In scientific research, high-temperature vacuum furnaces are not merely ovens; they are precision instruments for creating and analyzing materials in an environment free from atmospheric contamination. They are fundamentally used for three core purposes: synthesizing novel materials with extreme purity, simulating processes under extreme conditions, and refining the properties of high-performance components for fields like materials science, physics, and chemistry.

The true value of a high-temperature vacuum furnace in research is its ability to create a highly controlled, ultra-pure environment. This removes the variable of atmospheric reaction, allowing scientists to isolate and study the fundamental properties and behaviors of materials under heat.

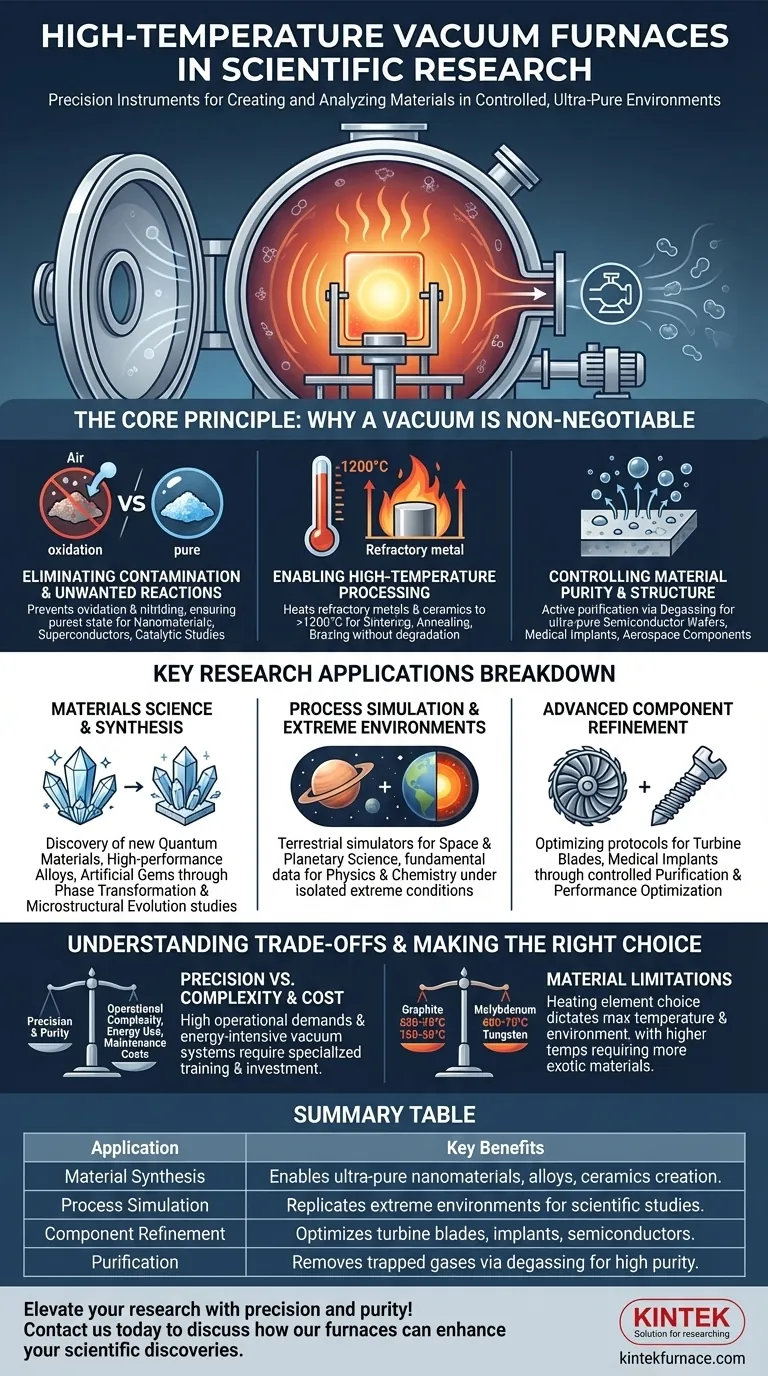

The Core Principle: Why a Vacuum is Non-Negotiable

A vacuum furnace's primary function is to remove the atmosphere—and its reactive gases—from the heating chamber. This capability is the foundation upon which its research applications are built.

Eliminating Contamination and Unwanted Reactions

Most materials, especially at high temperatures, will react with gases like oxygen and nitrogen. This leads to oxidation and nitriding, which fundamentally alter the material's composition and properties.

A vacuum environment eliminates these unwanted reactions. This ensures that the material being studied is in its purest possible state, which is critical for nanomaterials, superconducting materials, and catalytic reaction studies where even trace impurities can invalidate results.

Enabling High-Temperature Processing

Many advanced materials, such as refractory metals and certain ceramics, have processing temperatures that would cause them to instantly combust or degrade in the presence of air.

The vacuum makes it possible to heat these materials to temperatures exceeding 1200°C for processes like sintering, annealing, or brazing without destroying them.

Controlling Material Purity and Structure

A vacuum is also an active tool for purification. The process of degassing uses heat and low pressure to pull trapped gases out from within a material's structure.

This is essential for creating the ultra-pure, structurally sound materials required for semiconductor wafers, medical implants, and aerospace components where internal imperfections could lead to catastrophic failure.

Key Research Applications Breakdown

By providing this controlled environment, vacuum furnaces enable a wide range of specific research activities across multiple disciplines.

Materials Science and Synthesis

The primary use is in the discovery and creation of new materials. Researchers use vacuum furnaces to study phase transformation processes and microstructural evolution as a material is heated and cooled.

This precise control is how new quantum materials, high-performance alloys, and artificial gems are synthesized and their properties optimized.

Process Simulation and Extreme Environments

These furnaces act as terrestrial simulators for extraterrestrial or subterranean conditions. In earth and planetary sciences, they can replicate the high-temperature, low-pressure environments found in space or deep within the planet.

In physics and chemistry, they allow researchers to study how materials behave under extreme conditions in a completely isolated system, providing foundational data for theoretical models.

Advanced Component Refinement

Research often involves perfecting the processes that create finished products. A laboratory vacuum furnace allows scientists to test and refine treatments for components like turbine blades or biocompatible medical implants.

By systematically adjusting temperature, time, and vacuum levels, researchers can determine the optimal protocols for purification and performance optimization before scaling up for industrial production.

Understanding the Trade-offs and Operational Demands

While indispensable, high-temperature vacuum furnaces are complex systems with significant operational considerations.

Precision vs. Complexity

The ability to program precise heating and cooling ramps, control vacuum levels, and ensure safety comes with significant operational complexity. These are not simple "plug-and-play" devices and require specialized training to operate effectively.

Material and Temperature Limitations

The choice of heating elements (e.g., graphite, molybdenum, tungsten) and insulation directly dictates the furnace's maximum temperature and operating environment. This creates inherent limitations and cost implications, as higher-temperature capabilities require more exotic and expensive materials.

The Cost of Purity

Achieving and maintaining a high vacuum is an energy-intensive process that requires a sophisticated system of pumps, valves, and gauges. The financial and maintenance overhead for the vacuum system is a significant factor in the total cost of ownership for any research lab.

Making the Right Choice for Your Research Goal

The specific utility of a vacuum furnace is directly tied to your primary scientific objective.

- If your primary focus is novel material synthesis: You need the furnace to guarantee absolute purity and precisely control the growth conditions required for creating new alloys, ceramics, or nanomaterials.

- If your primary focus is process development: Use the furnace as a testbed to anneal, sinter, or degas components to systematically optimize their final mechanical and chemical properties.

- If your primary focus is fundamental physics or chemistry: The furnace serves as an isolated simulation chamber to study material behavior under extreme, controlled conditions, free from atmospheric interference.

Ultimately, a high-temperature vacuum furnace empowers you to move beyond observing nature and begin creating it with intention.

Summary Table:

| Application | Key Benefits |

|---|---|

| Material Synthesis | Enables creation of ultra-pure nanomaterials, alloys, and ceramics without atmospheric interference. |

| Process Simulation | Replicates extreme environments for physics, chemistry, and planetary science studies. |

| Component Refinement | Optimizes properties of turbine blades, medical implants, and semiconductors through controlled heating. |

| Purification | Removes trapped gases via degassing for high-purity materials in aerospace and electronics. |

Elevate your research with precision and purity! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for materials science, physics, and chemistry labs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your scientific discoveries and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control