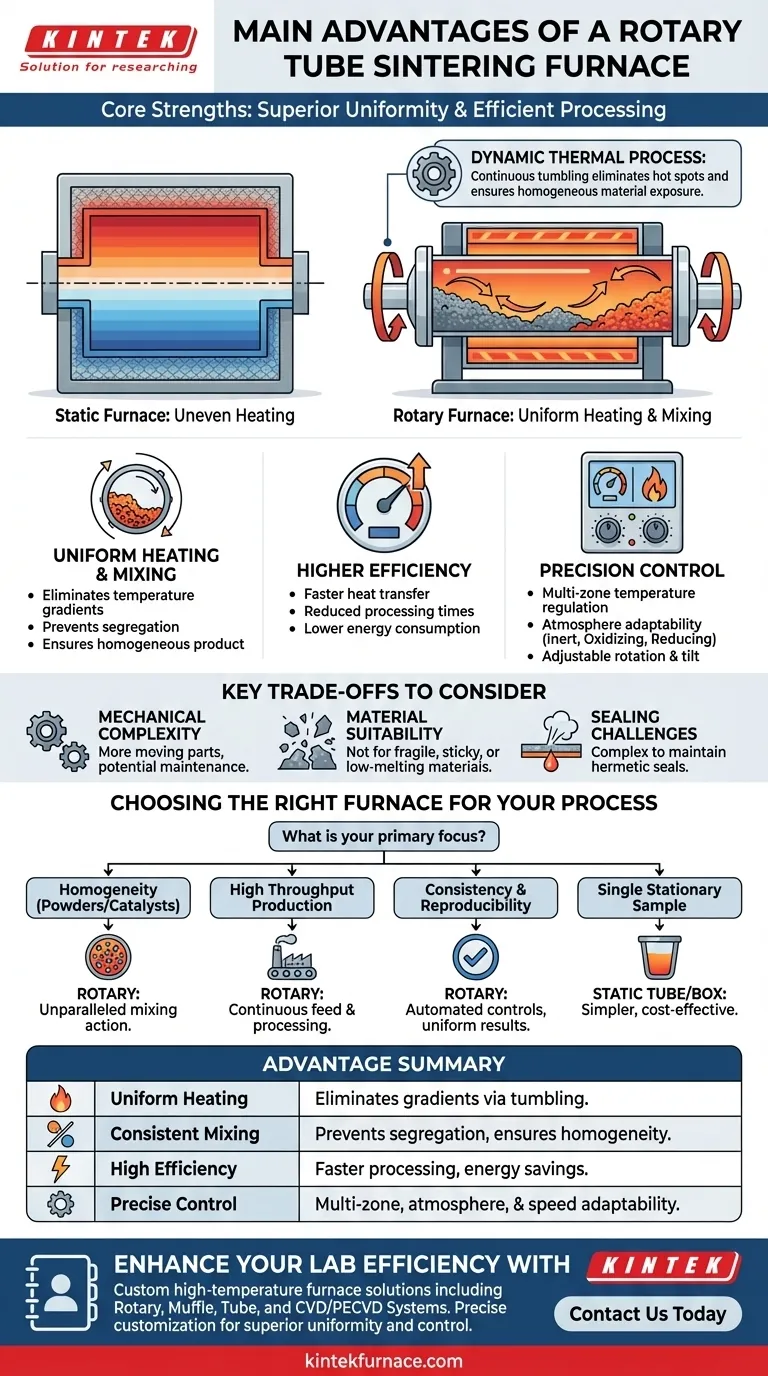

The Foundation: How Dynamic Processing Creates Uniformity

The defining feature of a rotary tube furnace is its rotating quartz or ceramic tube. This simple mechanical action is the source of its most significant benefits.

Eliminating Hot and Cold Spots

In a static furnace, material at the bottom of a crucible can insulate itself, while material on the top and sides gets hotter. A rotary furnace solves this by continuously tumbling the powder or granules.

This action ensures every particle is uniformly exposed to the heat source, eliminating temperature gradients and guaranteeing a homogenous thermal treatment.

Ensuring Consistent Material Mixing

The rotating motion inherently mixes the sample. This is critical for preventing the settling or segregation of different components in a mixture.

For processes like catalyst manufacturing or creating composite powders, this constant agitation ensures the final product is perfectly homogenous.

Superior Heat Transfer Efficiency

By constantly exposing new surfaces to the heat, the tumbling action dramatically improves heat transfer into the bulk of the material.

This leads to faster processing times and greater energy efficiency, as the target temperature is reached more quickly and with less wasted energy.

Precision Control Over the Process Environment

Beyond its mechanical action, a rotary tube furnace provides granular control over every aspect of the thermal environment, enabling highly reproducible results.

Multi-Zone Temperature Regulation

Many models feature multiple, independently controlled heating zones along the length of the tube. This allows you to create a precise temperature profile, which is ideal for complex processes that require distinct heating, soaking, and cooling stages.

Atmosphere Adaptability

These furnaces are designed to operate with controlled atmospheres. You can introduce inert (Nitrogen, Argon), oxidizing (Air), or reducing (Hydrogen mixtures) gases to facilitate or prevent specific chemical reactions during sintering.

Adjustable Mechanical Variables

Key variables like the rotation speed and tilt angle of the tube can be adjusted. This provides direct control over the mixing intensity and the residence time of the material within the heated zone, allowing you to fine-tune the process for different materials.

Understanding the Trade-offs

While powerful, the rotary design introduces complexities that are important to consider.

Mechanical Complexity

The rotation mechanism, including the motor and seals, adds moving parts. Compared to a simpler static tube furnace, this increases the potential need for maintenance over the unit's lifetime.

Material Suitability

The tumbling action is not ideal for all materials. Very fragile materials may be damaged by the mechanical stress, while extremely sticky or low-melting-point materials can cause buildup and agglomeration inside the tube.

Sealing Challenges

Maintaining a perfectly hermetic seal to control the atmosphere can be more complex on a rotating tube than on a static one, especially at the material inlet and outlet points. This is a critical consideration for processes that require an ultra-pure environment.

Making the Right Choice for Your Process

Your decision should be driven by the specific requirements of your material and the desired outcome.

- If your primary focus is creating a perfectly homogenous powder or catalyst: The unparalleled mixing action is the most critical advantage, ensuring uniform chemical and physical properties throughout your material.

- If your primary focus is high-throughput continuous production: The ability to continuously feed and process material makes a rotary furnace far more efficient for production-scale work than batch-based static furnaces.

- If your primary focus is process consistency and reproducibility: The combination of uniform heating and automated controls eliminates key process variables, ensuring every run meets the same quality standard.

- If you are working with a single, stationary solid sample or a liquid precursor: A standard static tube or box furnace is a more straightforward and cost-effective solution.

Ultimately, a rotary tube furnace is the superior choice when the dynamic treatment of the material is as important as the thermal environment itself.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Eliminates hot and cold spots via continuous tumbling for homogenous thermal treatment. |

| Consistent Mixing | Prevents segregation and ensures material homogeneity through constant agitation. |

| High Efficiency | Faster processing and energy savings due to improved heat transfer. |

| Precise Control | Multi-zone temperature, adjustable rotation speed, and atmosphere adaptability for reproducibility. |

Ready to enhance your lab's efficiency with a custom high-temperature furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements for superior uniformity and control. Contact us today to discuss how we can optimize your sintering processes!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits