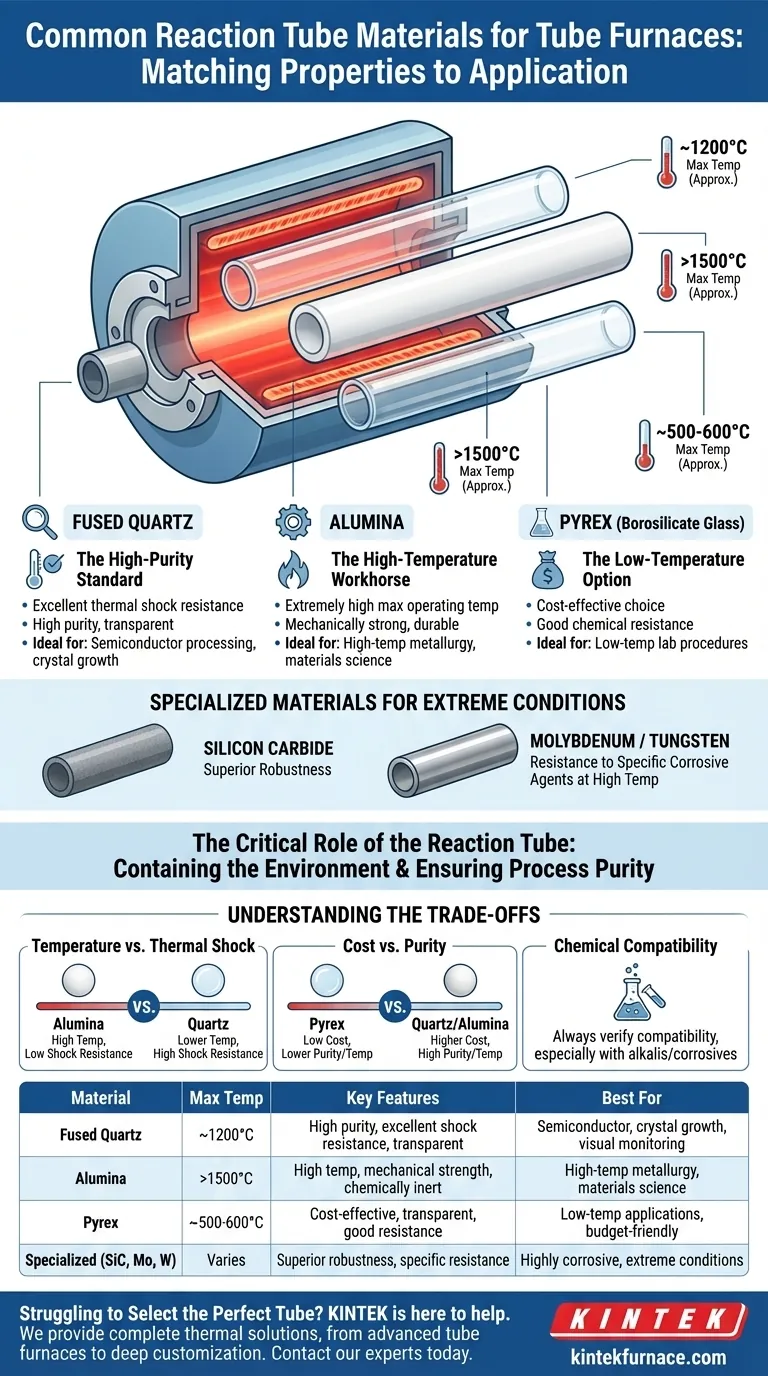

The most common materials for reaction tubes in a tube furnace are alumina, fused quartz, and Pyrex (borosilicate glass). The ideal choice is not a matter of quality but of matching the material's specific properties—like its maximum operating temperature and chemical inertness—to the precise demands of your application. For highly corrosive or specialized conditions, materials such as silicon carbide, molybdenum, or tungsten are also used.

Choosing a furnace tube isn't about finding the single "best" material, but rather understanding the critical trade-offs between a material's maximum temperature, its resistance to thermal shock, and its chemical compatibility with your process.

Understanding the Core Material Properties

The reaction tube is the heart of the furnace, creating the controlled environment where your process takes place. Each material offers a distinct set of advantages.

Fused Quartz: The High-Purity Standard

Fused quartz is a form of high-purity glass valued for its excellent thermal properties and purity. It is a common choice for semiconductor processing and crystal growth.

Its key benefit is a very low coefficient of thermal expansion, which gives it excellent resistance to thermal shock. You can heat and cool it relatively quickly without cracking.

Alumina: The High-Temperature Workhorse

Alumina (Aluminum Oxide, Al₂O₃) is a rugged ceramic known for its extremely high operating temperature and mechanical strength. It is the go-to material for many high-temperature metallurgy and materials science applications.

It is chemically inert in most situations and provides excellent durability. However, it is opaque, which prevents direct visual monitoring of the process inside.

Pyrex (Borosilicate Glass): The Low-Temperature Option

Pyrex is a type of borosilicate glass that serves as a cost-effective option for lower-temperature applications, typically below 500-600°C.

It is transparent and offers good chemical resistance for many common lab procedures, but it cannot handle the extreme temperatures that quartz or alumina can withstand.

Specialized Materials for Extreme Conditions

For processes involving highly corrosive materials or unique physical demands, standard options may not suffice.

Materials like silicon carbide offer superior robustness, while metals like molybdenum and tungsten are used for their resistance to specific corrosive agents at high temperatures.

The Critical Role of the Reaction Tube

The tube does more than just hold the sample; it defines the entire processing environment.

Containing the Environment

The tube acts as a sealed chamber. This allows you to create highly controlled conditions, such as a high-vacuum environment or a specific process atmosphere using inert (e.g., Argon) or reactive gases.

Ensuring Process Purity

The reaction tube must be chemically inert and not react with your sample or process gases at high temperatures. The high thermal stability and chemical resistance of alumina and quartz are precisely why they are chosen for sensitive applications.

Understanding the Trade-offs

Selecting the right material requires balancing competing factors. A mistake here can lead to failed experiments and damaged equipment.

Temperature vs. Thermal Shock

Alumina has a higher maximum operating temperature than quartz, but it is more susceptible to thermal shock. It must be heated and cooled slowly and carefully to prevent cracking.

Quartz handles rapid temperature changes much better, making it more forgiving. However, its maximum continuous-use temperature is lower than alumina's.

Cost vs. Purity

Pyrex is by far the most economical choice but is strictly limited to low-temperature work. High-purity fused quartz and alumina tubes are significantly more expensive but are non-negotiable for achieving reliable high-temperature results.

Chemical Compatibility

While quartz and alumina are highly inert, they are not universally immune. For example, quartz can be attacked by alkalis at high temperatures. Always verify that your chosen tube material is compatible with the specific chemicals in your process.

Making the Right Choice for Your Process

Use your primary process requirement as the deciding factor to guide your selection.

- If your primary focus is maximum temperature and durability (above 1200°C): Alumina is the standard choice, but be sure to program slow heating and cooling rates.

- If your primary focus is high-purity processing and thermal shock resistance: Fused quartz is the ideal material, especially if visual observation of your sample is needed.

- If your primary focus is low-temperature work (below 600°C) on a budget: Pyrex (borosilicate glass) is a perfectly suitable and cost-effective option.

- If your primary focus is handling highly corrosive materials: You must investigate specialized tubes made from materials like silicon carbide or specific metals.

Selecting the correct tube material is the foundational step toward achieving repeatable and reliable results in your high-temperature process.

Summary Table:

| Material | Max Temp (Approx.) | Key Features | Best For |

|---|---|---|---|

| Fused Quartz | ~1200°C | High purity, excellent thermal shock resistance, transparent | Semiconductor processing, crystal growth, processes needing visual monitoring |

| Alumina | >1500°C | High temperature, mechanical strength, chemically inert | High-temperature metallurgy, materials science, durable applications |

| Pyrex (Borosilicate Glass) | ~500-600°C | Cost-effective, transparent, good chemical resistance | Low-temperature applications on a budget |

| Specialized (e.g., SiC, Mo, W) | Varies | Superior robustness, specific chemical resistance | Highly corrosive environments, extreme conditions |

Struggling to Select the Perfect Tube for Your Process?

Choosing the right reaction tube material is critical for the success and safety of your high-temperature applications. The wrong choice can lead to failed experiments, contaminated samples, and damaged equipment.

KINTEK is here to help. We don't just sell tube furnaces; we provide complete thermal solutions. Leveraging our exceptional R&D and in-house manufacturing capabilities, we offer deep customization to ensure your reaction tube precisely matches your unique requirements for temperature, atmosphere, and chemical compatibility.

Our expertise includes:

- Advanced High-Temperature Furnaces: Our product line includes Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems.

- Deep Customization: We tailor reaction tubes and furnace systems to your exact process needs, whether you're working with sensitive materials or highly corrosive environments.

Let's optimize your process together. Contact our experts today for a consultation and ensure you have the right tool for the job.

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab