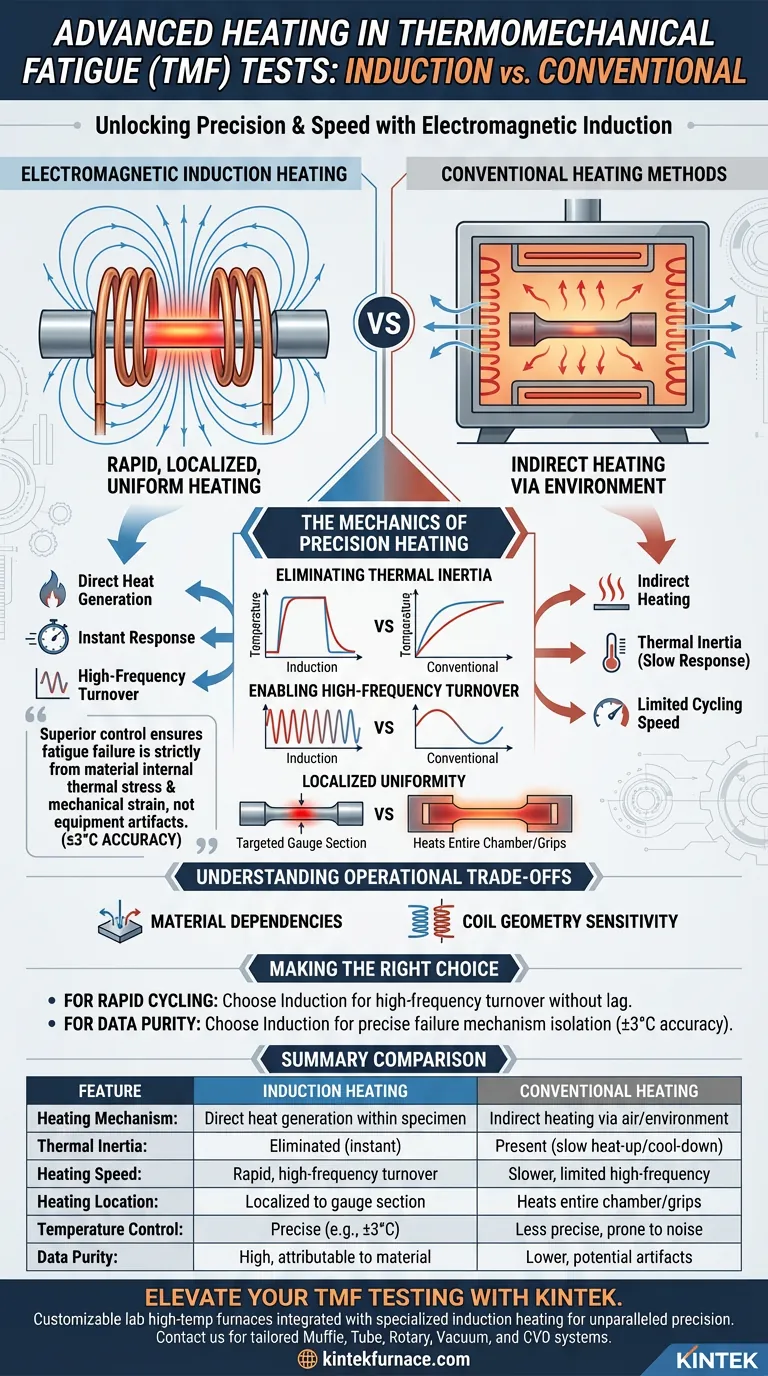

Electromagnetic induction heating coils provide a critical advantage in thermomechanical fatigue (TMF) testing by delivering rapid, localized, and uniform heating directly to the specimen's gauge section. Unlike conventional heating methods, induction eliminates the lag caused by equipment thermal inertia, allowing for high-frequency thermal turnover while maintaining precise temperature control within ±3°C.

The superior control offered by induction heating ensures that any observed fatigue failure is strictly derived from the material's internal coupling of thermal stress and mechanical strain, rather than artifacts of the testing equipment.

The Mechanics of Precision Heating

To understand the superiority of induction coils in this context, one must look at how they manage energy compared to general heating methods.

Eliminating Thermal Inertia

Conventional heating methods, such as furnaces, heat the air or the surrounding environment to heat the specimen. This creates thermal inertia, meaning the equipment takes time to heat up and cool down.

Induction heating bypasses this by generating heat directly within the material. This allows the system to respond instantly to temperature command changes, removing the lag inherent in traditional methods.

Enabling High-Frequency Turnover

TMF testing often requires the material to undergo rapid cycles of heating and cooling to simulate real-world stress.

Because induction coils avoid thermal inertia, they facilitate high-frequency thermal turnover. The system can ramp temperatures up and down quickly, matching the rigorous speed requirements of modern fatigue testing protocols.

Localized Uniformity

General heating methods tend to heat the entire testing chamber or large portions of the grip assembly.

Induction coils are designed to provide localized heating, targeting only the gauge section of the specimen. This ensures the thermal stress is applied exactly where the strain is being measured, without compromising the surrounding test rig components.

Understanding the Operational Trade-offs

While induction heating offers superior precision, it introduces specific constraints that must be managed to ensure valid results.

Material Dependencies

Induction heating relies on electromagnetic coupling. Therefore, its efficiency is directly tied to the electrical and magnetic properties of the specimen material.

Coil Geometry Sensitivity

To achieve the uniform heating mentioned in the primary reference, the coil design must be closely matched to the specimen's geometry. Poor coil alignment or design can lead to uneven heating profiles, violating the ±3°C accuracy requirement.

Making the Right Choice for Your Goal

The choice between induction and conventional heating often comes down to the specific requirements of your fatigue cycles.

- If your primary focus is rapid cycling: Induction heating is essential to achieve the high-frequency thermal turnover required without equipment lag.

- If your primary focus is data purity: Use induction to ensure failure mechanisms are caused solely by thermal-mechanical coupling, maintaining accuracy within ±3°C.

By removing external thermal noise, induction heating transforms TMF testing from a rough approximation into a precise material science discipline.

Summary Table:

| Feature | Electromagnetic Induction Heating | Conventional Heating Methods |

|---|---|---|

| Heating Mechanism | Direct heat generation within specimen | Indirect heating via surrounding environment/air |

| Thermal Inertia | Eliminated (instant response) | Present (slow heat-up/cool-down) |

| Heating Speed | Rapid, high-frequency thermal turnover | Slower, limited high-frequency cycling |

| Heating Location | Localized to specimen gauge section only | Heats entire chamber or large grip assembly sections |

| Temperature Control | Precise (e.g., ±3°C accuracy) | Less precise, prone to external thermal noise |

| Data Purity | High, failure mechanisms attributed directly to material | Lower, potential artifacts from equipment thermal lag |

Elevate your thermomechanical fatigue testing with KINTEK's advanced heating solutions. Our customizable lab high-temp furnaces, backed by expert R&D and manufacturing, can integrate specialized heating methods like induction coils to achieve the unparalleled precision and high-frequency thermal turnover your research demands. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum, and CVD systems can be tailored for your unique testing needs, ensuring superior material analysis and data purity.

Visual Guide

References

- Yasha Yuan, Jingpei Xie. Strain-Controlled Thermal–Mechanical Fatigue Behavior and Microstructural Evolution Mechanism of the Novel Cr-Mo-V Hot-Work Die Steel. DOI: 10.3390/ma18020334

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Vacuum Heat Treat Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- How do the different types of silicon carbide heating elements compare in terms of applications? Find the Best Fit for Your High-Temp Needs

- How does the high-temperature antioxidant property of MoSi2 heating elements work? Unlock Longevity with Self-Healing Protection

- What are the advantages of using T-type fine-wire thermocouples for monitoring coal pyrolysis pretreatment?

- Why is thermal strain simulation analysis essential? Ensure Maximum Reliability in Industrial Radiant Tubes

- What are some high-temperature heating elements used in laboratory vacuum furnaces and what temperatures can they achieve? Discover the Best Options for Your Lab

- What role do silicon carbide heating elements play in ceramics and glass manufacturing? Achieve Superior Heat Control and Efficiency

- What are the three main classification frameworks for heating elements? Choose the Right Type for Your Application