In heat treatment, atmosphere control is the single most critical variable for determining the final quality of a component. The gases surrounding a part at high temperature are not passive; they actively protect, modify, and transfer heat to the material. Failure to precisely manage this atmosphere leads directly to surface defects, inconsistent metallurgical properties, and rejected parts.

A furnace atmosphere is not an empty space—it is an active ingredient in the heat treatment process. Controlling it correctly prevents destructive surface reactions while also enabling the specific metallurgical changes needed to achieve the component's designed performance and reliability.

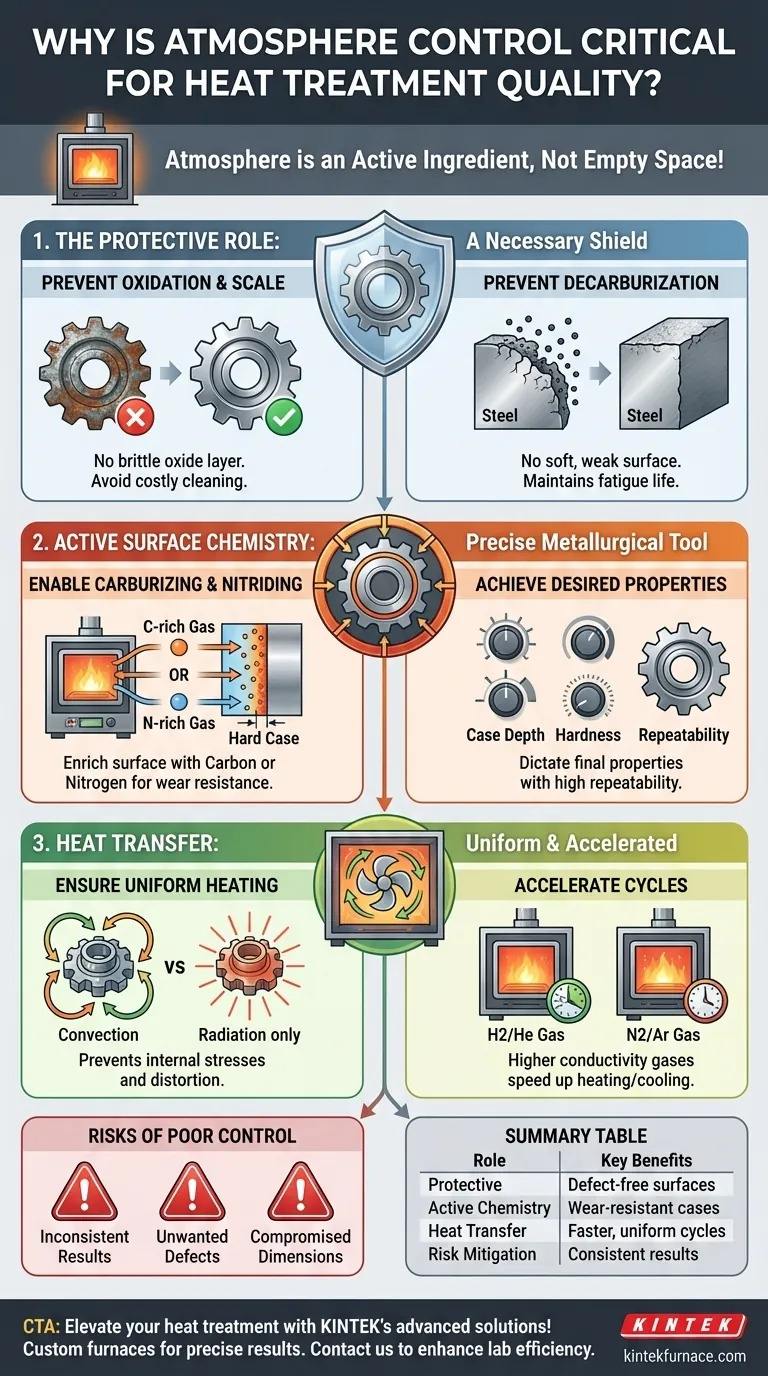

The Protective Role of the Atmosphere

At the elevated temperatures required for heat treatment, metals become highly reactive with the gases found in ambient air, particularly oxygen. An engineered atmosphere provides a necessary shield.

Preventing Oxidation and Scale

When heated in the presence of oxygen, steel and other alloys will rapidly form an oxide layer on the surface, commonly known as scale.

This scale is brittle, alters the part's dimensions, and must be removed through costly secondary operations like sandblasting or chemical cleaning. A controlled, low-oxygen atmosphere prevents this reaction entirely.

Preventing Decarburization

Decarburization is the loss of carbon from the surface of steel. It occurs when the carbon in the steel reacts with oxygen or water vapor in the furnace atmosphere.

This process creates a soft, weak surface layer that dramatically reduces the fatigue life and wear resistance of the component, rendering it unfit for its intended application.

The Active Role in Surface Chemistry

Beyond simple protection, specific atmospheres are designed to intentionally and precisely alter the surface chemistry of a component. This is known as case hardening.

Enabling Carburizing and Nitriding

In processes like carburizing, the furnace atmosphere is enriched with a carbon-bearing gas. This creates a "carbon potential" that forces carbon to diffuse into the surface of the steel.

The result is a part with a soft, tough core and an extremely hard, wear-resistant outer case. Similarly, nitriding uses a nitrogen-rich atmosphere (typically from ammonia) to form hard nitrides on the surface.

Achieving Desired Metallurgical Properties

By precisely controlling the composition of these active atmospheres, metallurgists can dictate the final case depth, surface hardness, and other properties with high repeatability. This transforms the furnace from a simple oven into a precise metallurgical tool.

The Overlooked Role in Heat Transfer

The furnace atmosphere also plays a crucial physical role: it transports thermal energy. The type and pressure of the gas directly impact how quickly and evenly a part heats up.

Ensuring Uniform Heating

Gases within a furnace transfer heat from the heating elements and furnace walls to the workpiece via convection. This is often more effective and uniform than heat transfer by radiation alone (which is the primary method in a vacuum).

A circulating atmosphere helps ensure that all sections of a complex part—thick and thin—reach the target temperature at nearly the same time, preventing internal stresses and distortion.

Accelerating Heat Transfer

Certain gases, like hydrogen and helium, have much higher thermal conductivity than nitrogen or argon. Using them in the atmosphere can significantly accelerate the heating and cooling rates.

This allows for shorter cycle times and, in some cases, can help achieve specific microstructures that are only possible with rapid quenching.

Understanding the Risks of Poor Control

Failing to maintain precise atmospheric conditions introduces unacceptable process variability and risk.

Inconsistent Batch-to-Batch Results

Small, undetected air leaks or fluctuations in gas composition can lead to dramatic differences between production runs. One batch may be perfect, while the next suffers from excessive oxidation or insufficient case depth.

Creation of Unwanted Defects

Even trace amounts of contaminants can cause problems. For example, excessive water vapor in what should be an inert atmosphere can still lead to decarburization and part failure.

Compromised Dimensional Stability

Uncontrolled oxidation or decarburization changes the surface of a part, leading to dimensional inaccuracies. This can make it impossible to hold the tight tolerances required for modern components, leading to scrap.

Making the Right Choice for Your Goal

The ideal atmosphere is determined entirely by the metallurgical goal for the component.

- If your primary focus is simple hardening with no surface change: Use a protective, inert atmosphere like nitrogen or argon to prevent oxidation and decarburization.

- If your primary focus is creating a hard, wear-resistant surface case: Use an active atmosphere with a specific carbon potential (for carburizing) or nitrogen content (for nitriding).

- If your primary focus is process speed and temperature uniformity: Consider an atmosphere with a high-convection gas like hydrogen, while carefully managing the associated safety requirements.

By mastering atmosphere control, you transform heat treatment from an art into a repeatable, precise science.

Summary Table:

| Role of Atmosphere Control | Key Benefits |

|---|---|

| Protective Role | Prevents oxidation, scale, and decarburization for defect-free surfaces |

| Active Surface Chemistry | Enables carburizing and nitriding for hard, wear-resistant cases |

| Heat Transfer Enhancement | Ensures uniform heating and faster cycles with improved thermal conductivity |

| Risk Mitigation | Avoids inconsistent results, defects, and dimensional instability |

Elevate your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior performance and reliability. Contact us today to discuss how we can enhance your lab's efficiency and achieve consistent, high-quality results!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality