In essence, the primary advantages of a rotary kiln are its unique ability to process a wide variety of materials at high volumes with exceptional uniformity and reliability. By combining mechanical tumbling with precise thermal control, these systems deliver consistent, high-quality results in demanding, continuous-operation environments, making them a cornerstone of heavy industry.

A rotary kiln's true value lies not just in its ability to heat materials, but in its dynamic process. By continuously tumbling materials through controlled heating zones, it ensures unparalleled uniformity and high throughput for granular solids, making it a workhorse for industrial-scale thermal processing.

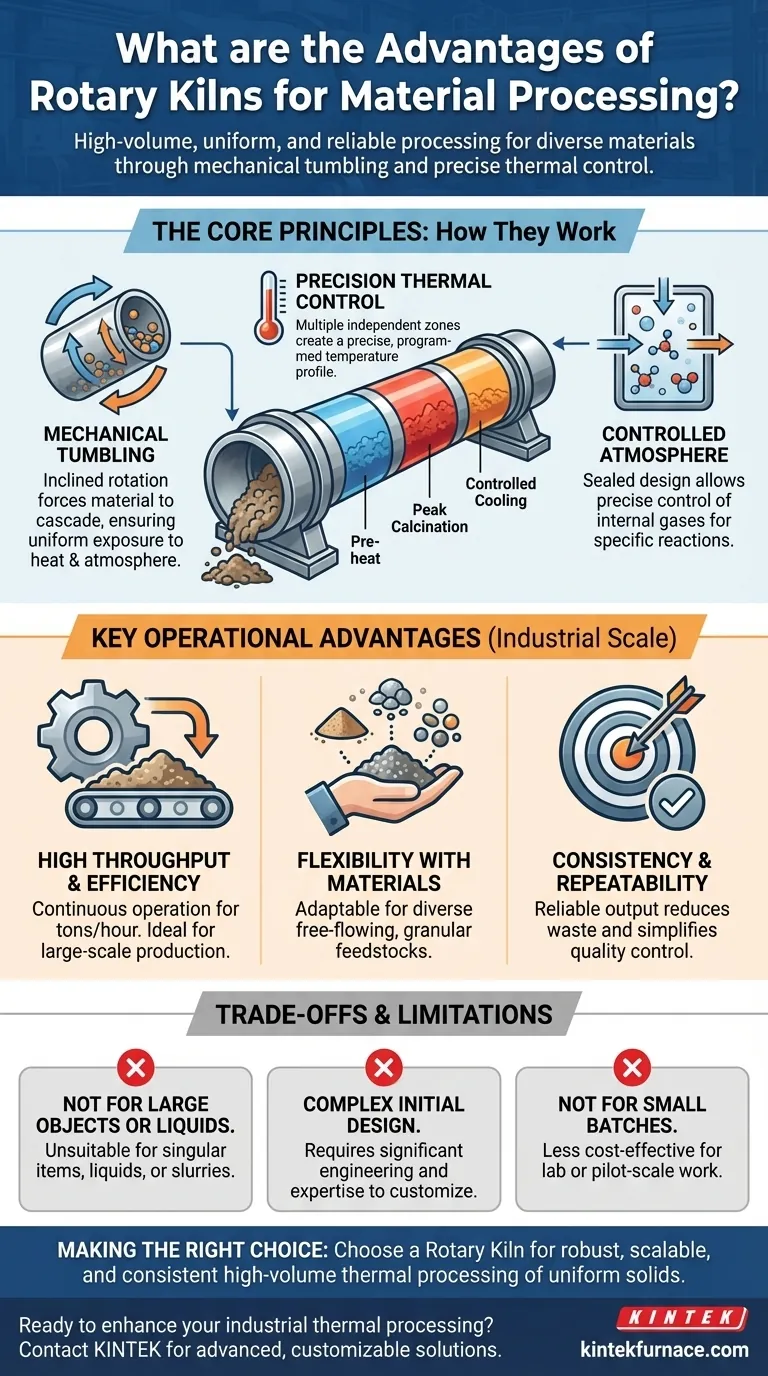

The Core Principles: How Rotary Kilns Achieve Their Advantages

To understand the benefits of a rotary kiln, it's crucial to understand its fundamental design. It is not simply a hot tube; it is an active processing environment.

The Role of Mechanical Tumbling

A rotary kiln is a cylindrical vessel, inclined at a slight angle and rotated slowly on its axis. This design forces the material to cascade and tumble as it travels from the feed end to the discharge end.

This constant mixing is the key to uniform processing. Every particle is repeatedly exposed to the heat source and the internal atmosphere, eliminating hot spots and ensuring the entire batch receives the same treatment.

Precision in Thermal Control

Modern kilns feature multiple, independent heating zones along their length. This allows for a precise temperature profile to be programmed for the material.

A process might require a gentle pre-heating stage, a rapid ramp-up to a peak calcination temperature, and a controlled cooling period. A rotary kiln executes this sequence flawlessly within a single, continuous operation.

Control Over the Internal Atmosphere

The kiln is sealed at both ends, allowing for precise control of the internal atmosphere. This is critical for processes that require specific chemical reactions.

Whether the goal is oxidation, reduction, or simply preventing unwanted reactions with air, the controlled atmosphere ensures the desired chemical or physical transformation occurs efficiently and repeatably.

Key Operational Advantages for Industrial Scale

The engineering principles translate directly into tangible benefits for large-scale production.

High Throughput and Efficiency

The continuous, flowing nature of a rotary kiln makes it ideal for high-volume production. Unlike a batch process, which requires loading, heating, cooling, and unloading, a rotary kiln processes material without interruption.

This continuous operation, combined with high-speed cycle capabilities and efficient heat transfer, makes it an economical solution for processing tons of material per hour.

Flexibility with Diverse Materials

Rotary kilns are renowned for their heavy-duty construction and adaptability. Their modular design allows them to be customized for specific project requirements and challenging conditions.

They excel at processing a wide range of free-flowing, granular materials, from fine powders and small waste stones to larger granular solids, providing a uniform result even with varied feedstocks.

Consistency and Repeatability

For industrial applications, repeatable quality is non-negotiable. The combination of precise temperature control, a controlled atmosphere, and uniform material mixing guarantees a consistent output.

This reliability reduces waste, ensures the final product meets specification, and simplifies quality control.

Understanding the Trade-offs and Limitations

While powerful, a rotary kiln is not the universal solution for all thermal processing. Its strengths define its limitations.

Ideal for Granular and Free-Flowing Materials

The tumbling action that ensures uniformity in powders and aggregates makes a rotary kiln unsuitable for processing large, singular objects or materials that could be damaged by tumbling.

Likewise, it is not designed for processing liquids or slurries without significant upstream preparation like drying and agglomeration. Static batch or belt furnaces are better suited for these applications.

Complexity in Initial Design

The high degree of customization means that a rotary kiln is not an off-the-shelf product. The initial design, engineering, and installation require significant expertise to match the kiln's parameters to the specific material and process goals.

This initial complexity, however, is what unlocks its long-term efficiency and reliability once it is commissioned.

Scale of Operation

Rotary kilns are built for industrial throughput. While highly economical at scale, their operational footprint and energy consumption may make them less cost-effective for small-batch laboratory work or pilot-scale production. For these needs, a smaller tube or box furnace is often a more practical choice.

Making the Right Choice for Your Process

Your specific goal will determine if a rotary kiln is the right technology for you.

- If your primary focus is high-volume production of uniform solids: The rotary kiln is the definitive choice for its continuous processing capability and superior mixing action.

- If your primary focus is processing varied or inconsistent raw materials: The kiln's robust and adaptable nature makes it a strong contender, provided the materials are granular or can be made to be.

- If your primary focus is precise, static treatment of individual parts or small batches: A different solution, such as a batch furnace or tube furnace, will likely be more suitable and cost-effective.

Ultimately, selecting a rotary kiln is a decision for robust, scalable, and consistent thermal processing.

Summary Table:

| Advantage | Description |

|---|---|

| High Throughput | Continuous operation for processing tons of material per hour, ideal for large-scale production. |

| Uniform Processing | Mechanical tumbling ensures consistent exposure to heat, eliminating hot spots and ensuring batch uniformity. |

| Flexibility | Adaptable for a wide range of granular and free-flowing materials, with customization for specific needs. |

| Controlled Atmosphere | Sealed design allows precise control of internal conditions for oxidation, reduction, or other reactions. |

| Reliability | Consistent, repeatable results reduce waste and simplify quality control in demanding environments. |

Ready to enhance your industrial thermal processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our rotary kilns can deliver high-volume, uniform results for your material processing needs!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency