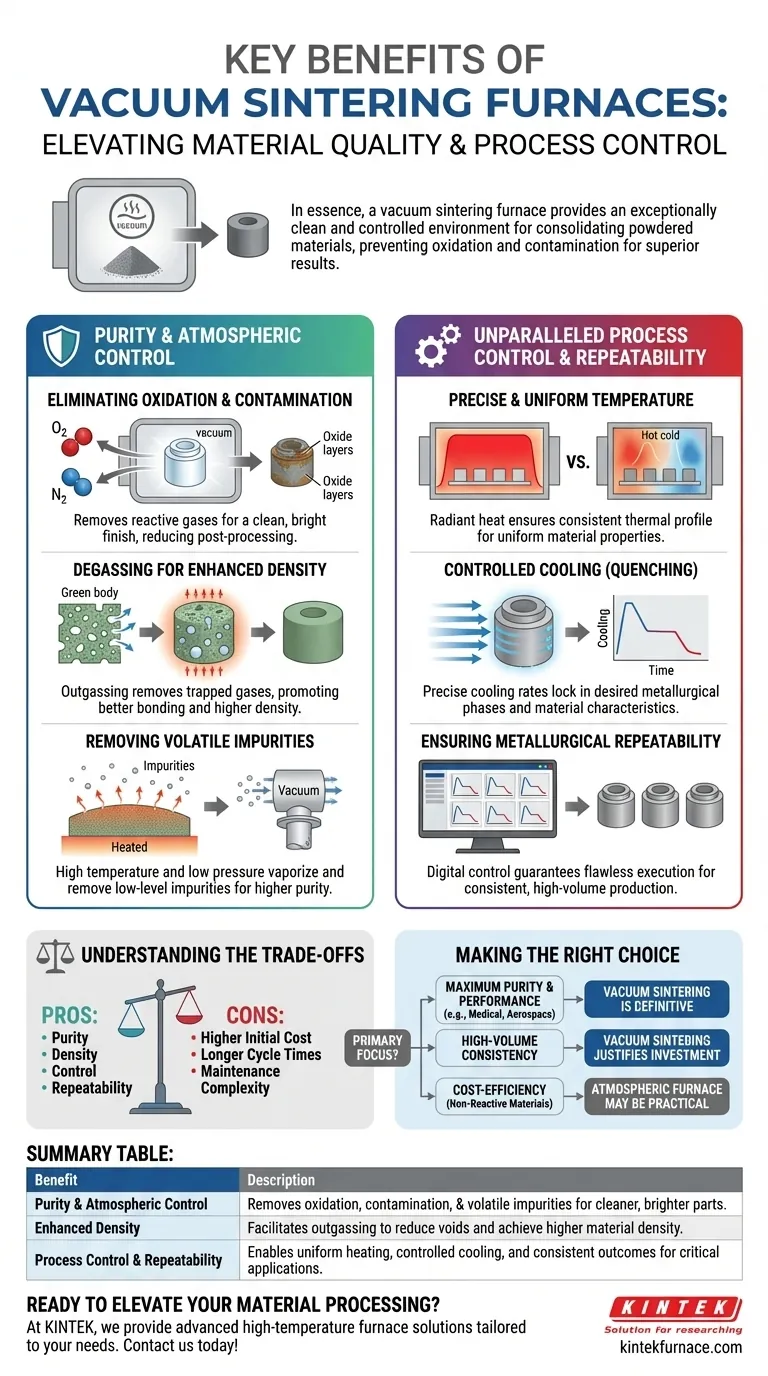

In essence, a vacuum sintering furnace provides an exceptionally clean and controlled environment for consolidating powdered materials. By removing atmospheric gases, it fundamentally prevents oxidation and contamination during the high-temperature process. This results in finished parts with superior material properties, higher density, and a brighter finish, all while enabling precise, repeatable control over the entire thermal cycle.

The primary advantage of vacuum sintering is not merely the prevention of oxidation. It is the active removal of contaminants and adsorbed gases from the material itself, which facilitates superior bonding and leads to fundamentally purer, denser, and more consistent final products.

The Foundation: Purity and Atmospheric Control

The defining characteristic of a vacuum furnace is its ability to manipulate the processing atmosphere, a capability that delivers several critical benefits for material quality.

Eliminating Oxidation and Contamination

In a conventional furnace, the oxygen, nitrogen, and water vapor present in the air react with the material at high temperatures. This forms undesirable oxide and nitride layers on the part's surface.

A vacuum environment removes these reactive gases. The result is a clean, bright part that requires little to no post-process surface cleaning, reducing both labor and material wastage.

Degassing for Enhanced Density

Powdered materials inherently contain adsorbed gases on their particle surfaces and trapped air within the compacted part (the "green body").

During heating under vacuum, these gases are pulled out of the part. This outgassing is critical because it removes barriers between material particles, promoting more effective shrinkage and diffusion bonding. This leads directly to parts with higher final density and fewer internal voids or defects.

Removing Volatile Impurities

The combination of high temperature and low pressure can cause certain low-level impurities within the material, such as silicon or aluminum in some alloys, to vaporize.

The vacuum system then actively pumps these vaporized contaminants away from the product, resulting in a higher-purity final material with more stable and predictable properties.

Unparalleled Process Control and Repeatability

Beyond purity, the vacuum environment enables a level of process control that is unattainable in atmospheric furnaces, leading to highly consistent outcomes.

Precise and Uniform Temperature

In the absence of air, heat transfer occurs primarily through radiation, not convection. This allows for extremely uniform heating across the entire workload, eliminating the hot and cold spots common in conventional furnaces.

This uniformity ensures that every part in a batch, and the entirety of each individual part, experiences the exact same thermal profile. This is key to achieving consistent material properties like hardness and grain structure.

Controlled Cooling (Quenching)

Modern vacuum furnaces can incorporate rapid cooling systems. After the sintering cycle, an inert gas can be introduced and circulated at high velocity to quench the product.

This allows for precise control over the cooling rate, which is a critical step for locking in desired metallurgical phases and achieving specific material hardness and strength characteristics.

Ensuring Metallurgical Repeatability

The entire process—from the vacuum pump-down rate to the temperature ramps, holds, and cooling profile—is typically managed by a computer.

This digital control ensures that the exact same process can be executed flawlessly time after time. For industries like aerospace, medical, and electronics, this guaranteed repeatability is non-negotiable for quality assurance.

Understanding the Trade-offs

While powerful, vacuum sintering is not the universal solution for every application. Objectivity requires acknowledging its specific challenges.

Higher Initial Capital Cost

Vacuum furnaces are complex systems involving vacuum chambers, high-performance pumps, and sophisticated control instrumentation. This results in a significantly higher upfront investment compared to standard atmospheric furnaces.

Potentially Longer Cycle Times

Achieving a deep vacuum requires time for the pumps to evacuate the chamber, a step known as "pump-down." This can extend the overall process cycle, especially when compared to simply heating an atmospheric furnace.

Maintenance Complexity

The components that enable the benefits of a vacuum furnace—pumps, seals, valves, and sensors—require specialized knowledge for proper maintenance and troubleshooting. This can represent a higher ongoing operational cost and skill requirement.

Making the Right Choice for Your Application

Selecting the right sintering technology depends entirely on your material requirements and performance goals.

- If your primary focus is maximum material purity and performance: For reactive materials (like titanium) or applications demanding the highest density and strength (e.g., medical implants, aerospace turbines), vacuum sintering is the definitive choice.

- If your primary focus is high-volume consistency: For producing critical components where every part must meet identical, tight specifications, the process control and repeatability of a vacuum furnace justify the investment.

- If your primary focus is cost-efficiency for non-reactive materials: For materials that are not sensitive to oxidation and where good, but not flawless, density is acceptable, a less expensive atmospheric or inert gas furnace may be the more practical solution.

Ultimately, choosing a vacuum furnace is a decision to prioritize absolute material quality and process control over initial equipment cost.

Summary Table:

| Benefit | Description |

|---|---|

| Purity & Atmospheric Control | Removes oxidation, contamination, and volatile impurities for cleaner, brighter parts. |

| Enhanced Density | Facilitates outgassing to reduce voids and achieve higher material density. |

| Process Control & Repeatability | Enables uniform heating, controlled cooling, and consistent outcomes for critical applications. |

| Trade-offs | Higher initial cost, longer cycle times, and increased maintenance complexity. |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is designed for industries like aerospace and medical that demand superior quality. With strong deep customization capabilities, we can precisely meet your unique experimental requirements. Contact us today to discuss how our vacuum sintering furnaces can enhance your lab's efficiency and deliver consistent, high-performance results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement