Selecting an air atmosphere and air cooling for additive manufactured Inconel 625 parts relies on a specific protocol of heating to 870°C in an electric furnace. This approach is primarily utilized to eliminate residual stress and stabilize the alloy's internal microstructure, offering a practical balance between dimensional stability and mechanical performance.

The core value of this method lies in its ability to provide uniform thermal recovery. It effectively neutralizes the varying stress fields caused by different laser scanning strategies, ensuring consistent material properties regardless of the printing pattern.

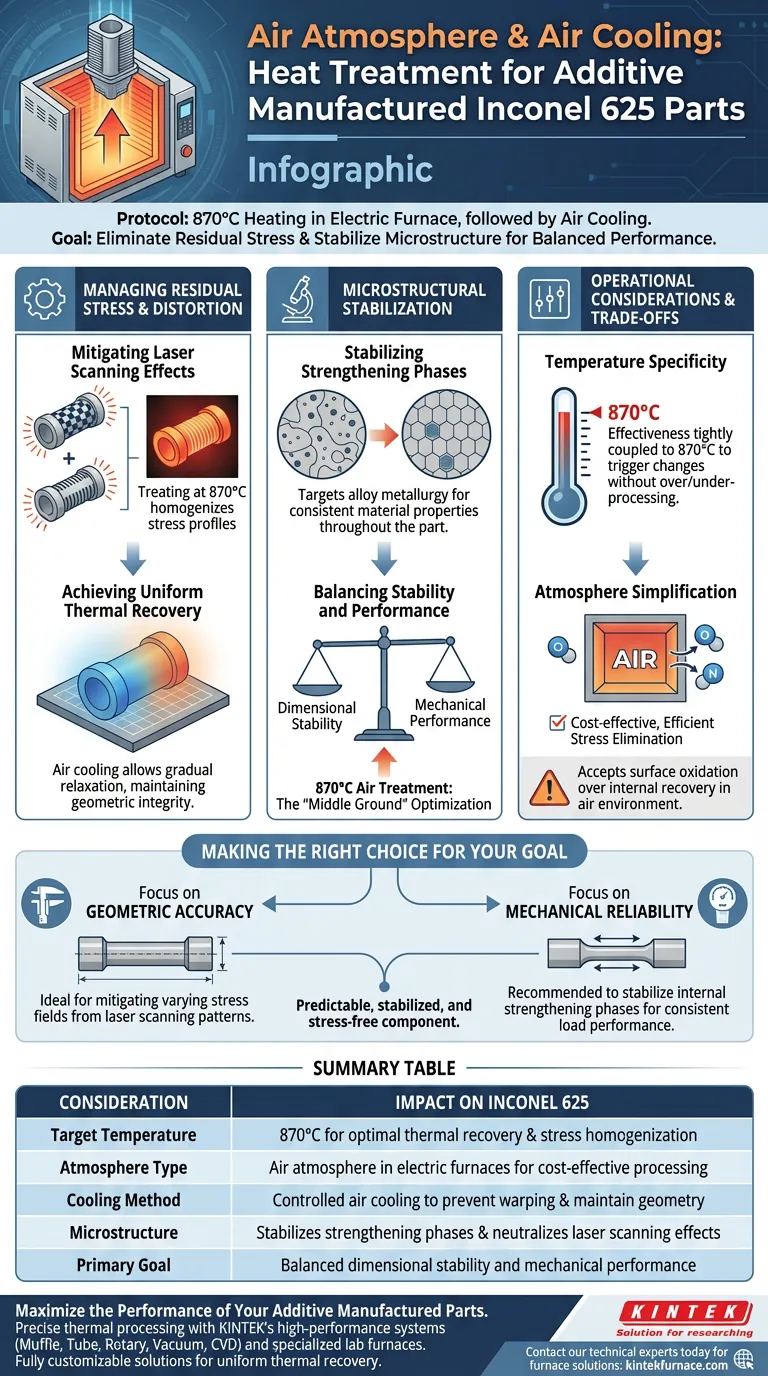

Managing Residual Stress and Distortion

Mitigating Laser Scanning Effects

Additive manufacturing introduces complex stress fields into parts based on how the laser moves. Different strategies, such as checkerboard or strip patterns, create varying residual stress profiles.

Treating the part at 870°C serves to homogenize these differences. The process mitigates the specific stress signatures left by the printing strategy, resetting the material's internal state.

Achieving Uniform Thermal Recovery

The combination of heating and subsequent air cooling provides a uniform thermal recovery effect. This uniformity is critical for preventing warping or distortion after the part is removed from the build plate.

By allowing the part to cool in air, the material relaxes gradually. This helps maintain the geometric integrity of the component while releasing the internal tension built up during the rapid heating and cooling of the printing process.

Microstructural Stabilization

Stabilizing Strengthening Phases

Beyond simple stress relief, this specific thermal cycle targets the alloy's metallurgy. The treatment stabilizes the internal strengthening phases of the Inconel 625.

This stabilization is essential for reliable performance. It ensures that the material's microstructure is consistent throughout the part, rather than varying based on local cooling rates experienced during printing.

Balancing Stability and Performance

The ultimate goal of this protocol is equilibrium. It is designed to balance dimensional stability with mechanical performance.

You are not sacrificing the shape of the part to gain strength, nor are you sacrificing strength to keep the part straight. The 870°C air treatment achieves a "middle ground" optimization suitable for functional components.

Operational Considerations and Trade-offs

Temperature Specificity

The effectiveness of this method is tightly coupled to the 870°C set point. This temperature is specifically selected to trigger the necessary microstructural changes without overheating or under-processing the material.

Atmosphere Simplification

Using an air atmosphere in a standard electric furnace simplifies the operational requirements compared to vacuum or inert gas treatments. However, it implies that the surface chemistry interaction with air at this temperature is acceptable for the application.

The primary trade-off here is accepting an air environment to achieve cost-effective and efficient stress elimination. The process prioritizes internal structural recovery over surface oxidation concerns typically associated with non-vacuum environments.

Making the Right Choice for Your Goal

To determine if this heat treatment protocol aligns with your manufacturing objectives, consider your specific requirements for stress management and mechanical consistency.

- If your primary focus is geometric accuracy: This method is ideal as it mitigates the varying stress fields from laser scanning patterns (like checkerboard or strip) to ensure dimensional stability.

- If your primary focus is mechanical reliability: This approach is recommended to stabilize internal strengthening phases, ensuring the alloy performs consistently under load.

By adhering to the 870°C air atmosphere and air cooling protocol, you ensure a predictable, stabilized, and stress-free component ready for service.

Summary Table:

| Consideration | Impact on Inconel 625 |

|---|---|

| Target Temperature | 870°C for optimal thermal recovery and stress homogenization |

| Atmosphere Type | Air atmosphere in electric furnaces for cost-effective processing |

| Cooling Method | Controlled air cooling to prevent warping and maintain geometry |

| Microstructure | Stabilizes strengthening phases and neutralizes laser scanning effects |

| Primary Goal | Balanced dimensional stability and mechanical performance |

Maximize the Performance of Your Additive Manufactured Parts

Precise thermal processing is the key to unlocking the full potential of Inconel 625. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet your unique metallurgical needs.

Whether you are mitigating residual stress from complex laser patterns or stabilizing alloy microstructures, our equipment ensures the uniform thermal recovery your functional components require.

Ready to elevate your heat treatment precision? Contact our technical experts today to find the perfect furnace solution for your laboratory or production line.

Visual Guide

References

- Alexandru Paraschiv, Mihai Vlăduț. Assessment of Residual Stresses in Laser Powder Bed Fusion Manufactured IN 625. DOI: 10.3390/ma17020413

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the key considerations when using an atmosphere protection muffle furnace? Ensure Safety and Precision for Your Lab

- Why is atmosphere control critical for heat treatment quality? Unlock Precision and Durability

- What additional functionalities does an atmosphere furnace offer compared to a muffle furnace? Unlock Advanced Material Processing

- Why is a nitrogen atmosphere necessary when calcining modified graphite felt? Prevent Burnout & Ensure Purity

- What negative consequences can occur without proper furnace atmosphere control? Avoid Costly Failures and Ensure Safety

- What is the significance of a controlled atmosphere in a retort furnace? Ensure Purity and Precision in Thermal Processing

- What is the purpose of performing heat treatment in a nitrogen atmosphere for ZnS/CeO2? Optimize Your Synthesis Process

- What is the structure of a protective atmosphere box furnace? Unlock Precise Heat Treatment with Controlled Environments