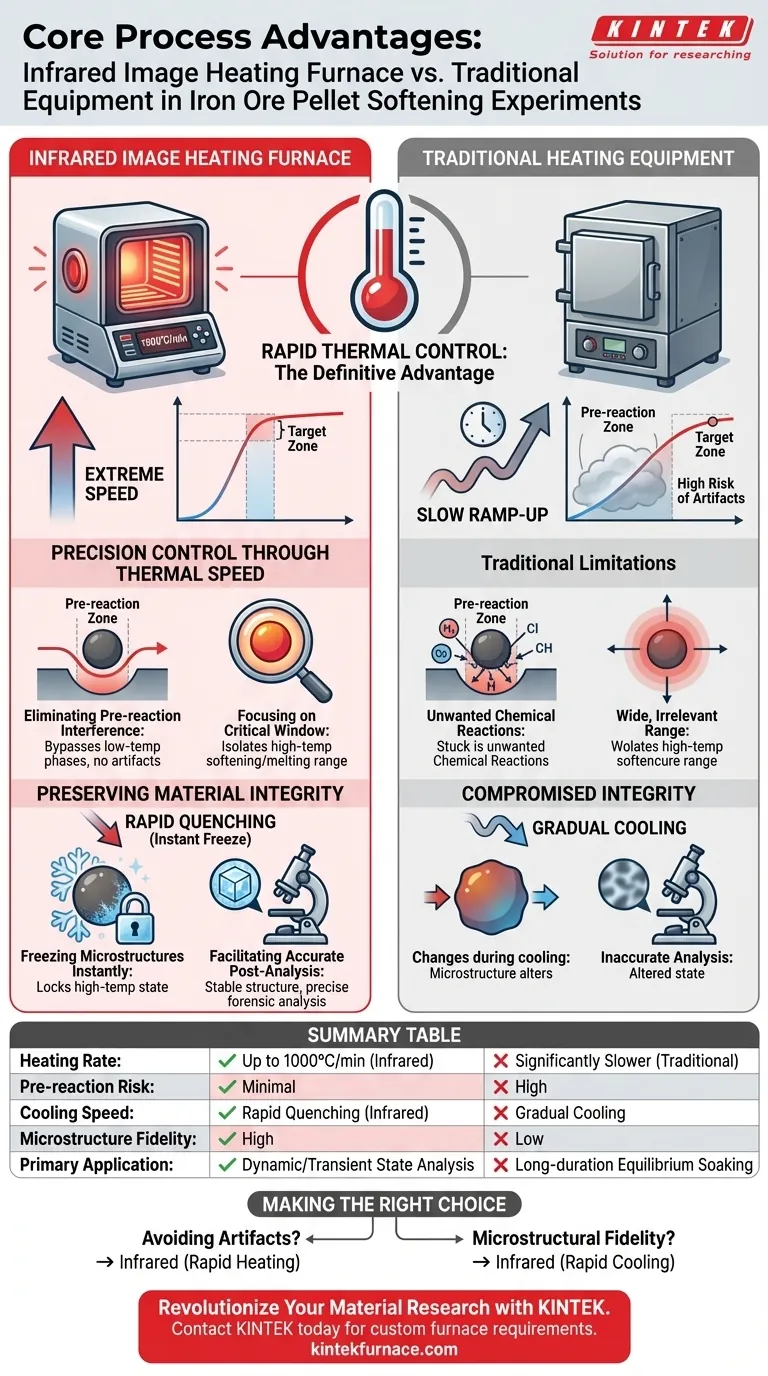

Rapid thermal control is the definitive advantage. An infrared image heating furnace distinguishes itself from traditional equipment through exceptional heating and cooling rates, capable of reaching up to 1000°C/min. This extreme speed allows researchers to bypass irrelevant low-temperature phases and focus entirely on the critical softening and melting behavior of pre-reduced iron ore pellets.

By enabling extreme heating speeds and rapid quenching, infrared furnaces prevent unwanted pre-reactions and "freeze" material states instantly. This ensures that the microstructure analyzed reflects the exact conditions at the target temperature, rather than artifacts formed during slow cooling.

Precision Control Through Thermal Speed

Eliminating Pre-reaction Interference

Traditional heating methods often involve a slow ramp-up in temperature. This creates a window where unwanted chemical reactions can occur before the target zone is reached.

Infrared heating bypasses this issue completely. The rapid heating capability effectively avoids unnecessary pre-reactions. This ensures the pellet reaches the critical softening phase in the exact chemical state intended by the researcher.

Focusing on the Critical Window

Iron ore pellet softening experiments often require data from a very specific, high-temperature range.

This equipment allows you to isolate that range. By accelerating through lower temperatures, the experiment focuses precisely on where pre-reduced pellets soften and melt, maximizing the relevance of the data collected.

Preserving Material Integrity for Analysis

Freezing Microstructures Instantly

The benefits of this technology extend beyond heating; the rapid cooling function is equally critical.

When an experiment concludes, the furnace can drop temperatures quickly. This effectively "locks" the microstructure of the pellets at that specific moment in time.

Facilitating Accurate Post-Analysis

Because the cooling is instant, the physical structure does not change during the cool-down phase.

This stability facilitates accurate subsequent physical structure analysis. Researchers can trust that the sample they examine under a microscope represents the material's state at high temperature, not a state altered by slow cooling.

Operational Considerations

Specificity of Application

While powerful, this technology is specialized. It is designed specifically to capture transient states and high-temperature behaviors.

It is less suited for processes requiring gradual thermal equilibrium or long-duration soaking at lower temperatures. Its primary value lies in dynamic experiments where time and reaction state are critical variables.

Making the Right Choice for Your Experiment

To determine if an infrared image heating furnace is the right tool for your specific iron ore research, consider your primary analytical goals:

- If your primary focus is Avoiding Artifacts: Rapid heating ensures your data is not corrupted by pre-reactions that occur during slow temperature ramp-ups.

- If your primary focus is Microstructural Fidelity: The rapid cooling feature allows you to capture a definitive snapshot of the material's internal structure at the exact moment of melting.

By leveraging these extreme thermal rates, you transform your experiment from a general observation into a precise forensic analysis of material behavior.

Summary Table:

| Feature | Infrared Image Heating Furnace | Traditional Heating Equipment |

|---|---|---|

| Heating Rate | Up to 1000°C/min | Significantly Slower Ramp-up |

| Pre-reaction Risk | Minimal (Bypasses low-temp phases) | High (Slow heating causes artifacts) |

| Cooling Speed | Rapid Quenching (Instant Freeze) | Gradual Cooling |

| Microstructure Fidelity | High (Preserves high-temp state) | Low (Changes during cooling) |

| Primary Application | Dynamic/Transient State Analysis | Long-duration Equilibrium Soaking |

Revolutionize Your Material Research with KINTEK

Don't let slow thermal transitions compromise your experimental data. At KINTEK, we understand that precision in iron ore pellet analysis requires extreme control. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized high-temp furnaces customizable for your unique research needs.

Whether you need to freeze microstructures instantly or eliminate pre-reaction interference, our laboratory solutions provide the reliability you demand. Contact KINTEK today to discuss your custom furnace requirements and ensure your next analysis reflects the exact conditions of your target temperature.

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a vacuum drying oven contribute to biodiesel moisture control? Ensure Fuel Quality & Stability

- Why is a jaw crusher used for initial magnesite ore crushing? Maximize Efficiency & Protect Your Mill

- Why is precise alloy composition adjustment necessary during the preparation of high-performance Cr-Mo-V die steels?

- What is the purpose of using a liquid nitrogen adsorption instrument and BET analysis? Characterize RCM Nanosheets

- What role does a laboratory drying oven play in the formation of polymer colloidal crystal templates? Mastering 3DOM Foundations

- Why is 500°C thermal stabilization necessary for titania supports? Ensure Catalyst Stability and Performance

- How are laboratory ovens and analytical balances used for banana powder moisture content? Precision Testing Guide

- Why is a secondary calcination furnace required after ball milling? Unlock High-Purity Hydroxyapatite Synthesis