Industrial high vacuum pyrolysis furnaces differ fundamentally from mechanical methods by utilizing thermal decomposition rather than physical force to separate materials. While mechanical stripping relies on abrasion or crushing, vacuum pyrolysis applies precise heat to break down the chemical bonds of binders, allowing for the clean release of active materials from current collectors.

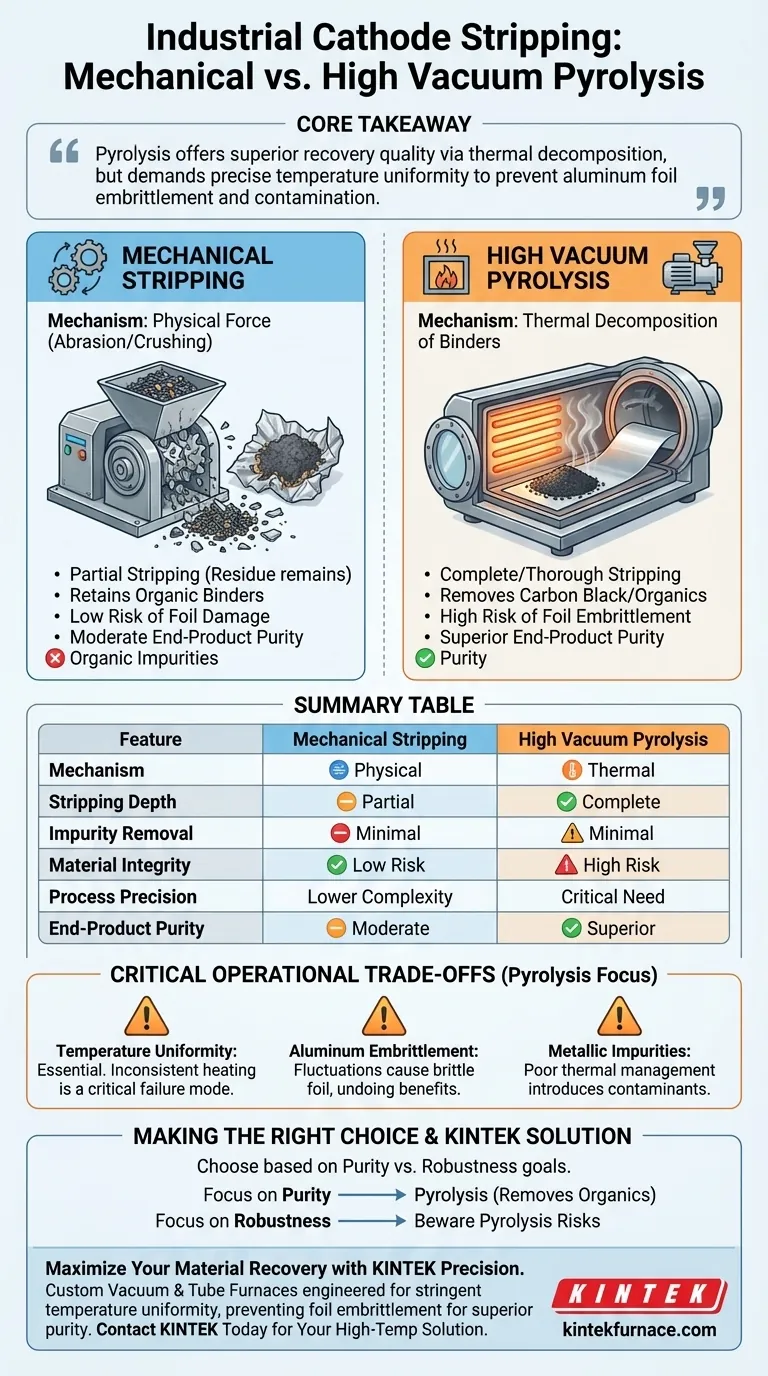

Core Takeaway High vacuum pyrolysis offers a higher quality of material recovery than mechanical methods by effectively eliminating organic impurities and ensuring thorough stripping. However, this method introduces significant technical risks; without precise temperature uniformity, you face the immediate threat of embrittling the aluminum foil and contaminating your material stream.

How Vacuum Pyrolysis Achieves Separation

Thermal Decomposition of Binders

Unlike mechanical methods that physically force materials apart, pyrolysis targets the chemical adhesion.

The furnace uses high temperatures to decompose or carbonize the binders that glue the active materials to the current collectors.

Elimination of Adhesion

Once the binder is chemically altered or destroyed, the adhesion between the layers is effectively eliminated.

This allows the active material to detach naturally without the need for aggressive physical impact that might damage the structure of the materials.

Advantages Over Mechanical Stripping

Superior Stripping Completeness

The primary advantage of pyrolysis is the depth of the separation.

Compared to mechanical techniques, which may leave material clinging to the foil, high vacuum pyrolysis offers more thorough stripping, maximizing the recovery rate of valuable active materials.

Removal of Organic Contaminants

Mechanical separation often fails to address microscopic organic residues.

Pyrolysis excels here by burning off or removing organic impurities, specifically carbon black. This results in a purer end-product compared to the output of purely mechanical lines.

Critical Operational Trade-offs

The Requirement for Temperature Uniformity

The effectiveness of pyrolysis hinges on precision.

The system requires extremely high temperature uniformity throughout the furnace chamber. Inconsistent heating is not a minor efficiency loss; it is a critical process failure mode.

Risk of Aluminum Embrittlement

If temperature control fluctuates or exceeds specific limits, the aluminum foil current collectors can become brittle.

Embrittled foil fragments easily, making it difficult to separate from the active material later, effectively undoing the benefits of the process.

Management of Metallic Impurities

High-temperature processing carries inherent contamination risks.

Poor thermal management can lead to the introduction of excess metallic impurities into the active material. This compromises the purity gained by removing the organic contaminants.

Making the Right Choice for Your Goal

To determine if high vacuum pyrolysis is the correct approach for your facility, weigh the purity requirements against your ability to control thermal variables.

- If your primary focus is Material Purity: Pyrolysis is the superior choice, as it removes organic impurities like carbon black that mechanical methods miss.

- If your primary focus is Process Robustness: Be aware that pyrolysis requires stringent temperature uniformity to avoid the critical pitfalls of foil embrittlement and metallic contamination.

Successful implementation depends less on the furnace's power and more on its ability to maintain a chemically precise thermal environment.

Summary Table:

| Feature | Mechanical Stripping | High Vacuum Pyrolysis |

|---|---|---|

| Mechanism | Physical force (abrasion/crushing) | Thermal decomposition of binders |

| Stripping Depth | Partial (residue often remains) | Complete/Thorough stripping |

| Impurity Removal | Minimal (retains organic binders) | High (removes carbon black/organics) |

| Material Integrity | Low risk of foil damage | High risk of foil embrittlement |

| Process Precision | Lower complexity | Critical need for temperature uniformity |

| End-Product Purity | Moderate | Superior (pure active material) |

Maximize Your Material Recovery with KINTEK Precision

Don't let inconsistent thermal control compromise your cathode recovery. KINTEK provides high-performance, customizable Vacuum and Tube furnace systems engineered specifically for the stringent temperature uniformity requirements of industrial pyrolysis. Our expert R&D and manufacturing team ensures your equipment prevents foil embrittlement while achieving maximum stripping completeness for superior material purity.

Ready to upgrade your battery recycling efficiency?

Contact KINTEK Today to Design Your Custom High-Temp Solution

Visual Guide

References

- Muammer Kaya, Hossein Delavandani. State-of-the-Art Lithium-Ion Battery Pretreatment Methods for the Recovery of Critical Metals. DOI: 10.3390/min15050546

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the key benefits of using a vacuum sintering furnace? Achieve Superior Material Purity and Process Control

- What are the main benefits of using a vacuum furnace for industrial processes? Achieve Superior Material Quality & Control

- What is the function of a dry oxygen thermal oxidation furnace for PERT solar cells? Enhance Efficiency with SiO2

- How are high-temperature vacuum furnaces utilized in scientific research? Unlock Pure, Controlled Material Synthesis

- What is the maximum operating temperature for molybdenum in vacuum furnaces? Key to High-Temp Processing

- Why is a vacuum sintering furnace recommended for high-density MgO? Achieve Near-Zero Porosity & Optical Purity

- How does a high vacuum annealing furnace contribute to 2D Bi2Te3-Sb2Te3 superlattices? Precision Thermal Engineering

- Why is gradient temperature control necessary in an infiltration furnace? Master Sintering Precision